Electromagnetic semicontinuous casting method of aluminium alloy pipe material and its casting device

An aluminum alloy and semi-continuous casting technology is applied in the field of aluminum alloy pipe casting to achieve the effects of uniform structure, uniform circumferential temperature and wide adjustment range of magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

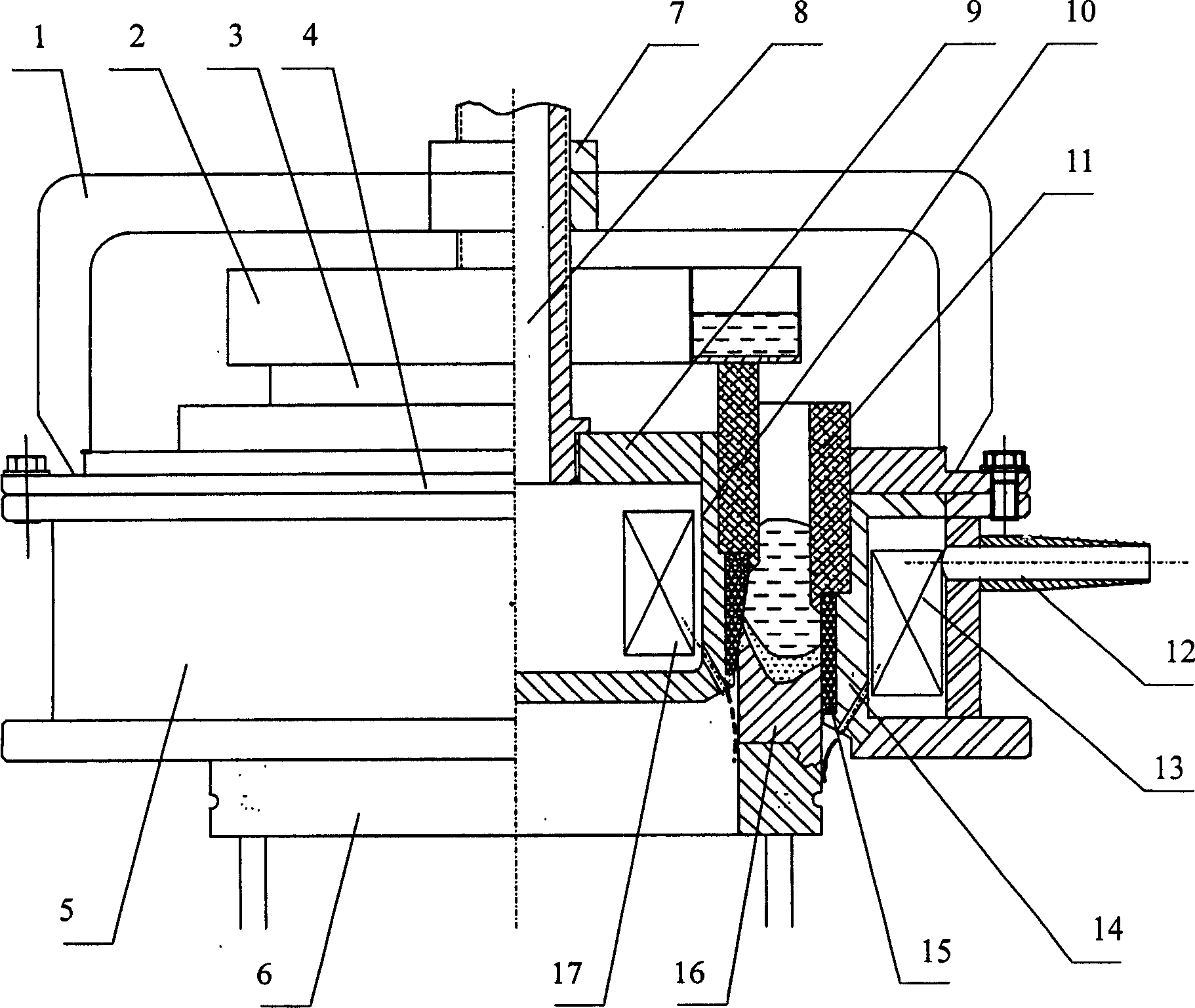

[0029] Such as figure 1 As shown, the aluminum alloy pipe electromagnetic semi-continuous casting casting device of the present invention includes: 1 bracket, 2 rain-type launders, 3 inner hot tops, 4 glands, 5 outer mold jackets, 6 dummy bases, 7 nuts, 8 inner crystallizer inlet water pipe, 9 inner mold upper cover, 10 inner mold body, 11 outer heat top, 12 outer mold inlet water pipe, 13 outer coil, 14 outer mold inner sleeve, 15 stone grinding ring, 16 aluminum Alloy cast pipe, 17 inner coils. After the outer mold inner sleeve 14 and the outer mold outer sleeve 5 are combined, they are fixed with a gland 4 to form an outer mold water cooling chamber, and the outer coil 13 is placed in the outer mold water cooling chamber; the outer mold inner sleeve 14 is embedded with an outer The hot top 11, the stone grinding ring 15; the inner crystallizer body 10 and the inner mold upper cover 9 are combined to form the inner mold water-cooling chamber, and the inner coil 17 is placed...

Embodiment 2

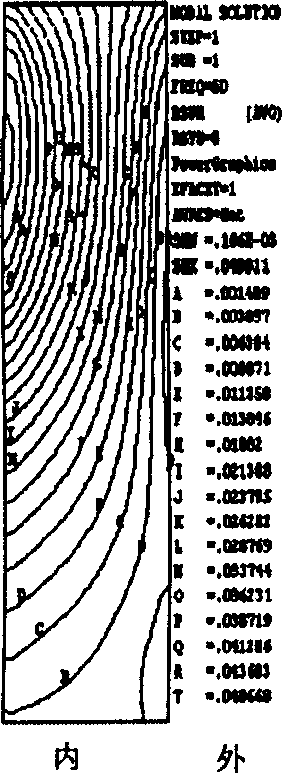

[0032] Different phase power frequency electromagnetic continuous casting

[0033] Ingot size: φ290mm×35mm, stainless steel dummy base

[0034] Magnetic field conditions: inner coil: ampere-turns 14400AT; outer coil: ampere-turns 6000AT; frequency 50Hz; outer coil current

[0035] 50° phase lag behind the inner coil

[0036] Process parameters: the casting temperature is 750°C, and the casting speed is 140mm / min.

[0037] casting method

Embodiment 3

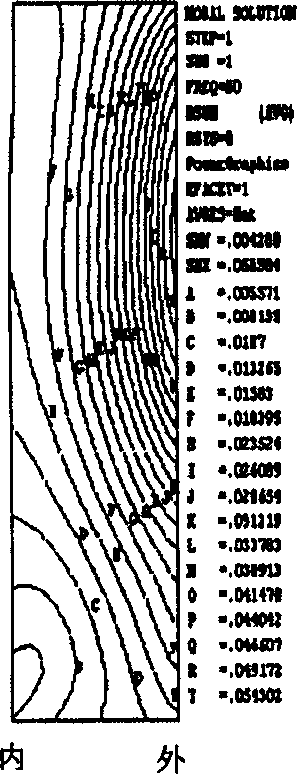

[0039] Low Frequency Electromagnetic Continuous Casting

[0040] Ingot size: φ290mm×35mm, stainless steel dummy base

[0041] Magnetic field conditions: inner coil: ampere-turns 12000AT; outer coil: ampere-turns 5000AT; frequency 30Hz; outer coil current

[0042] Phase lag of inner coil 0°

[0043] Process parameters: casting temperature 750°C, casting speed 140mm / min.

[0044] casting method

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com