Air inlet structure for engine

A technology of air intake structure and engine, which is applied in the field of vehicles, can solve problems such as the smaller configuration space of air intake system components, the inability to arrange resonators and throttle bodies close to each other, and achieve the effect of expanding the installation and placement space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

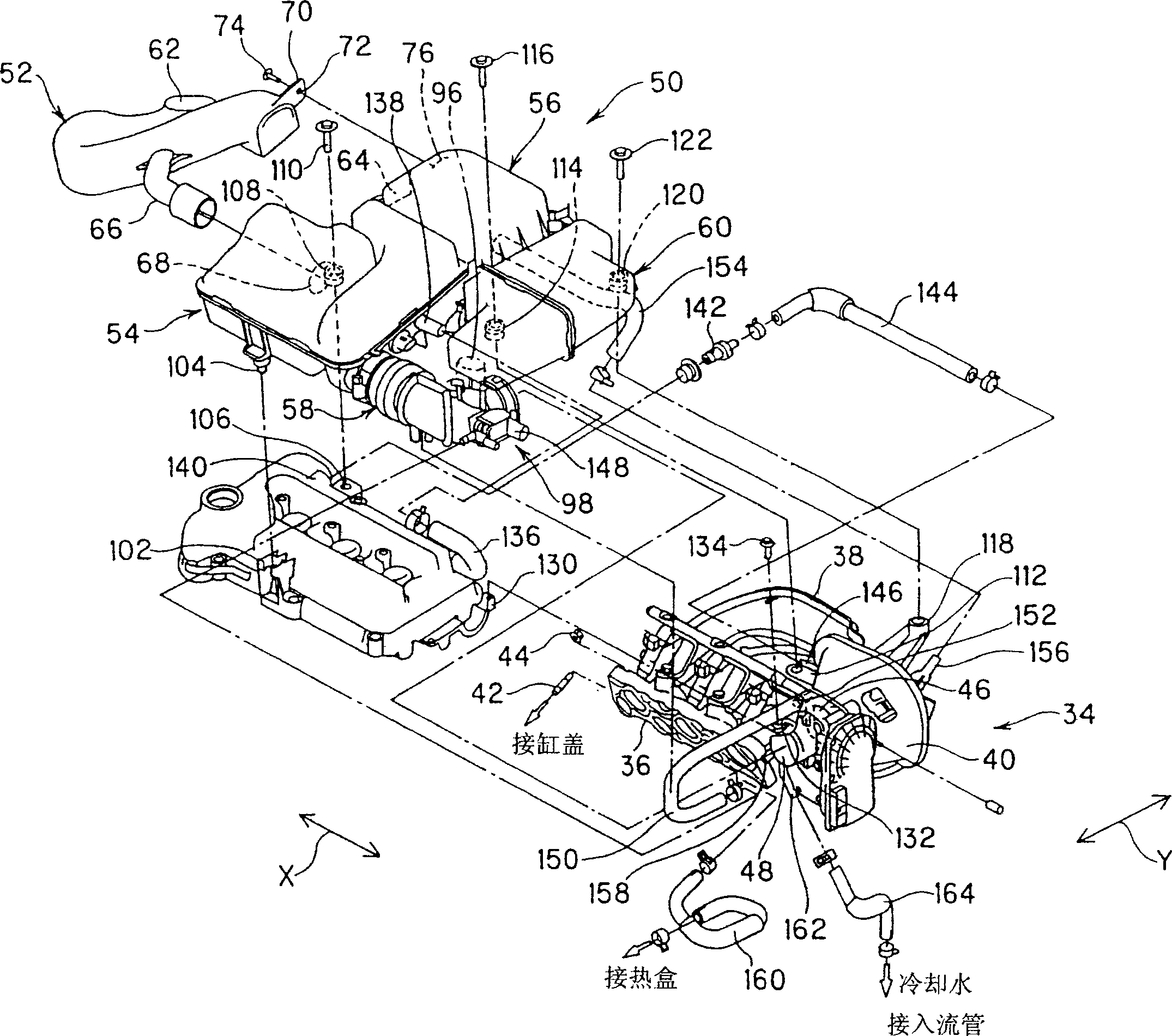

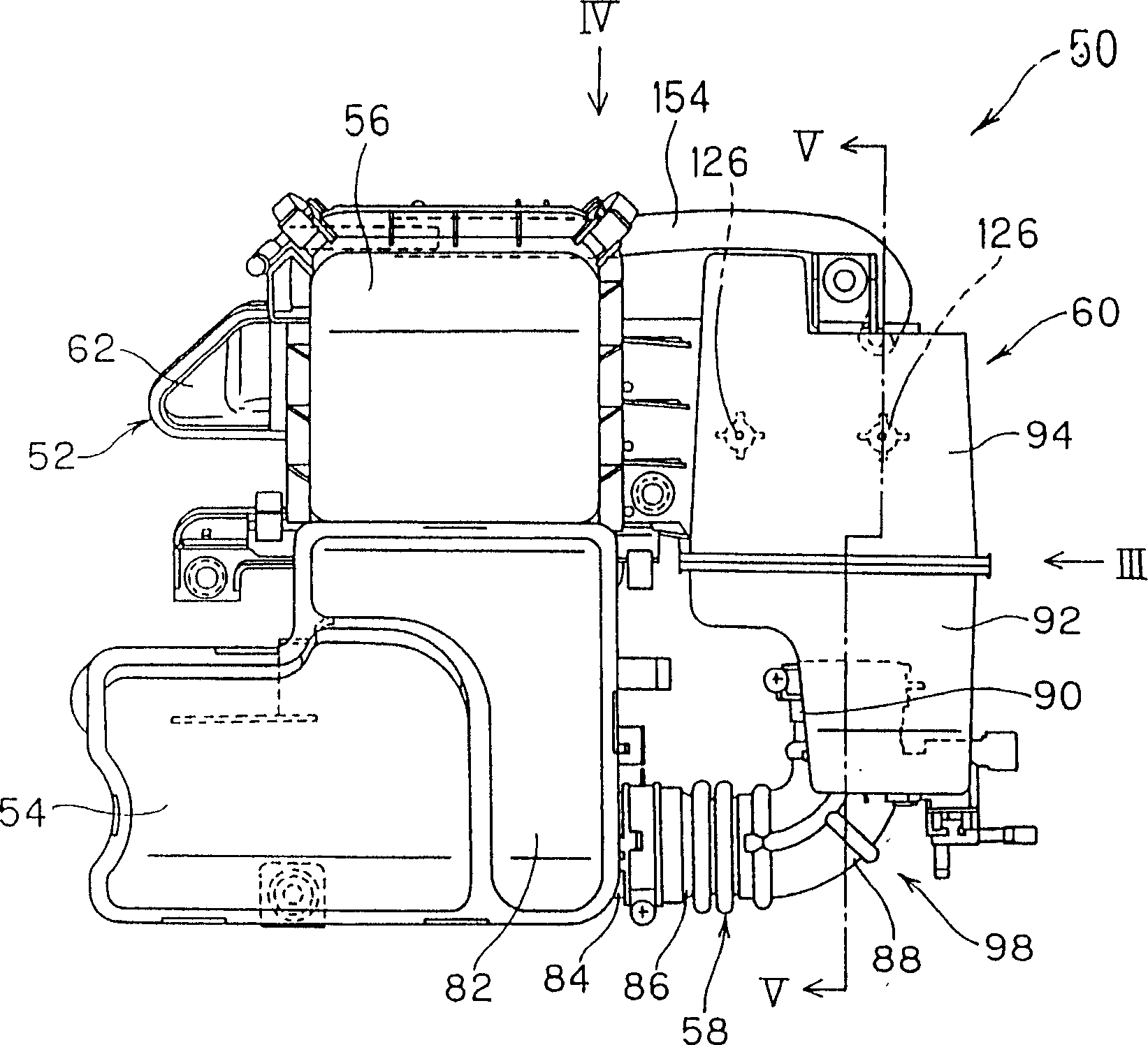

[0022] Example 1: Figure 1-Figure 8 Shows the first embodiment of the present invention. exist Figure 6-Figure 8 In the engine room (not shown) of the vehicle, a multi-cylinder (3-cylinder) engine 2 installed side by side is located at the lower part of the engine 2 and is connected to a gearbox 4 installed on the left side of the engine 2 . The engine 2 and the transmission 4 are mounted on the vehicle in the longitudinal direction of the crankshaft, that is, in the lateral direction X of the vehicle (the left-right direction of the vehicle).

[0023] The engine 2 is provided with a lower cylinder block 6 , an upper cylinder head 8 , an oil pan 10 attached to the lower portion of the cylinder block 6 , and a cylinder head 12 attached to the upper portion of the cylinder head 8 .

[0024] On the cylinder block 6, a water pump 16 and an alternator 18 are installed on the right side of the vehicle while being supported by the crankshaft 14 in the lateral direction X of the v...

Embodiment 2

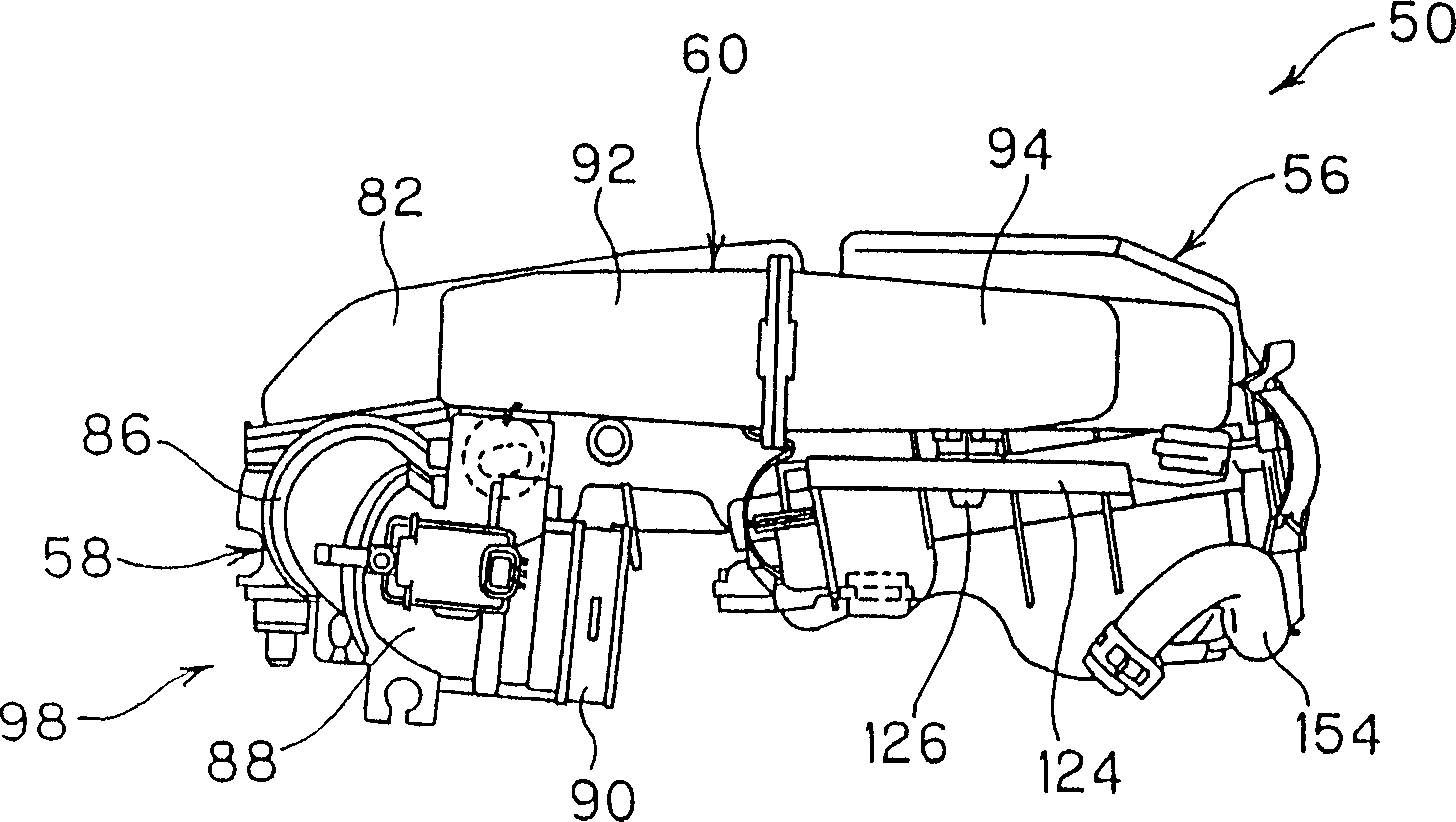

[0068] Example 2: Figure 9 It is a special structure of the present invention and shows the second embodiment.

[0069] In this second embodiment, parts having the same functions as those in the above-mentioned first embodiment are denoted and described with the same symbols.

[0070] The characteristic points of this second embodiment are as follows. That is, the downstream side resonator 60 is composed of a front box 92 and a rear box 94, and the required capacity is set, and the front box 92 and the rear box 94 can slide relative to each other, for example, the rear box 94 can This rear case 94 is fixed at a predetermined position by a fixing means (not shown) by sliding with respect to the front case 92 .

[0071] According to this second embodiment, for example, the design status of the vehicle, such as in the case of a low chassis or a high chassis, the rear side box 94 is slid so that the downstream side resonator 60 can be adapted to the capacity required for the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com