Measuring method of curved surface

A measurement method and surface technology, applied in measurement devices, instruments, etc., can solve the problems of too much redundant data and slow measurement speed, and achieve the effect of reducing redundant data, improving efficiency, and obvious data topology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

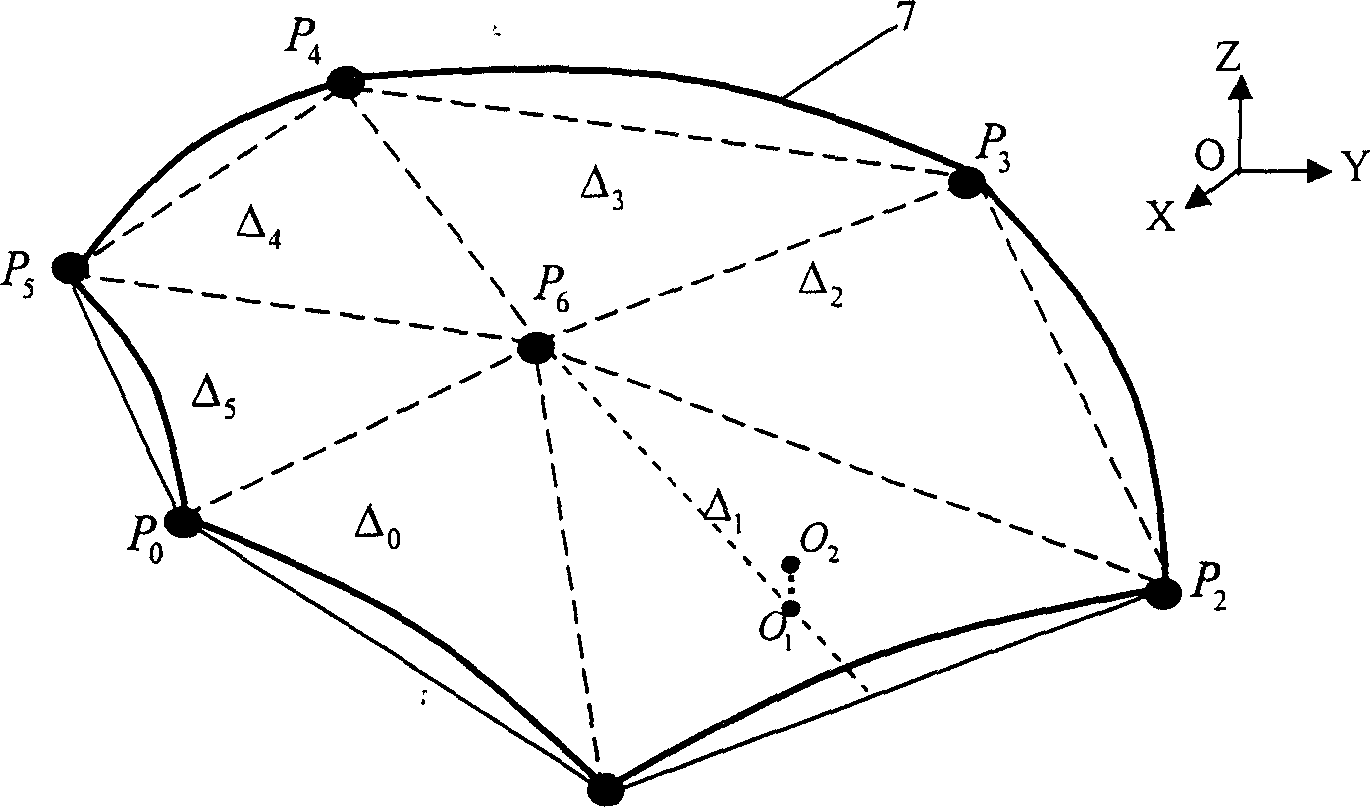

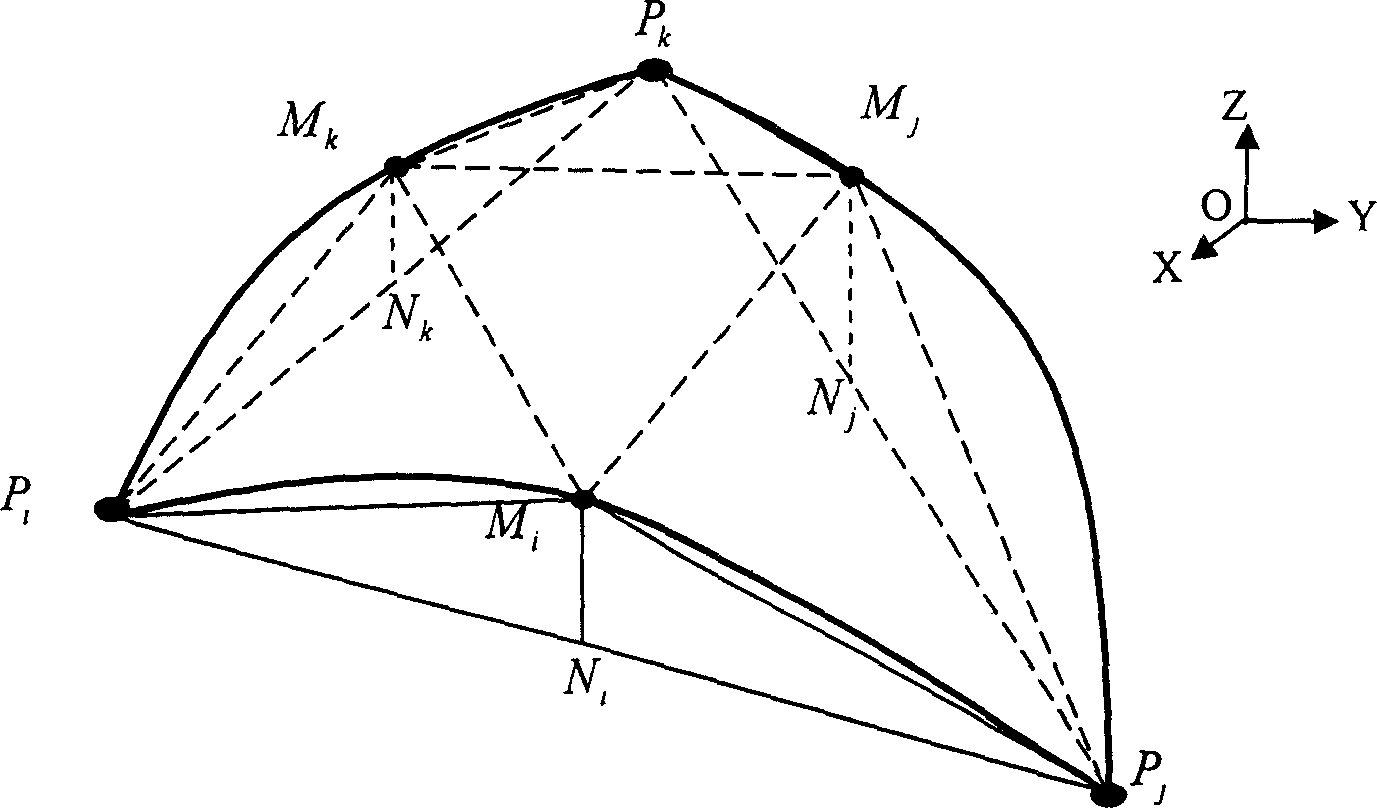

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

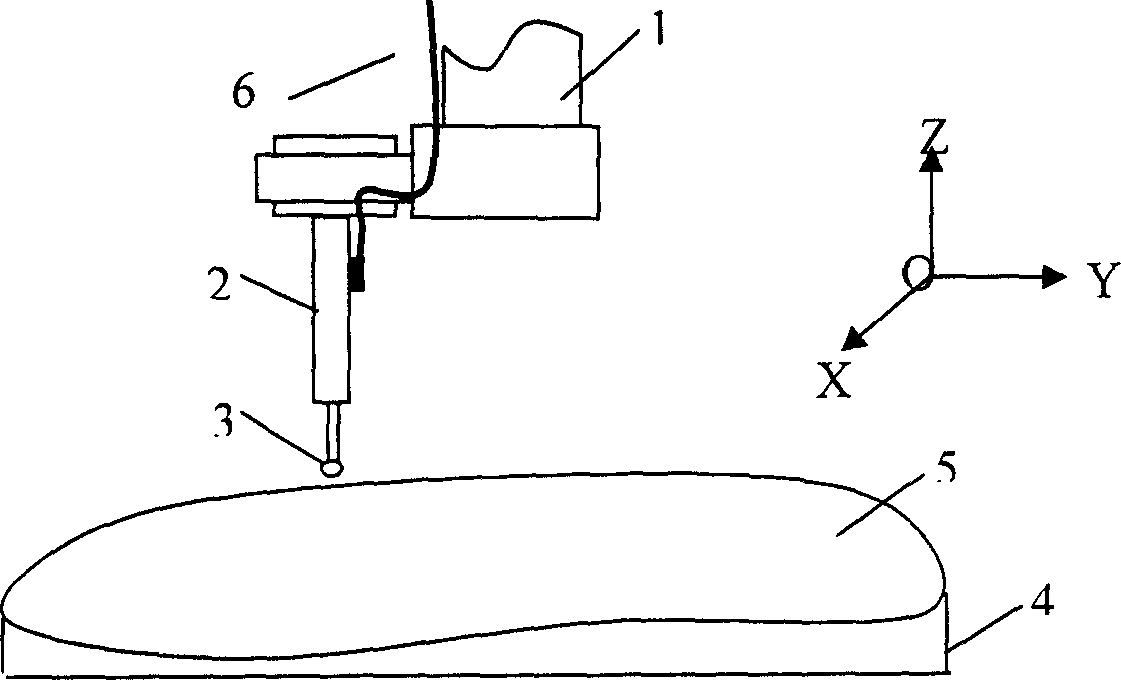

[0021] The curved surface measuring method of the present invention can be realized by a contact measuring system. The contact measurement system may use a frame robot system in the prior art, or other measurement systems well known to those skilled in the art. figure 1 A schematic structural diagram of a tactile measurement system is given as an example. As shown in the figure, a tactile measurement system generally includes a frame 1, a measuring rod 2, and a probe 3. The measurement system can drive the probe 3 to move to the workpiece according to the program instructions. At a certain measurement point on the surface 5 of 4, the position data of the measurement point is measured by the trigger signal generated by the contact between the probe 3 and the surface 5, and the measurement data is returned to the computer in the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com