Bootstrap type connecting terminal

A terminal and crimping ring technology, which is applied in the field of transmission lines, can solve problems such as difficulties for electricians, hidden dangers of safe production and transmission in the electrical industry, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

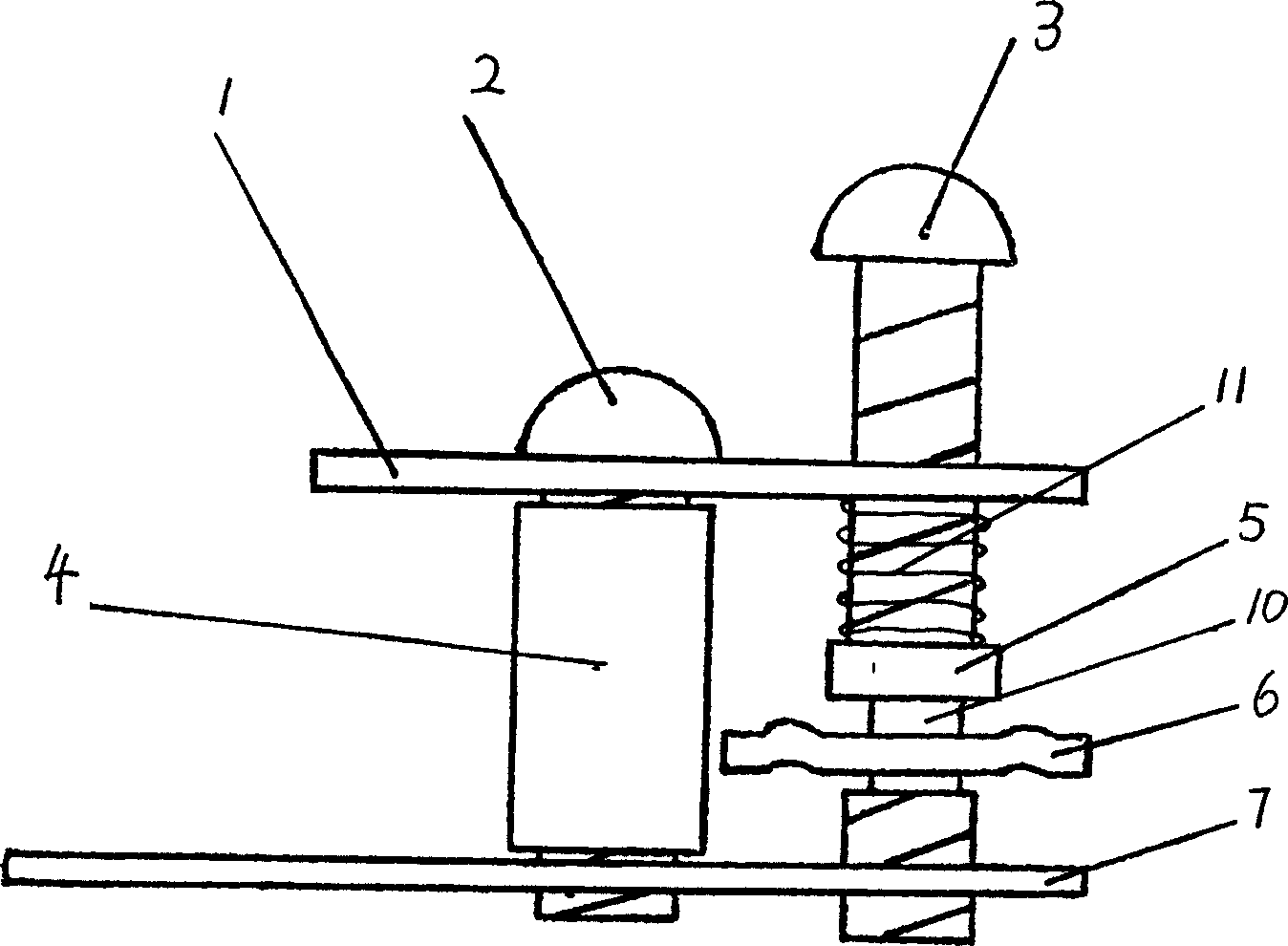

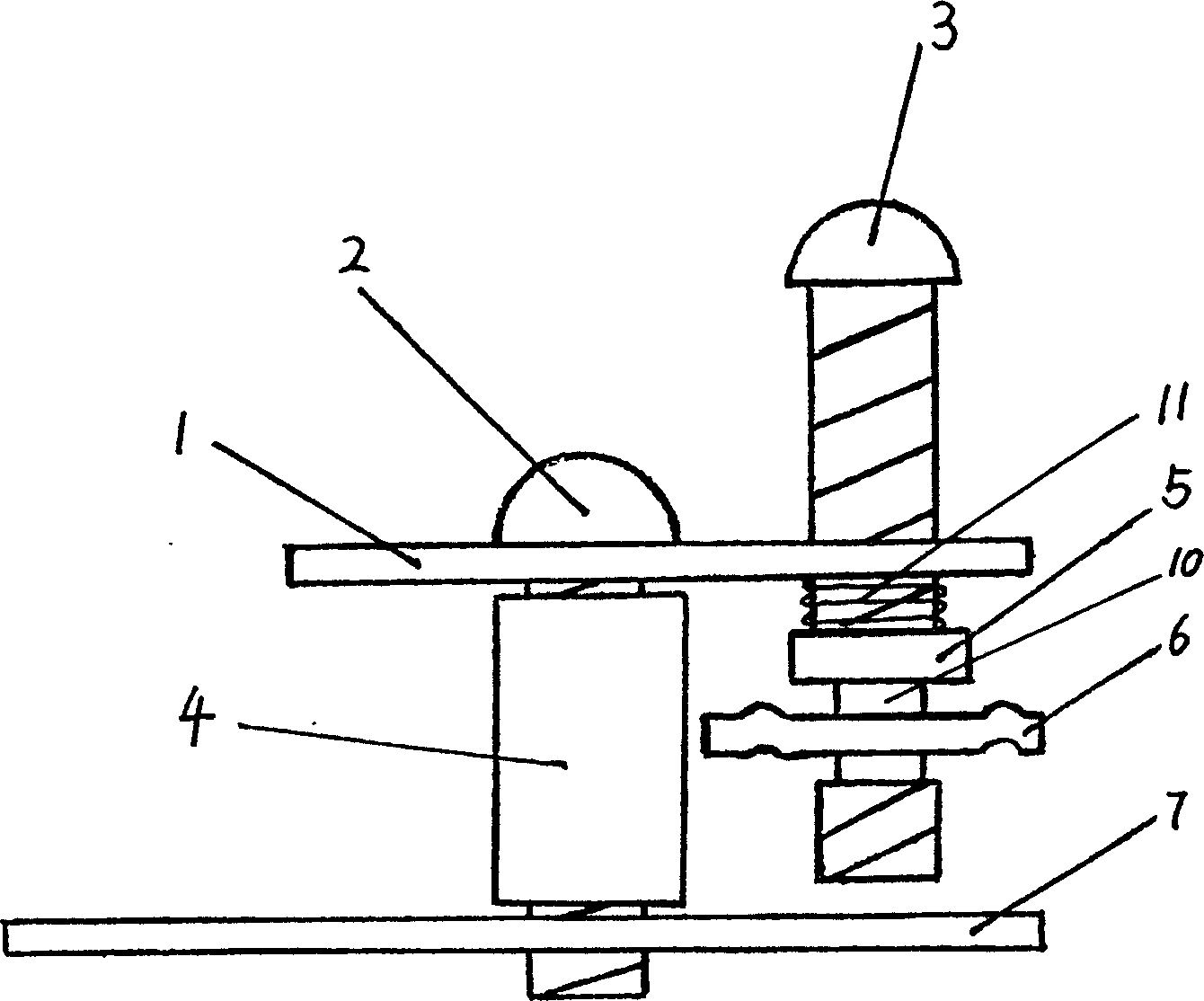

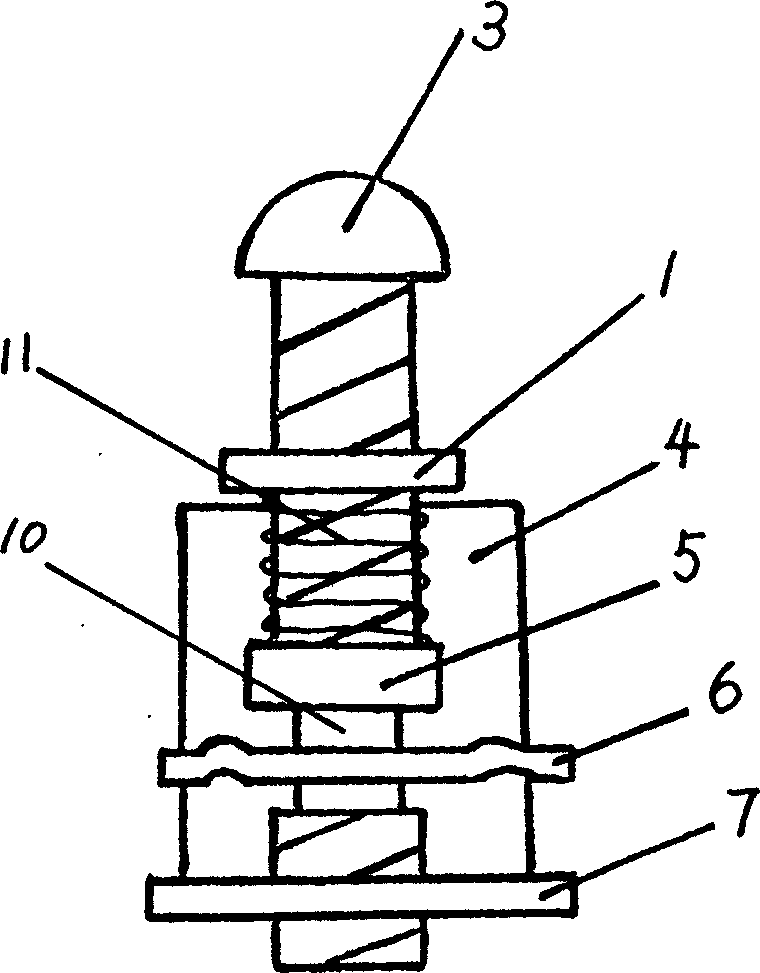

[0009] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0010] by figure 1 Given, the structure of the present invention is that the lower part of the support piece 1 is equipped with a support block 4 through the upper screw 2 and the threaded head of the lower end of the support block 4 is screwed into the screw hole 8 on the terminal panel 7, next to the support block 4. A combination bolt 3 is screwed between the support sheet 1 and the terminal panel 7. The combination bolt 3 has a smooth body 10 at the lower part (that is, this part is not threaded), and the upper part of the smooth body 10 is screwed together with the combination bolt 3 The crimping ring 5 is equipped with a crimping gasket 6 on the smooth body 10 at the lower part of the crimping ring 5, and the screw head at the lower part of the smooth body is screwed into the screw hole 9 on the terminal panel 7; in order to ensure the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com