Automatic cleaning apparatus for disc type celatom filter

A diatomite filter and automatic cleaning technology, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of troublesome cleaning, affecting environmental sanitation, increasing cleaning work intensity, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

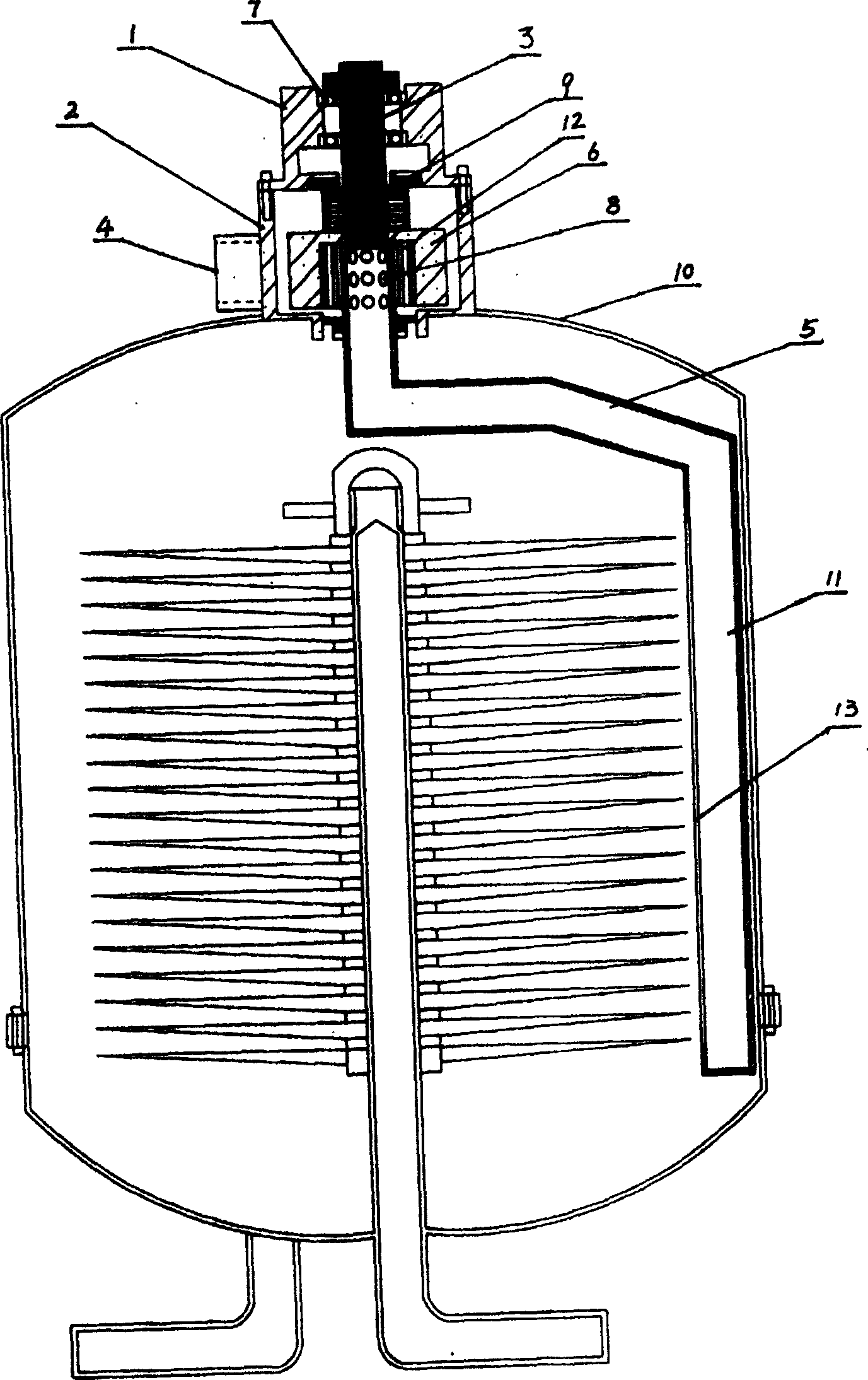

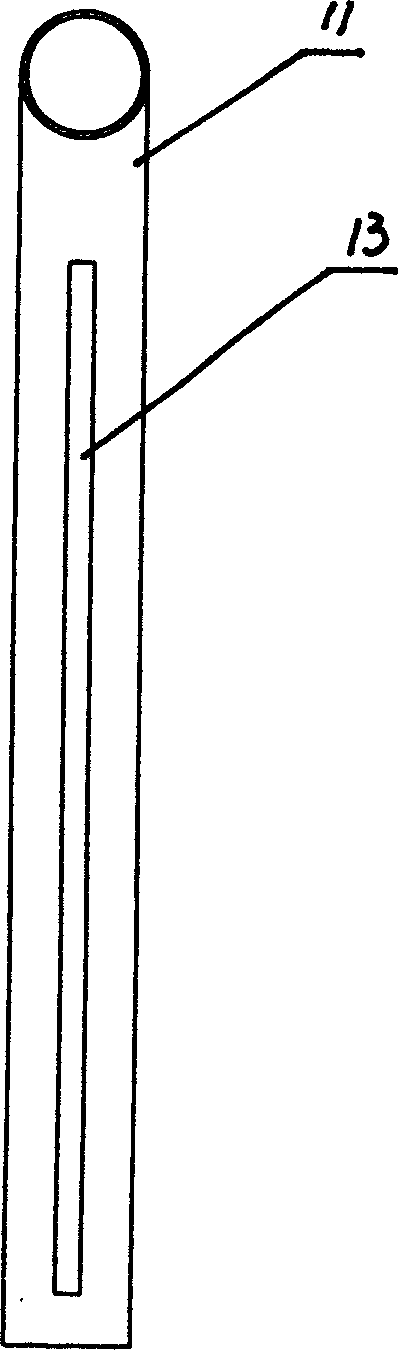

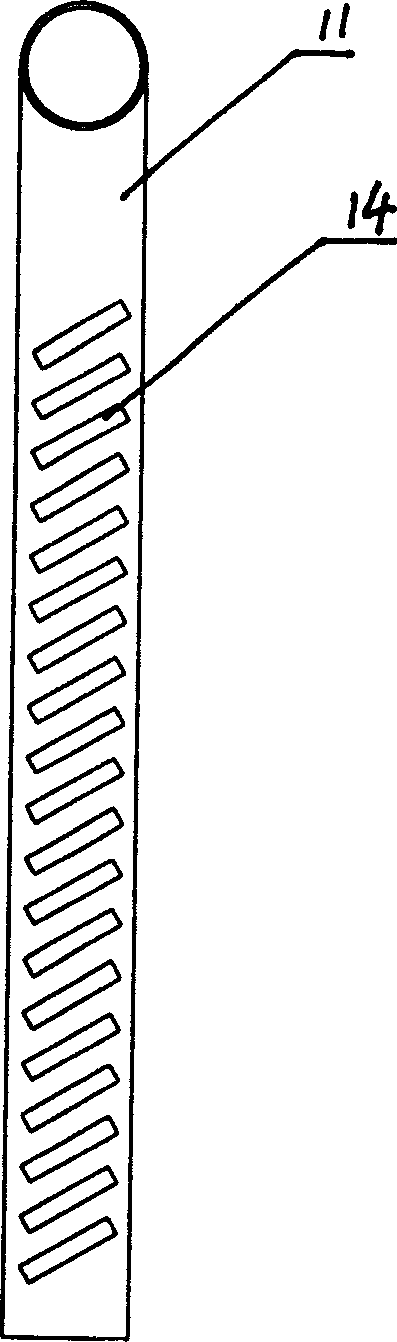

[0012] Such as figure 1 , figure 2 , image 3 Shown, a kind of automatic cleaning device of disc type diatomite filter, it comprises upper machine cover 1, lower machine cover 2, central shaft 3, water inlet 4 and water spray gun 5, upper machine cover 1 and lower machine The cover 2 is connected by bolts to form a water supply chamber 6, and a rotatable central shaft 3 is provided in the axial direction of the water supply chamber 6. The upper end of the central shaft 3 is solid, protruding from the water supply chamber 6, and the central shaft 3 is fixed on the shaft through the bearing. On the bearing position 7 of the upper machine cover 1, the lower end of the central shaft 3 stretches out of the water supply chamber 6 to connect with the water spray gun 5, and the central shaft 3 is provided with small holes 8 on the pipe wall in the water supply chamber 6. A mechanical seal ring 9 is provided at the joint between the cover 1 and the lower machine cover 2, and a mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com