LED lighting lamp and its manufacturing method

A technology of LED lighting and manufacturing method, which is applied in the field of lighting, can solve problems such as powerlessness and LED damage, and achieve the effects of saving man-hours, sufficient contact, and reduced selection conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

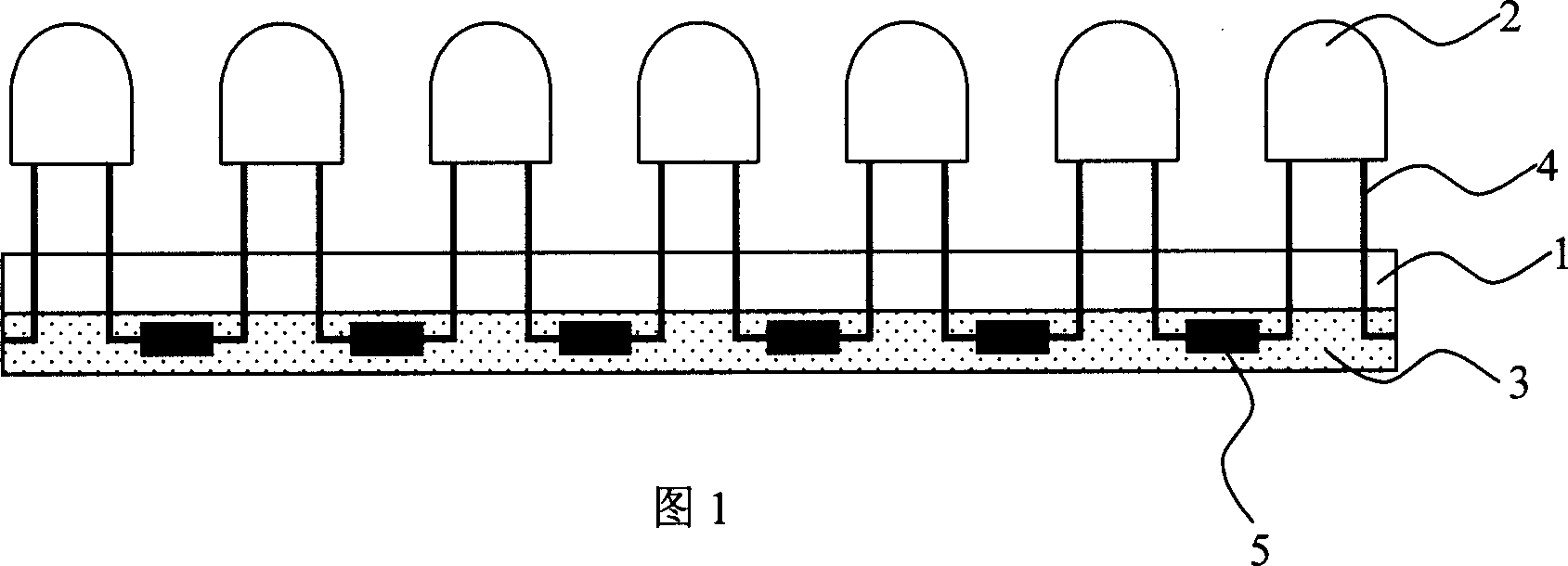

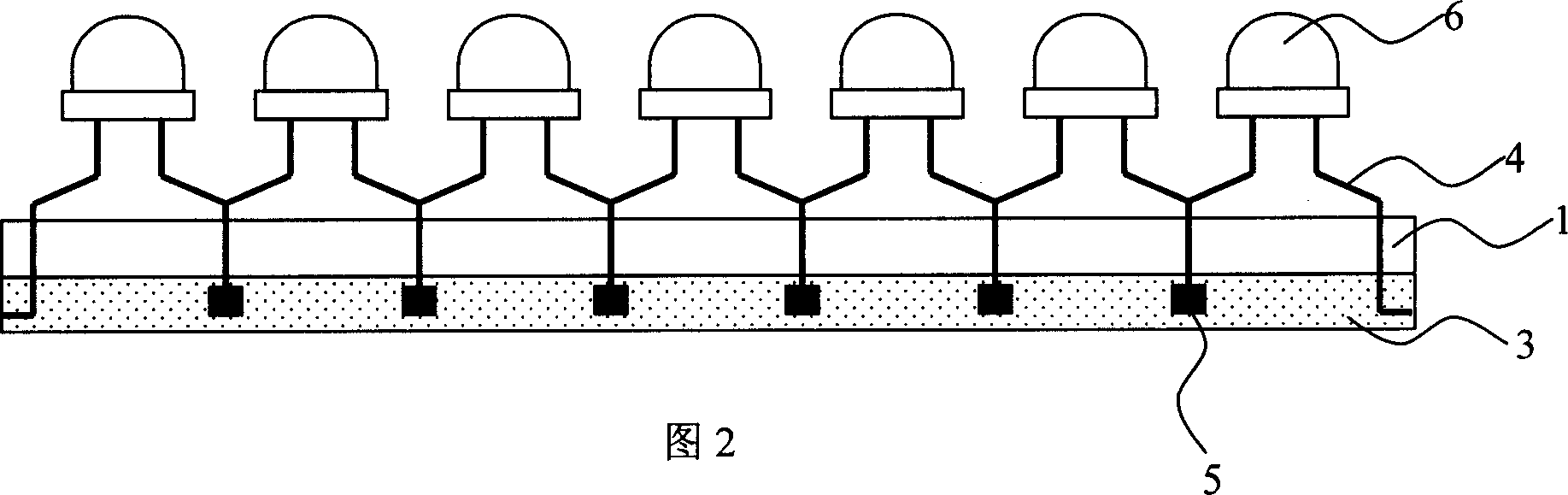

[0019] The invention provides an LED lighting fixture, which uses several LED lamps as light sources. The pins of these LED lamps pass through an insulating substrate and are connected to each other on the back of the insulating substrate according to a predetermined circuit structure. The LED lamps used in the present invention can be 2-pin LEDs such as various cylindrical, conical, and straw hat-shaped LEDs, or piranha LEDs, and multi-pin special-shaped LEDs. Based on the above structure, theoretically speaking, there is no special requirement for the insulating substrate, and any solid insulating material can be used, such as glass plate, PCB board, plastic plate, etc. In the present invention, ceramic plates with low price and good insulating effect are preferred, especially It is currently the most popular ultra-thin ceramic plate for research and development. Its material is thin (up to about 3mm), high strength, light weight, smooth and delicate surface, which is conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com