Wound-rotor type transformer and power source utilizing wound-rotor type transformer

A power supply device and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, electric light source, lighting device, etc., can solve the problems of increasing insulation distance and insufficient safety, and achieve the effect of improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

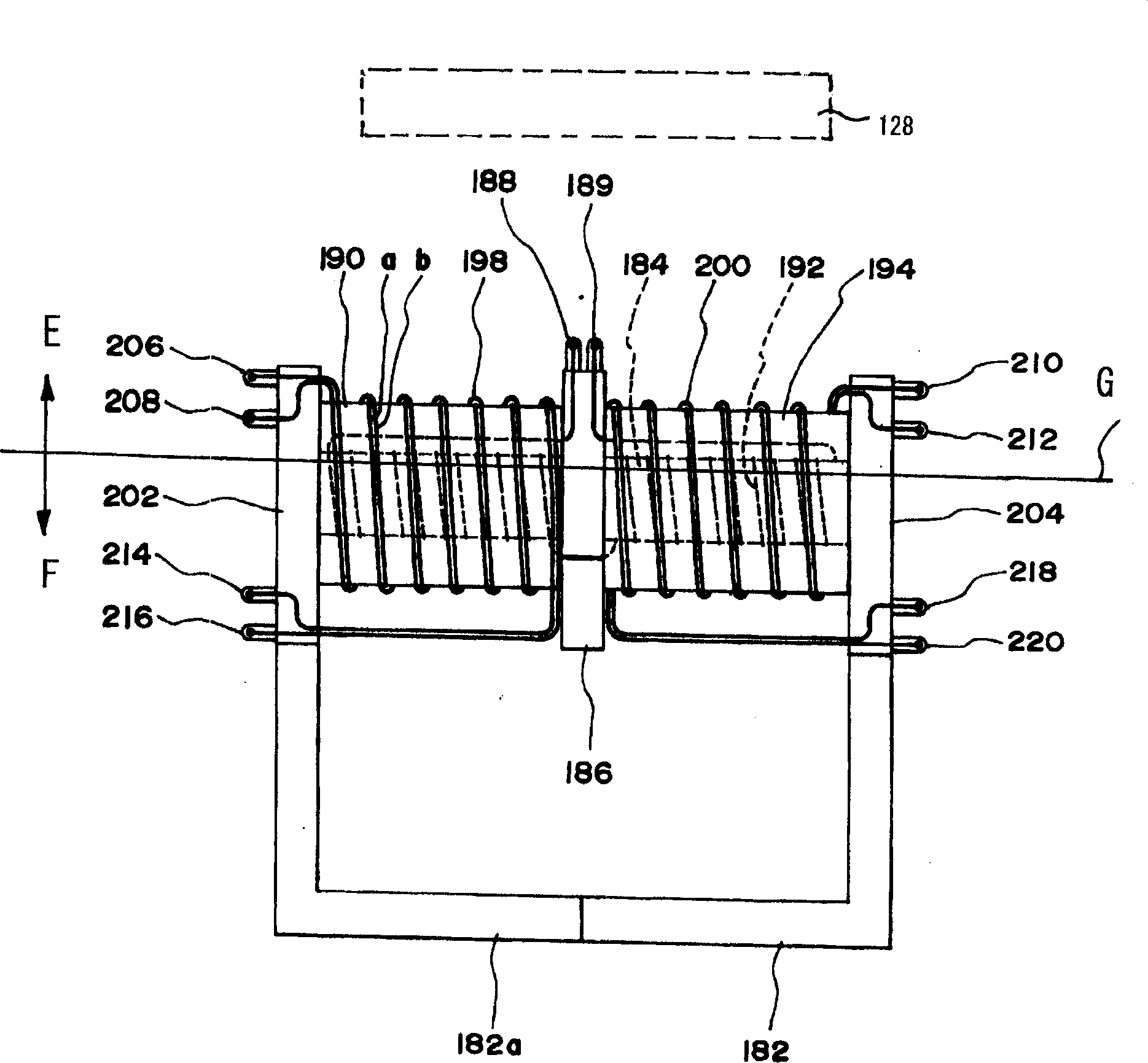

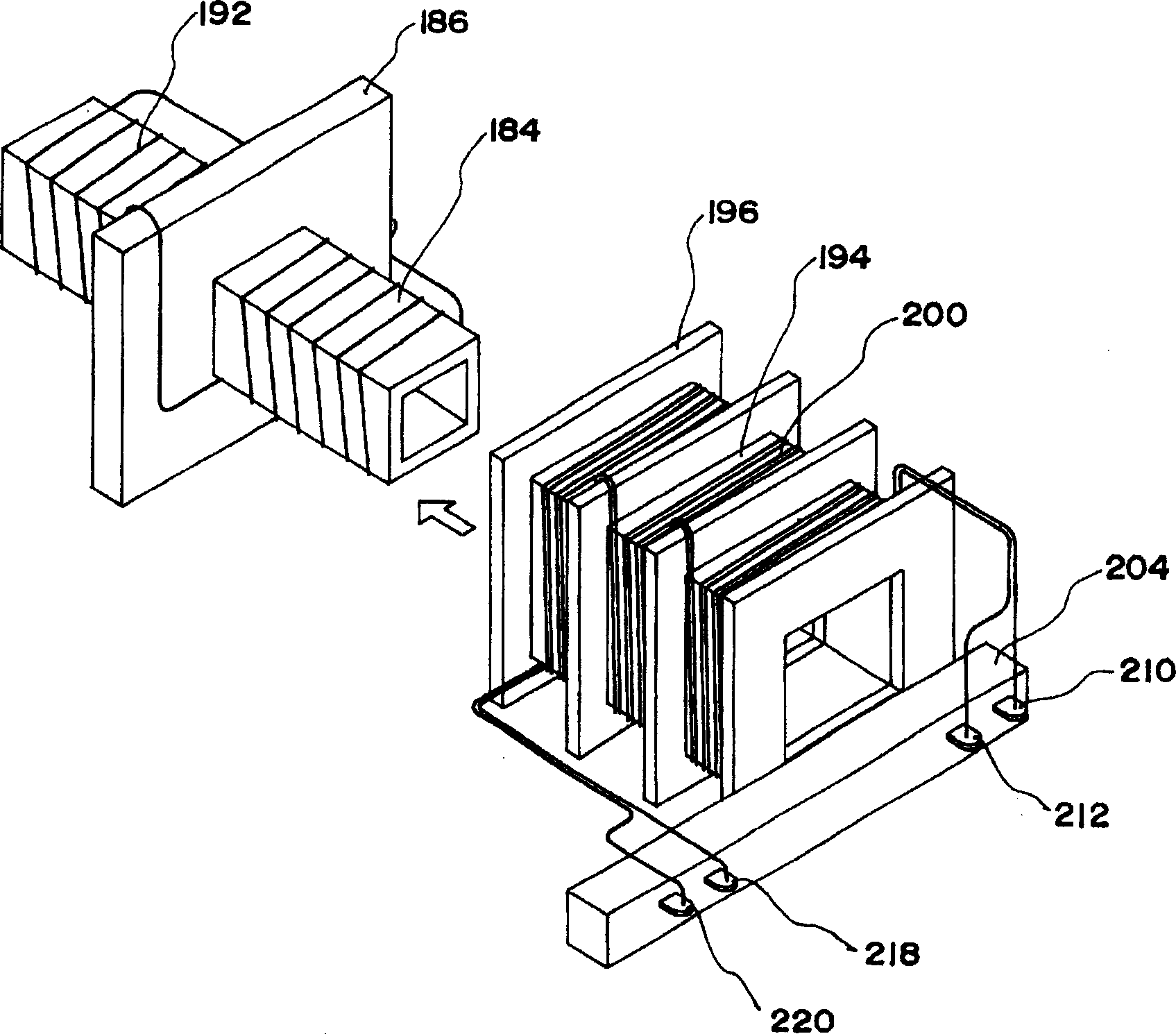

[0107] In Fig. 1, 182 is an iron core, and two iron cores in [shape and] shape are joined to form a quadrangular frame-shaped iron core. The primary bobbin 184 is inserted into one of the parallel portions of the iron core 182 . The terminal base 186 is fixed at the center of the primary bobbin 184 , and the primary output terminals 188 and 190 are set on the terminal base 186 . The primary winding 192 is mounted on the aforementioned bobbin 184, and both ends of the primary winding 192 are connected to the primary output terminals 188 and 190 via lead wires.

[0108] A pair of secondary bobbins 191 and 194 are inserted and arranged on the outside of the aforementioned primary bobbin 184 and on both sides of the terminal block 186 . The partitions 196 at each end of the secondary bobbins 191 and 194 are in contact with both side surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com