Start-up circuit and method for controlling permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and starting circuit, applied in the direction of starting device, etc., can solve the problems of high manufacturing cost, large harmonic interference, complex control algorithm, etc., and achieve the effect of reducing the cost of motor driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

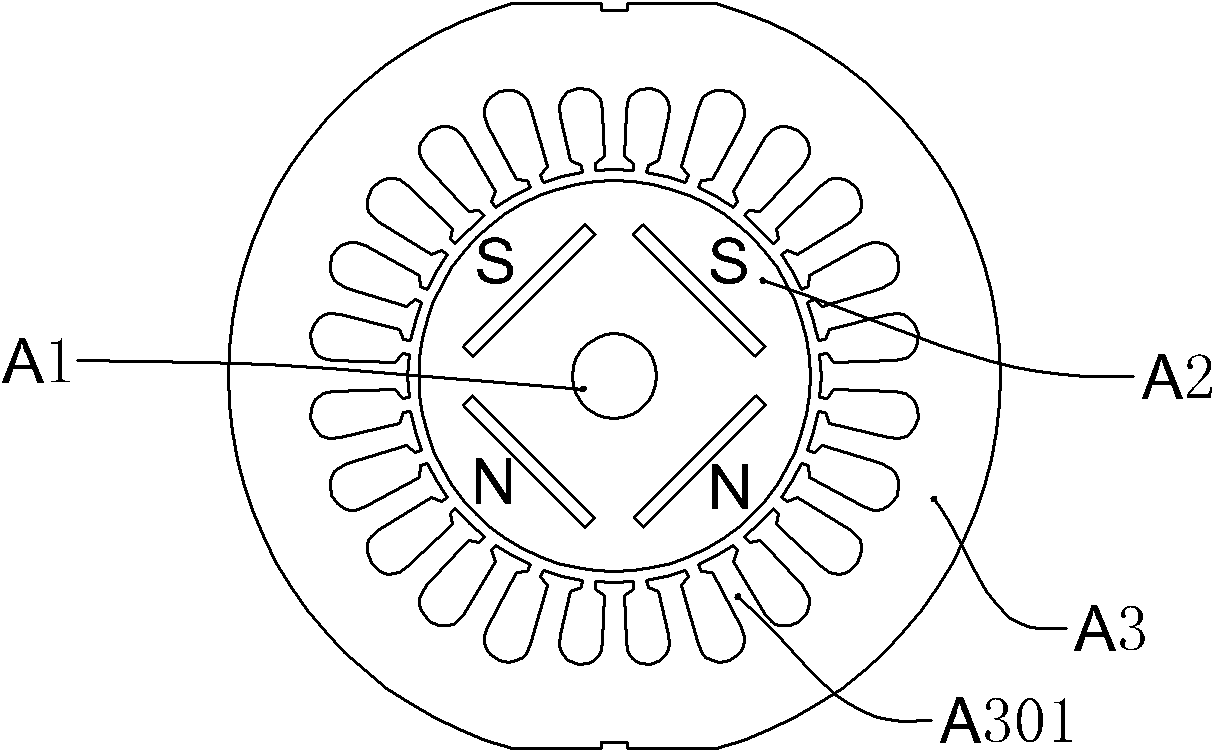

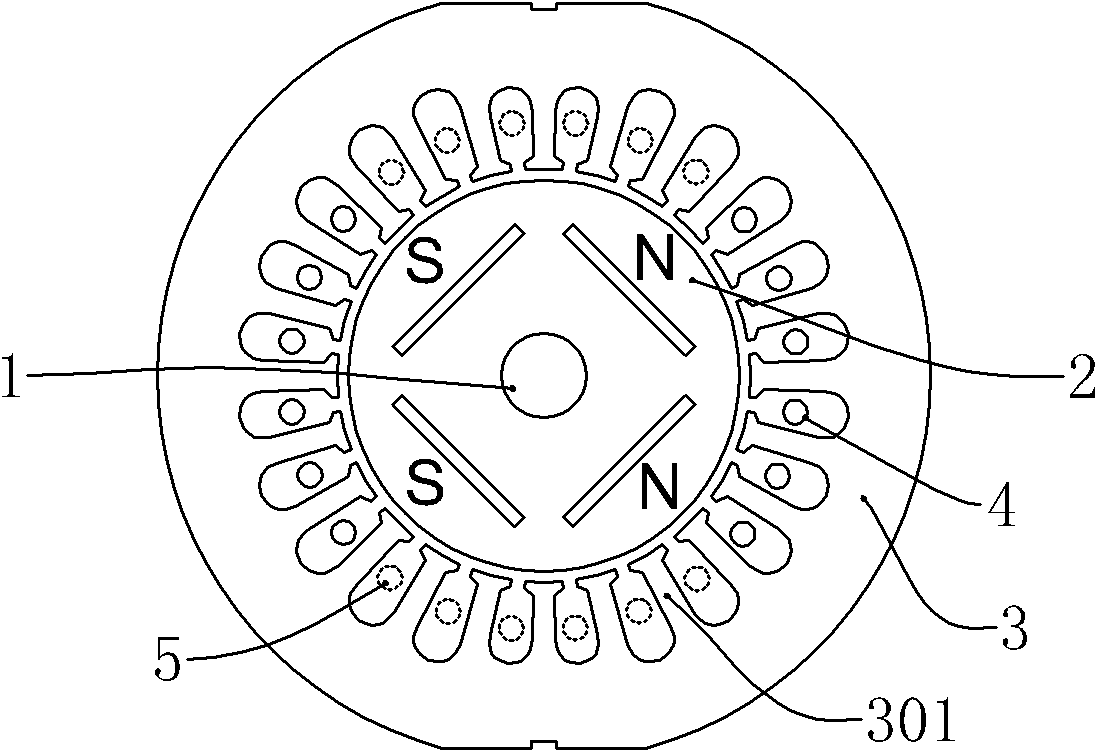

[0026] like figure 2 As shown, a single-phase permanent magnet synchronous motor includes a rotating shaft 1, a rotor 2, and a stator 3. The rotor 2 is sleeved on the rotating shaft 1, and the stator 3 is sleeved on the outside of the rotor 2; the rotor is a permanent magnet pole, and its There are two adjacently arranged S magnetic poles and two adjacently arranged N magnetic poles, and the two S magnetic poles are symmetrically distributed with the two N magnetic poles. Of course, three adjacently arranged S magnetic poles can also be arranged symmetrically. and three adjacently arranged N magnetic poles; the stator 3 is an inner-toothed salient pole core, with twenty-four salient pole core teeth 301; wherein, the main winding 4 and the auxiliary winding 5 have a spatial difference of 90 It is wound on the salient pole core teeth 301 of the stator in a degree manner.

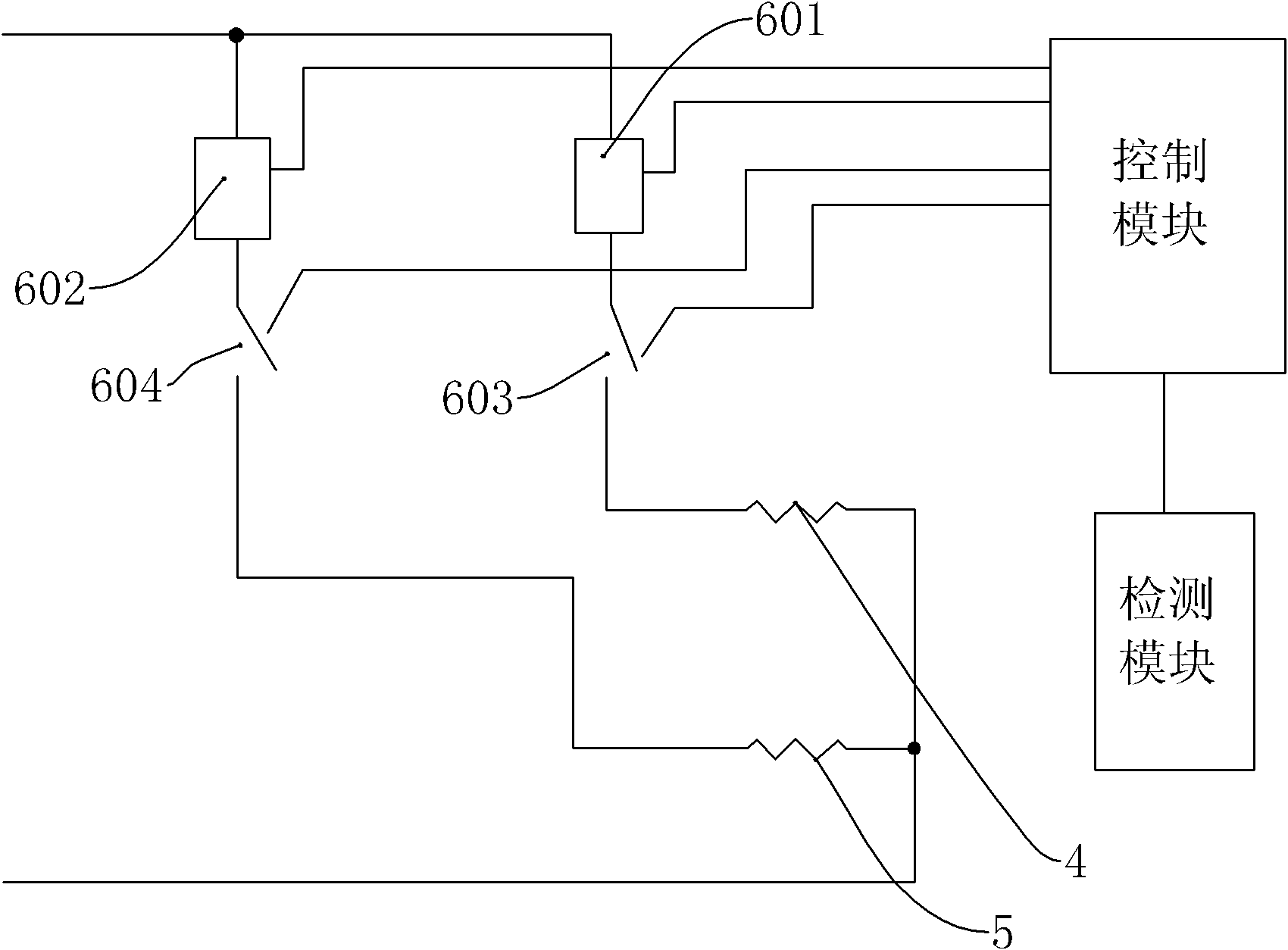

[0027] like image 3 As shown, a starting circuit for controlling the above-mentioned single-phase perma...

Embodiment 2

[0039] The difference from Embodiment 1 is that the permanent magnet synchronous motor is a three-phase permanent magnet synchronous motor, and the difference between the three-phase permanent magnet synchronous motor and the single-phase permanent magnet synchronous motor is that the number of windings of the rotor and the synchronous working power supply are different; Figure 8 As shown, a three-phase permanent magnet synchronous motor includes three windings: winding A, winding B and winding C, and winding A, winding B and winding C are wound in such a way that two adjacent windings differ in space by 60 degrees On the salient pole core teeth 301 of the stator 3 .

[0040] like Figure 9 As shown, a starting circuit for controlling the above-mentioned three-phase permanent magnet synchronous motor, the starting circuit includes an electronic switch A1 for converting alternating current into intermittent positive current or intermittent negative current, and an electronic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com