Heat collection and water storage equipment self-locking installed from vacuum heat collection glass diversion pipes with size changed of using solar energy

A technology of solar glass and vacuum heat collecting tubes, applied in the field of solar energy applications, can solve problems such as difficult fixation, easy water leakage, system paralysis, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

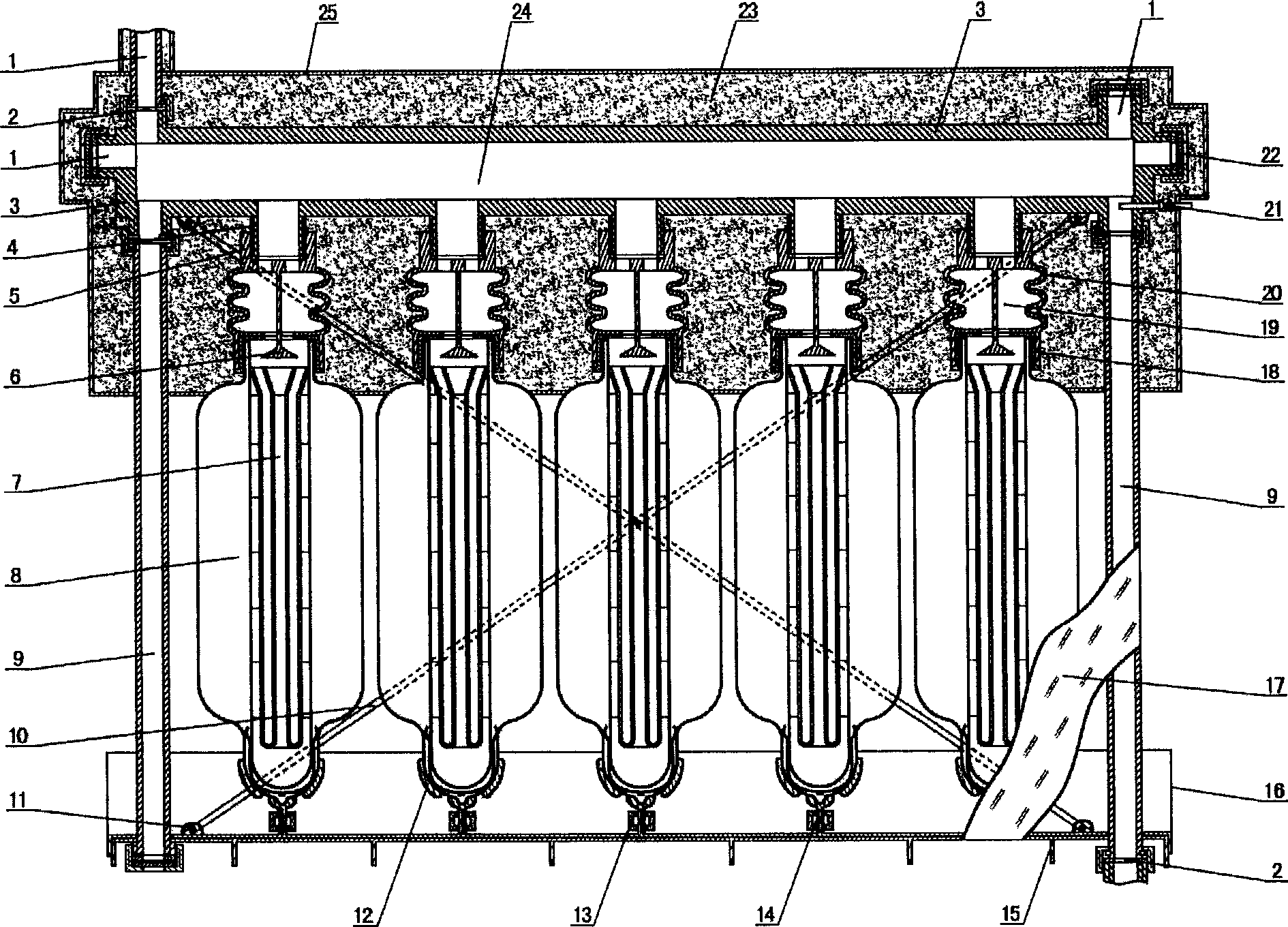

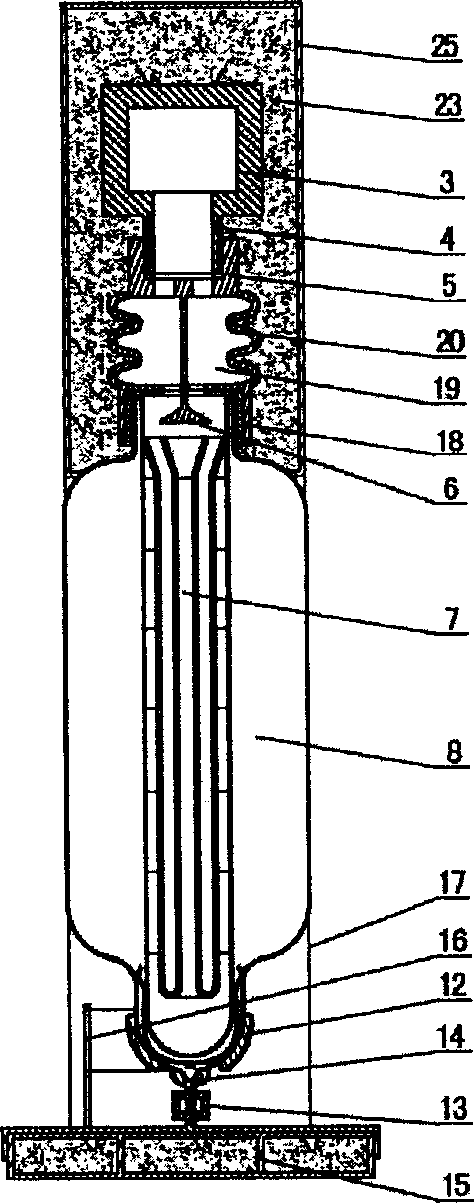

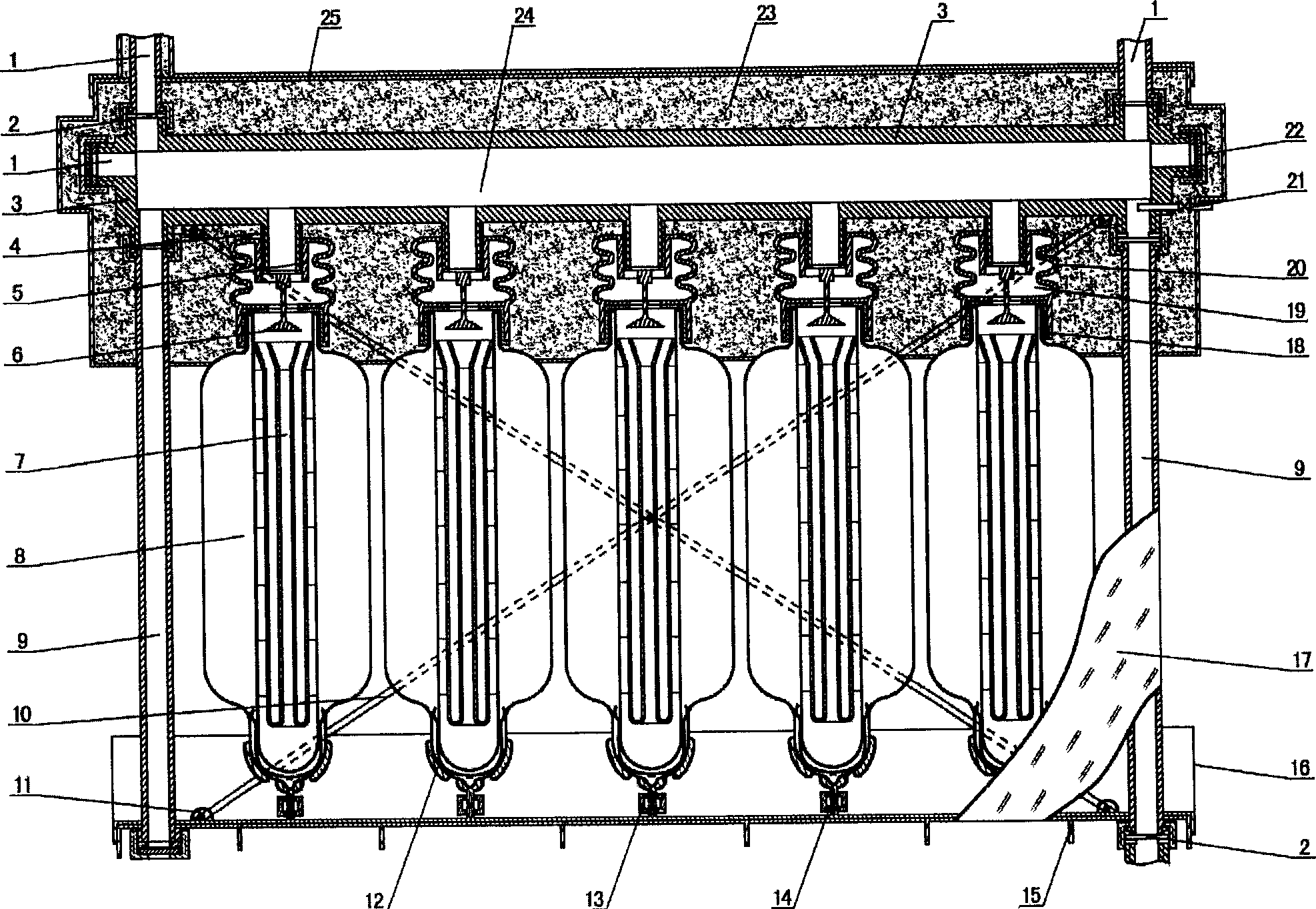

[0045] figure 1 , figure 2 It is the first embodiment, in the figure: the single-pass solar glass variable-diameter vacuum heat collecting tube 8 that is arranged with the tubular antifreeze deflector 7 is fixed on the circulating tubular fluid pipe 3 and the water inlet and outlet frame pipes by the tightening bolt 13 and the positioning bolt 14. 9. Bracket 15, bracket rib plate 16, frame rib 10, and frame rib connection point 11 are connected to the heat collecting module, and are fixed on the lumen pipe joint 4, and the elastic normally closed valve is connected to the pipe fitting 5 by sealing installation 1, bellows wall 20 composed of flexible pipe fittings, the single-pass solar glass variable-diameter vacuum heat-collecting tube 8 installed with the tubular antifreeze deflector 7 is sealed, installed and fixed on the frame to form a single-pass variable-diameter flow-guiding solar heat collection module. The thermal insulation material 23, the heat collecting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com