Semi permeable type liquid crystal display, and producing method

A technology of liquid crystal display and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, static indicators, instruments, etc., can solve the problems of lower reflectivity, lower transmittance, darker display color, etc., to improve contrast and brightness, and improve reflection. The effect of high rate, high black and white display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

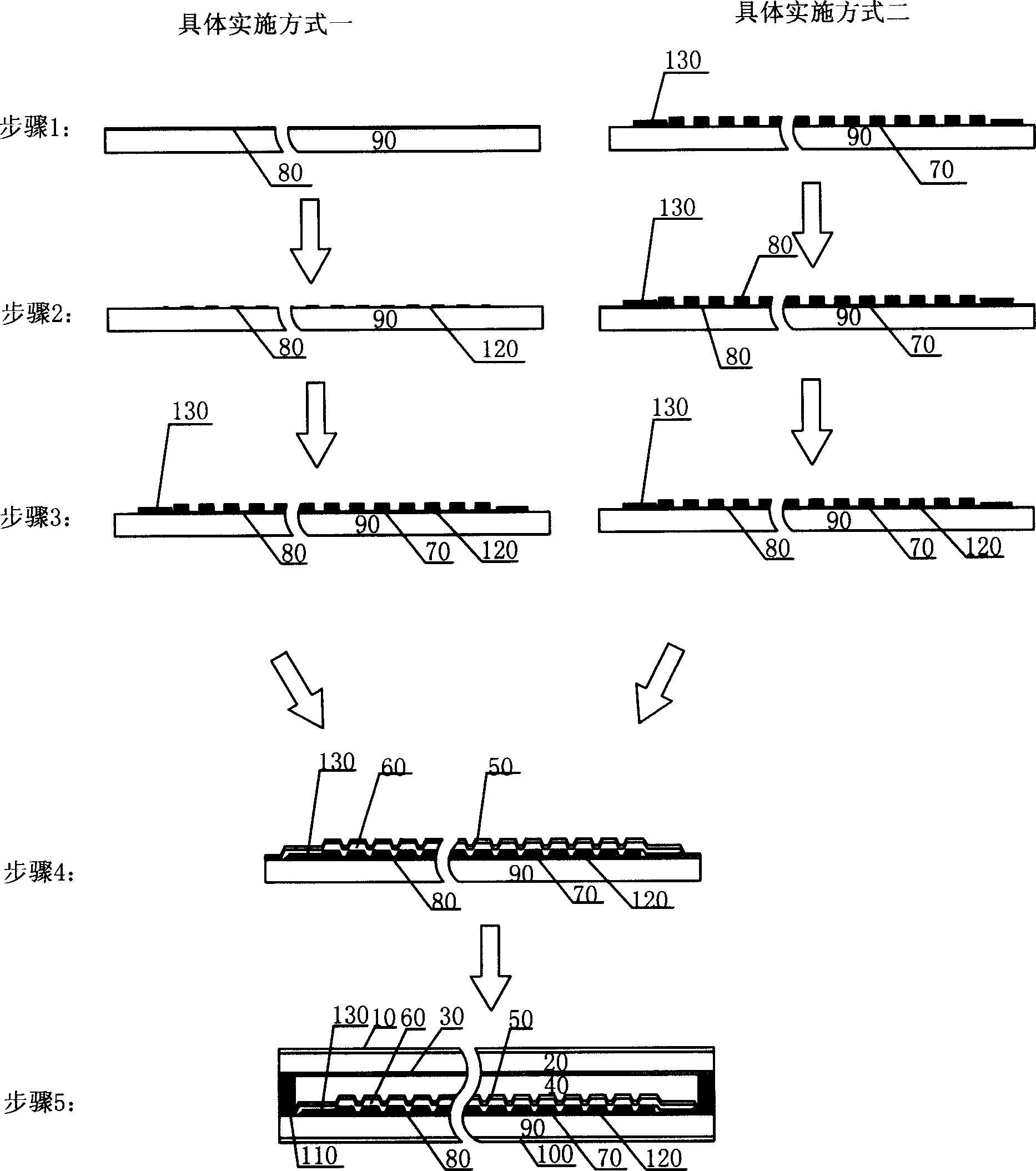

specific Embodiment approach 1

[0038] This semi-transmissive liquid crystal display includes an upper polarizer 10, an upper transparent substrate 20, an upper transparent conductive film 30, a liquid crystal 40, and a lower transparent conductive film 50 in sequence from the external light source to the backlight source, and sequentially from the backlight source to the external light source. Including a lower polarizer 100 and a lower transparent substrate 90, on the lower transparent substrate 90 are sequentially a reflective film 80 with an opening 120, a color filter film 70, an insulating layer 60 covering the color filter film 70 and coated with a lower transparent conductive film 50 . At each opening 120 of the reflective film 80 , the color filter film 70 partially covers the reflective film opening 120 , and the area of the color filter film 70 is smaller than the area of the reflective film opening 120 .

[0039] The reflective film 80 is an aluminum film.

[0040] The colors represented by ...

specific Embodiment approach 2

[0050]This semi-transmissive liquid crystal display includes an upper polarizer 10, an upper transparent substrate 20, an upper transparent conductive film 30, a liquid crystal 40, and a lower transparent conductive film 50 in sequence from the external light source to the backlight source, and sequentially from the backlight source to the external light source. Including a lower polarizer 100 and a lower transparent substrate 90, on the lower transparent substrate 90 are a color filter film 70, a reflective film 80 with an opening 120, covering the color filter film 70 and the reflective film 80 and coated with a lower transparent conductive film 50 The insulating layer 60.

[0051] At each opening 120 of the reflective film, the color filter film 70 partially covers the reflective film opening 120 , and the area of the color filter film 70 is smaller than the area of the reflective film opening 120 .

[0052] The reflective film 80 is a silver film.

[0053] The colors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com