Semiconductor device and method for manufacturing the same

A technology of semiconductor and opening position, applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of energy loss, quality factor value reduction, etc., and achieve the effect of reduced energy loss, high Q value, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

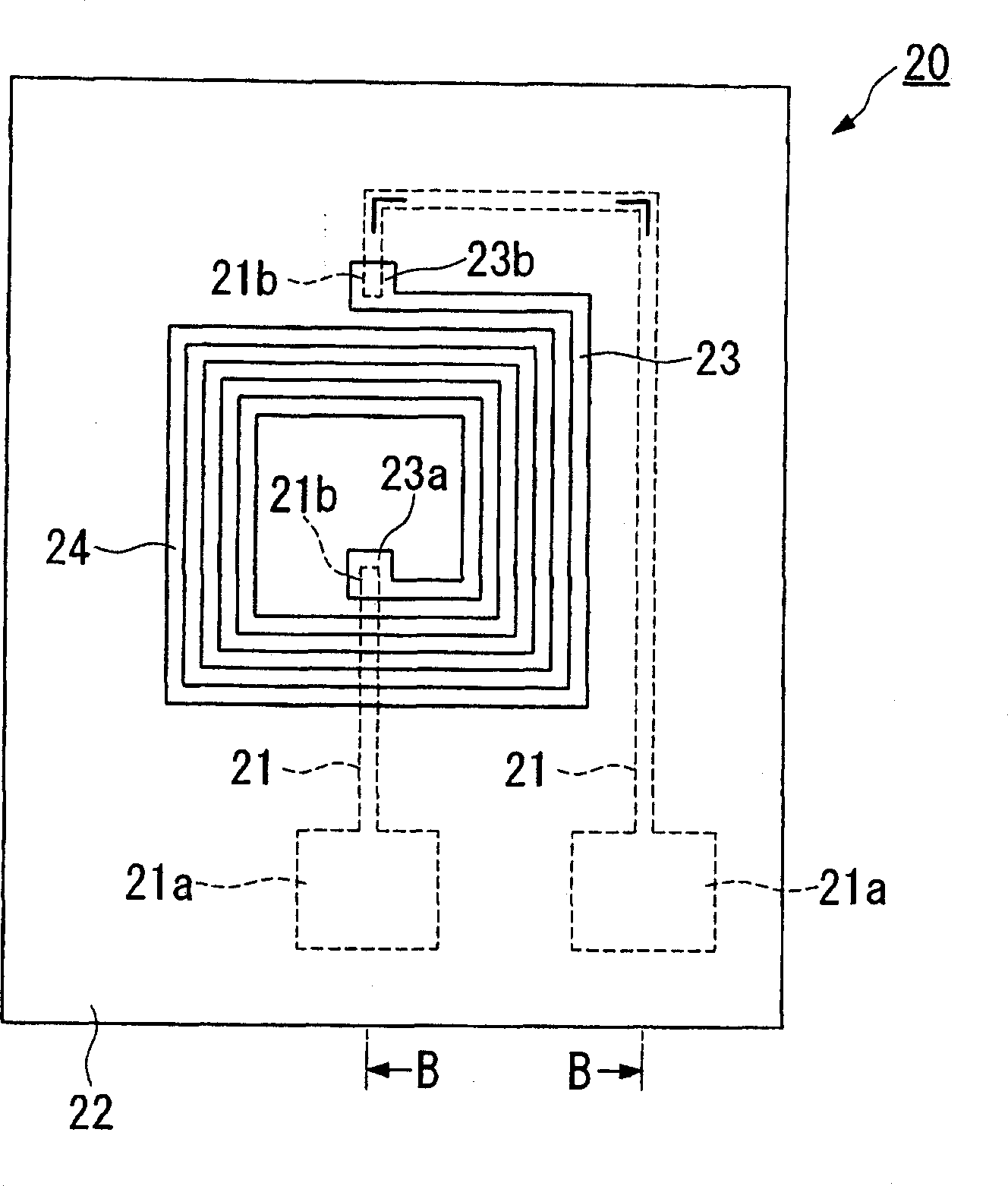

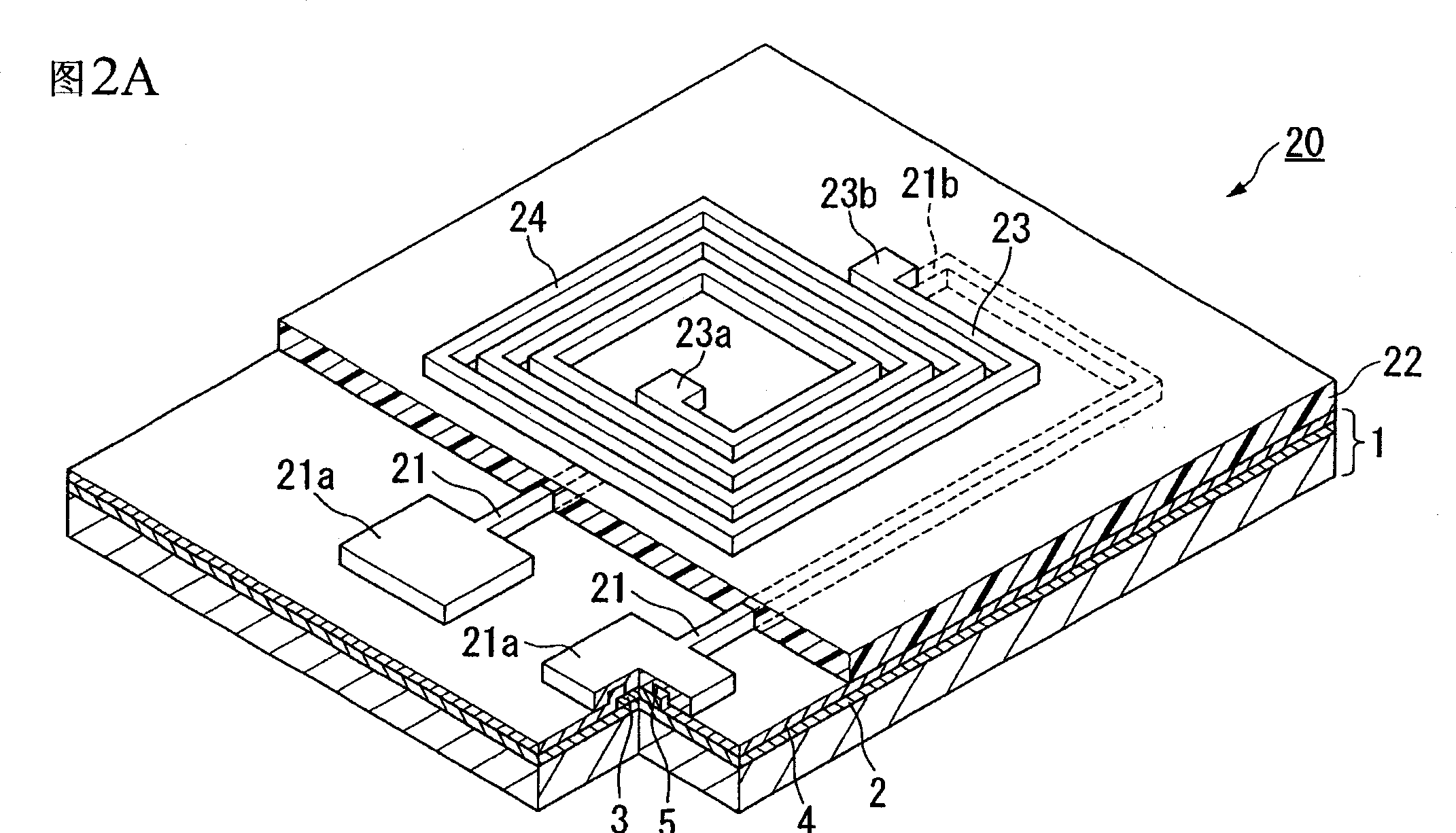

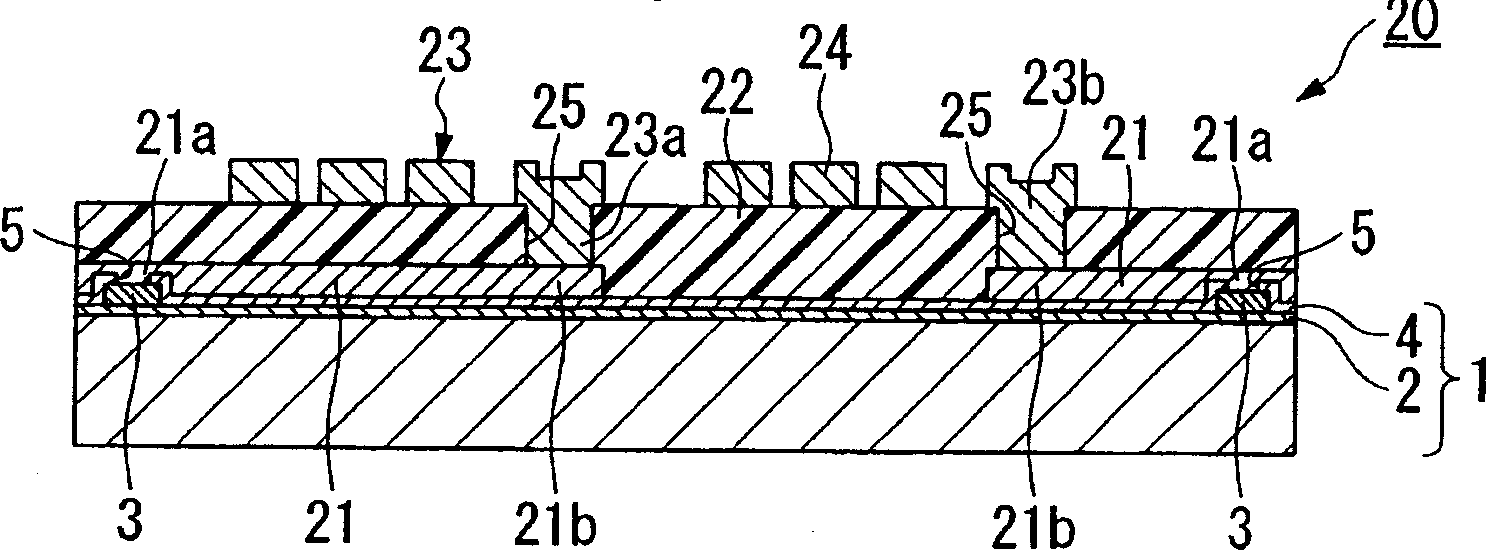

[0113] Manufacture of semiconductor devices and evaluation of their characteristics. A silicon substrate is used as the semiconductor substrate. The first insulating resin layer and the second insulating resin layer are formed of polyimide resin. A first wiring layer is provided between the first insulating resin layer and the second insulating resin layer, and a second wiring layer is provided on the second insulating resin layer. The dielectric element was formed as a 3.5-turn helical coil. Copper (Cu) is used as the material of the first wiring layer and the second wiring layer.

[0114] Location of the sensing element

[0115] As a working example of the present invention, a semiconductor device having a first wiring layer near the semiconductor substrate as an interconnection (lower path) and a second wiring layer away from the semiconductor substrate as a dielectric element was fabricated . As a comparative example, a semiconductor device having a first wiring layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com