Nanometer degradable insulation package membrane and its production method

A manufacturing method and packaging film technology, applied in the directions of packaging, wrapping paper, manufacturing tools, etc., to achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

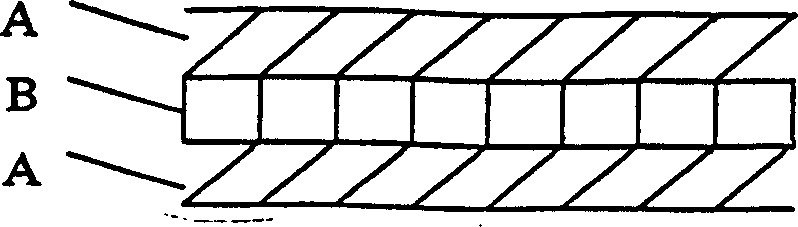

[0058] In an embodiment of the present invention, the packaging film and bag have a three-layer structure of PO / nano PPC or nano-PVA / PO.

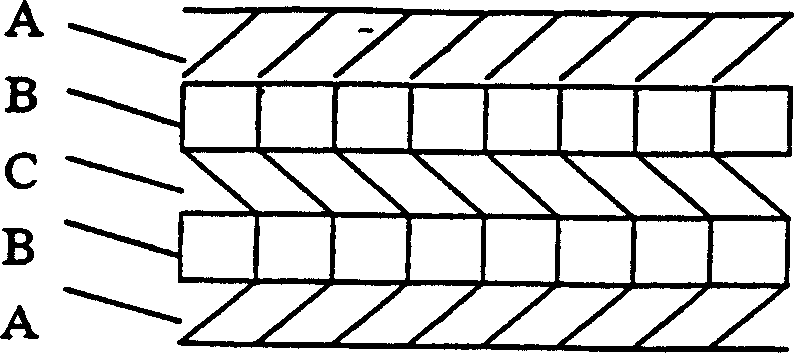

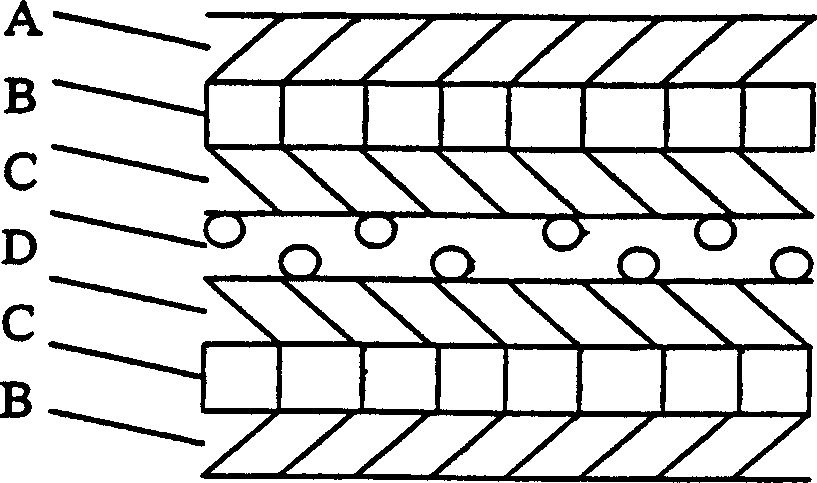

[0059] In another embodiment of the present invention, the food packaging film or bag is at least one of PO / nano-modified PPC, (PCL) or (APC) or a combination thereof / PVA / PPC, PCL or APC At least one or a combination / POD five-layer structure. The thickness of various embodiments is 5-50um / 10-100um / 5-50um5-30um / 5-30um / 10-50um / 5-30um / 5-30um.

[0060] See the attached picture,

[0061] figure 1 The structure of is a PO / nano PPC or nano PVA / PO three-layer structure, where the A layer is PO, and the B layer is one or a combination of nano PPC and nano PVA.

[0062] figure 2 At least one of PO / nano-modified PPC, (PCL) or (APC) or a combination / at least one of PVA / PPC, PCL or APC or a combination / POD five-layer structure, wherein the A layer is PO , Layer B is at least one of nano-modified PPC, (PCL) or (APC) or a combination thereof.

[0063] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com