Large-scale structure integral hositing device and method

A technology of overall lifting and large structure, applied in the direction of lifting device, hoisting device, etc., can solve the problems of high price of self-locking feed-through jack, random deviation of the structure, unacceptable to the owner, etc., and it is easy to guarantee the safety. , easy to promote, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The lifting object is a large roof structure with a weight of 100t.

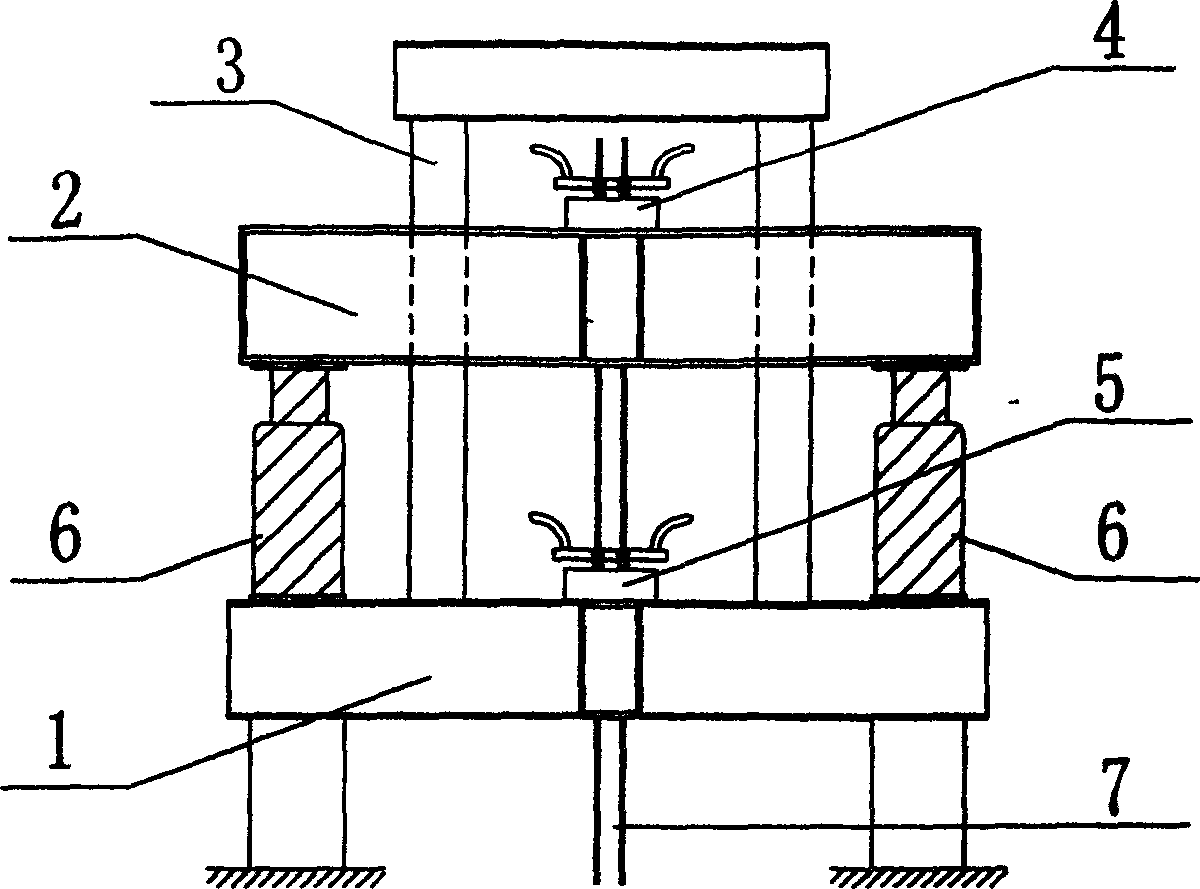

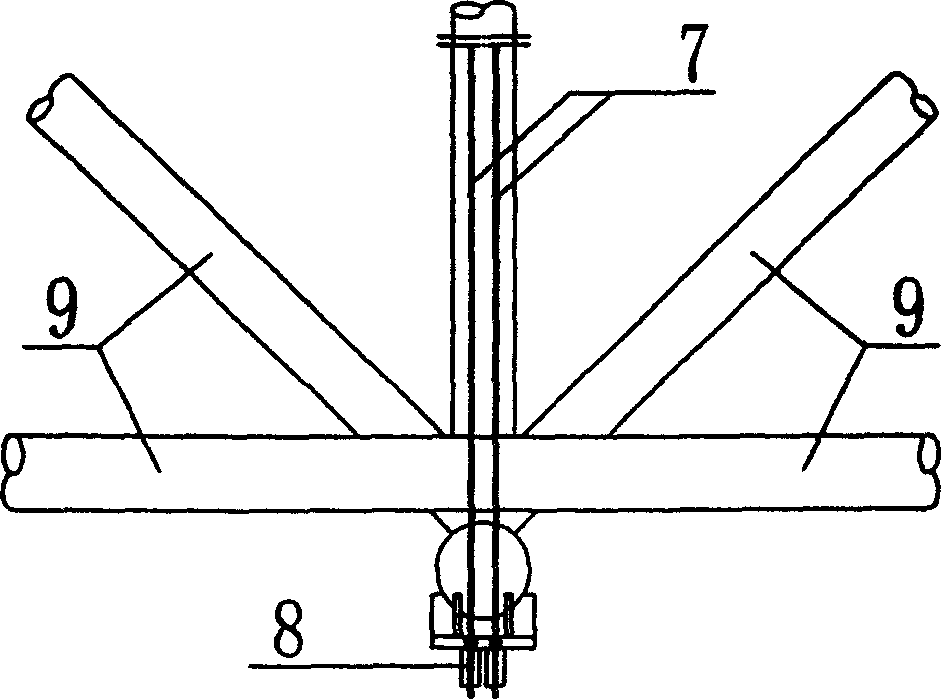

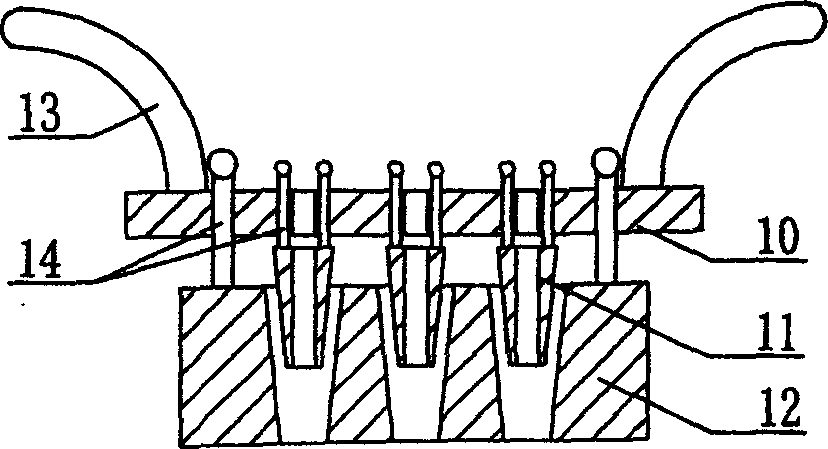

[0034] Such as figure 1 , 2 As shown, the lifting device used in this embodiment includes a fixed beam 1, a movable beam 2, a lifting jack 6, a guide rail 3, an upper tool anchor 4, a lower tool anchor 5, a steel hinge line 7 and a working anchor 8. Among them, the steel hinge line 7 is fixed on the roof structure 9 through the working anchor 8, and passes through the lower tool anchor 5 and the upper tool anchor 4 in sequence; the lower tool anchor 5 is installed in the middle of the fixed beam, and the upper tool anchor 4 is installed in the movable beam In the middle, two lifting jacks 6 are installed between the two inner ends of the fixed beam and the movable beam; the fixed beam 1 is installed on the supporting structure, the guide rail 3 is located on both sides of the steel hinge line 7, and the lower end is fixed on the fixed beam 1, passing through Active beam 2.

[0035] Before lifting, ...

Embodiment 2

[0037] The lifting object is a large roof structure with a weight of 200t, and the lifting device and method used are the same as in Embodiment 1.

Embodiment 1 and Embodiment 2

[0038] Embodiment 1 and Embodiment 2 Raise the cost situation:

[0039] On the two levels of lifting the roof structure weights of 100t and 200t, the implementation costs of Embodiment 1 and Embodiment 2 relative to the traditional overall lifting method using large self-locking through-hole jacks are shown in Table 1. It can be seen from comparison that the implementation cost is very low by adopting the integral lifting device of the present invention.

[0040]

[0041] The price unit in the table is: RMB Yuan

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com