Cutting knife angle-adjusting method

A technology for adjusting angles and cutting knives, applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of time-consuming adjustment, error-prone, and affecting the production capacity of line-drawing mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the technical content of the present invention, a preferred specific embodiment is given as follows.

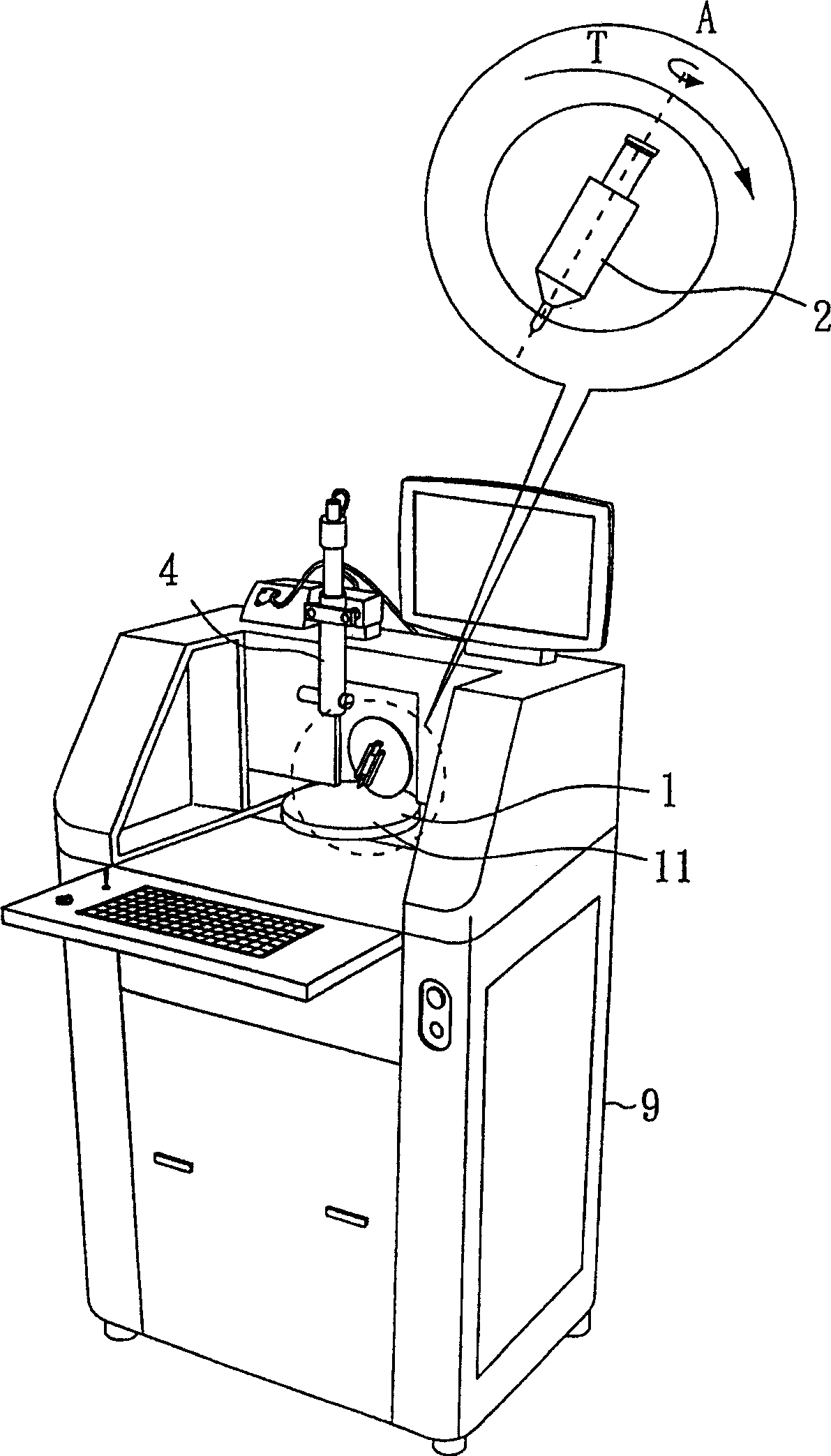

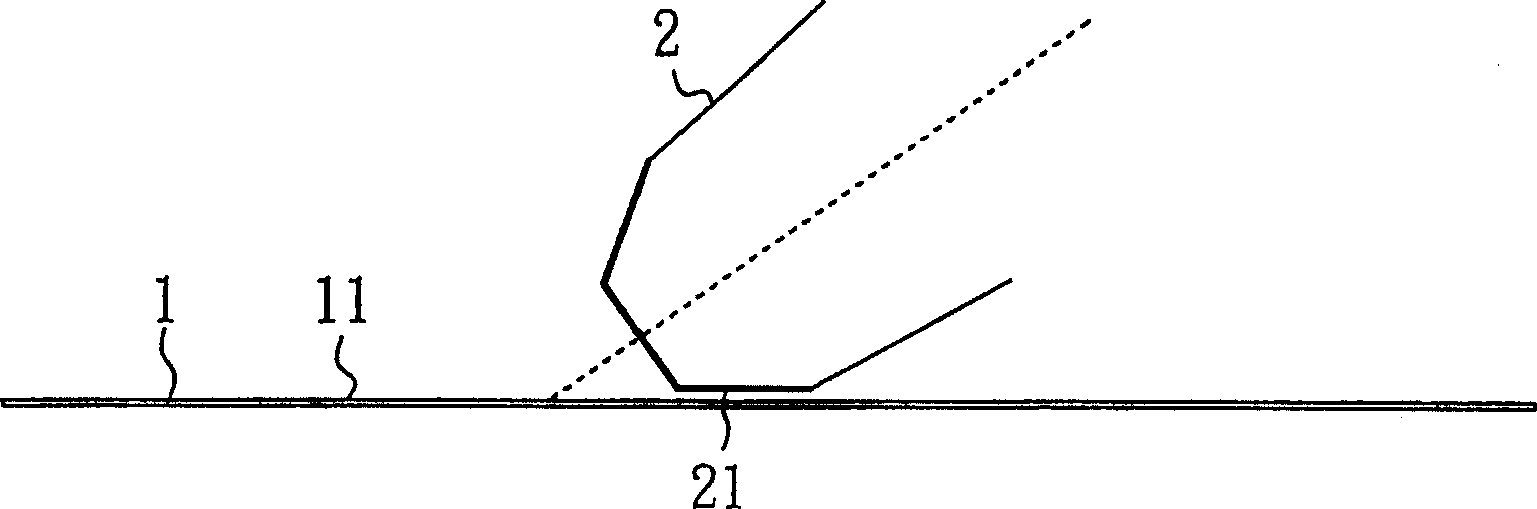

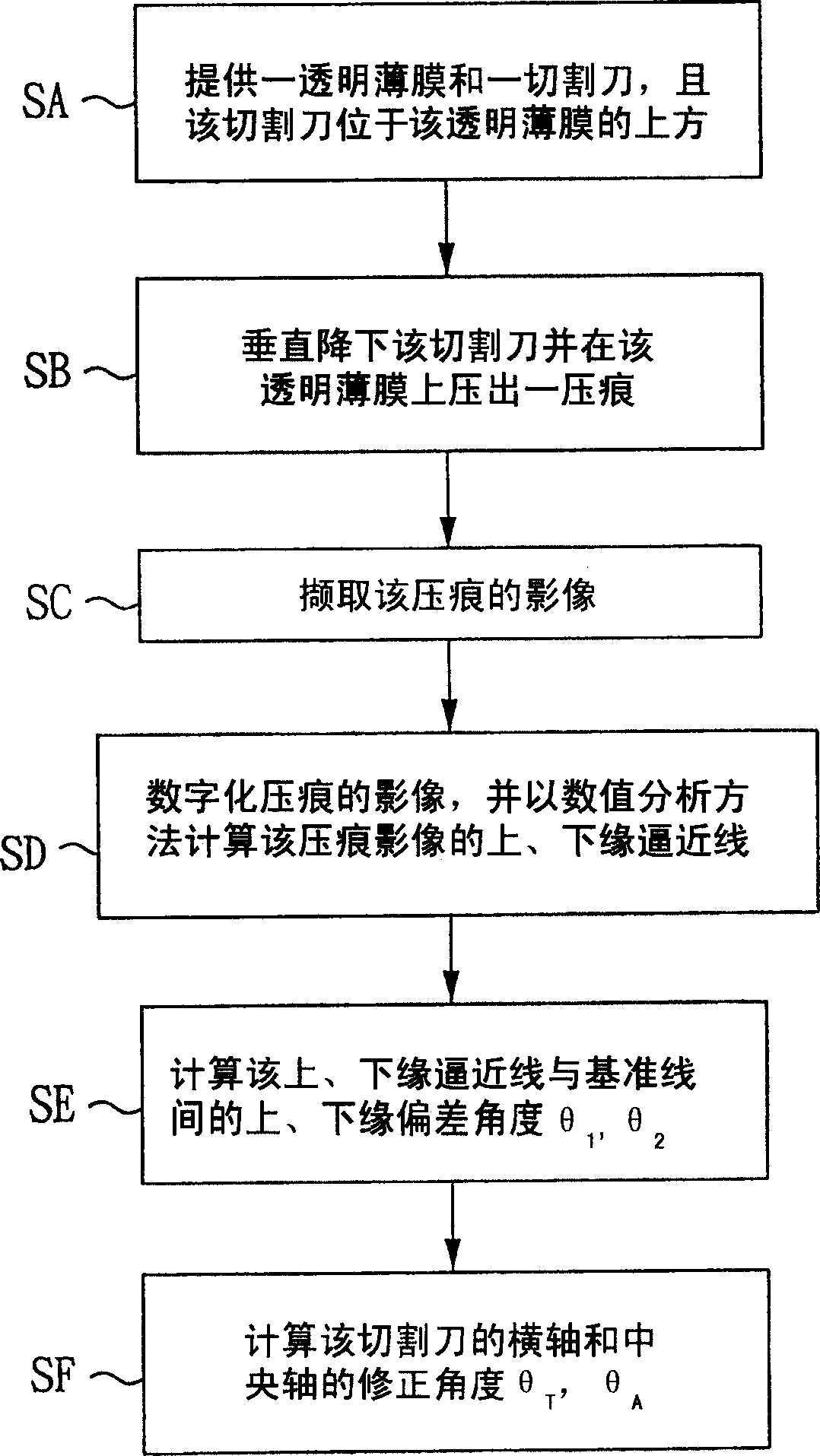

[0034] Please also see figure 1 , which is a schematic structural diagram of a preferred embodiment of the present invention; figure 2 is a schematic diagram of a cutting knife and a transparent film in a preferred embodiment of the present invention; and image 3 It is a flow chart of a preferred embodiment of the present invention, wherein a machine table 9 is shown, and a transparent film 1 (Mylar), a cutting knife 2, and an image capture device 4 are assembled on this machine table 9, wherein The cutting knife 2 is located above the transparent film 1, and the cutting knife 2 includes a central axis (A axis) and a transverse axis (T axis). In addition, the aforementioned image capture device 4 uses a CCD camera in this embodiment, and the cutting knife 2 is a diamond cutting knife in this embodiment, and the cutting knife 2 has a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com