Control valve for variable displacement compressor

A technology of positive displacement compressor and control valve, applied in the field of control valve, can solve problems such as oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

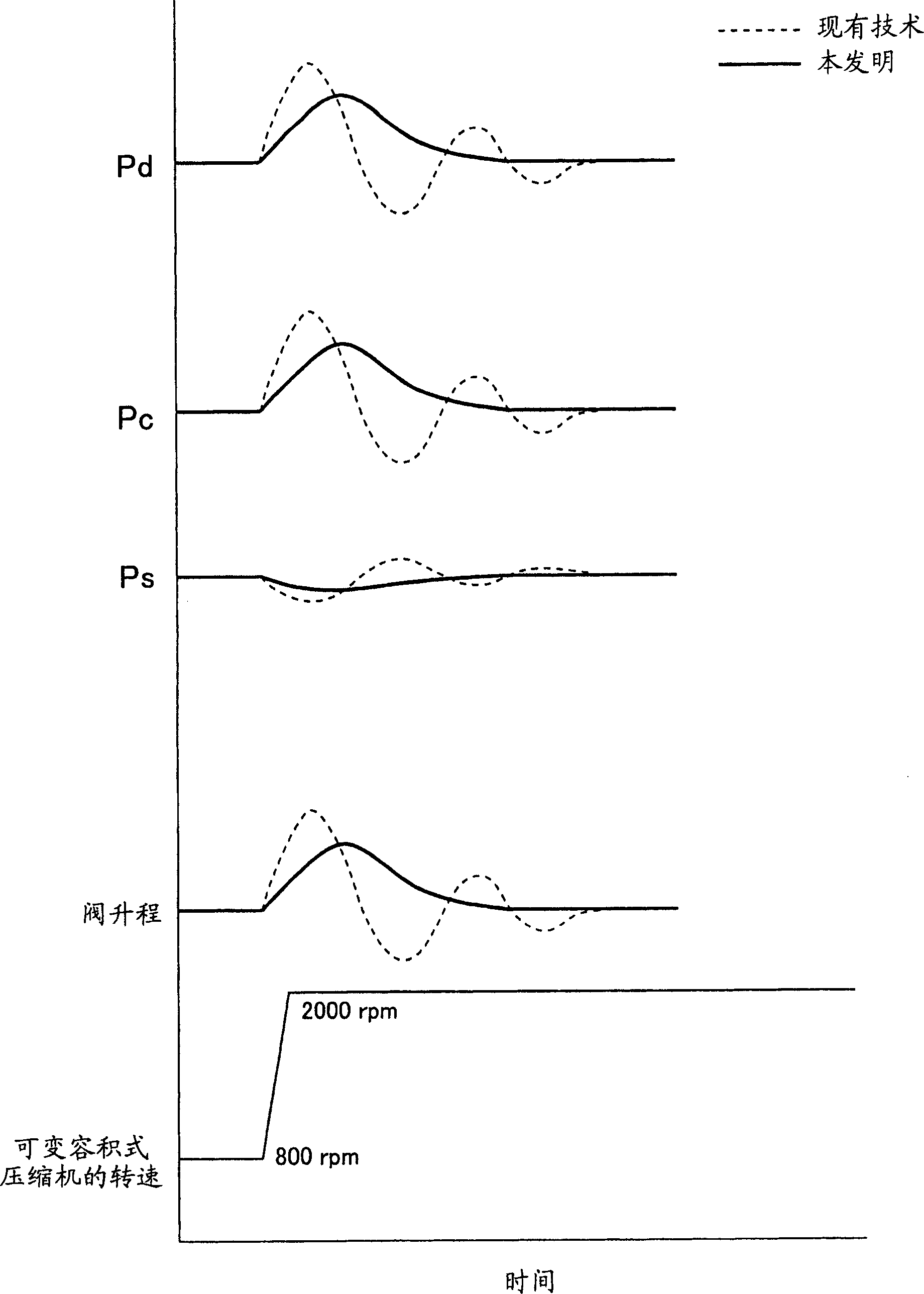

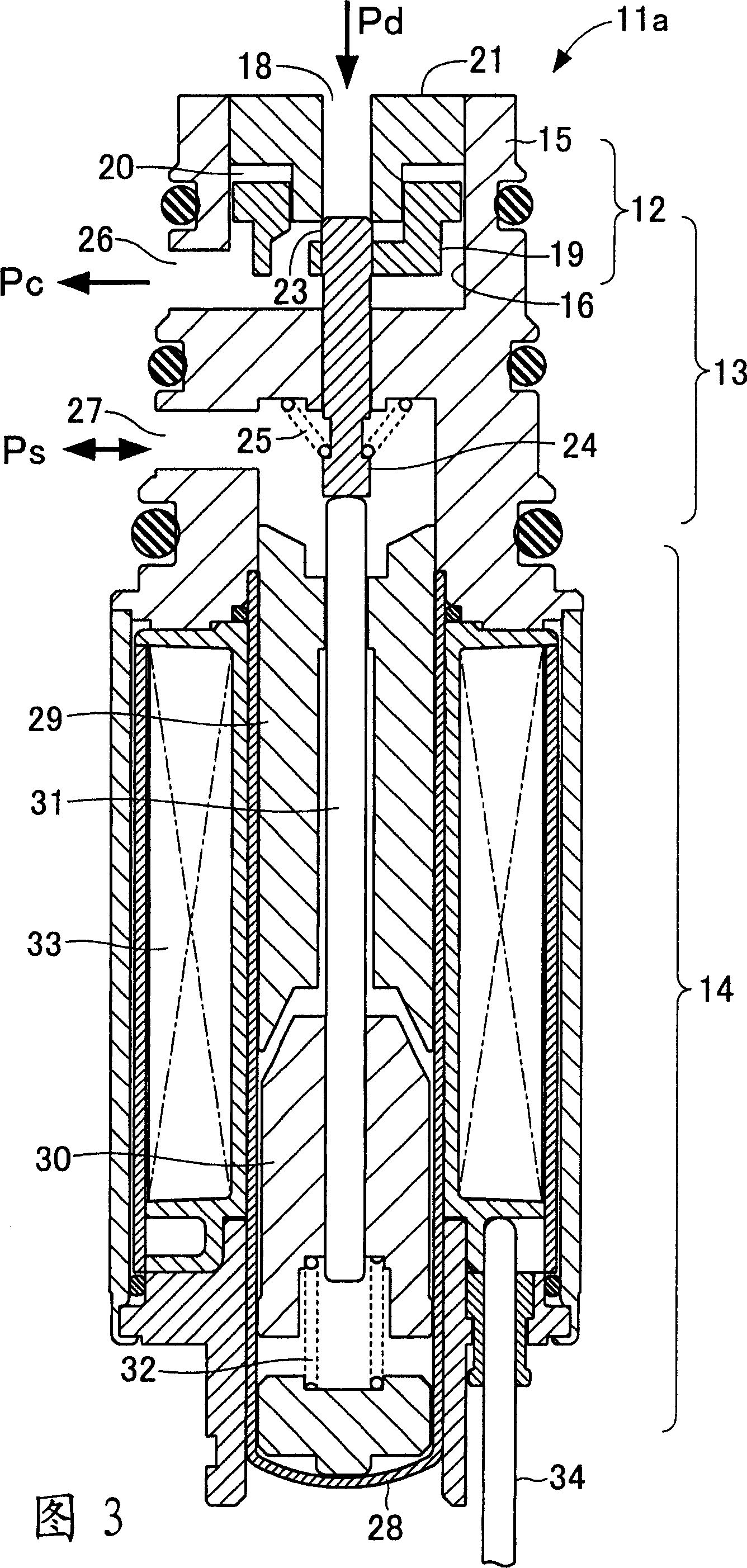

[0022] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

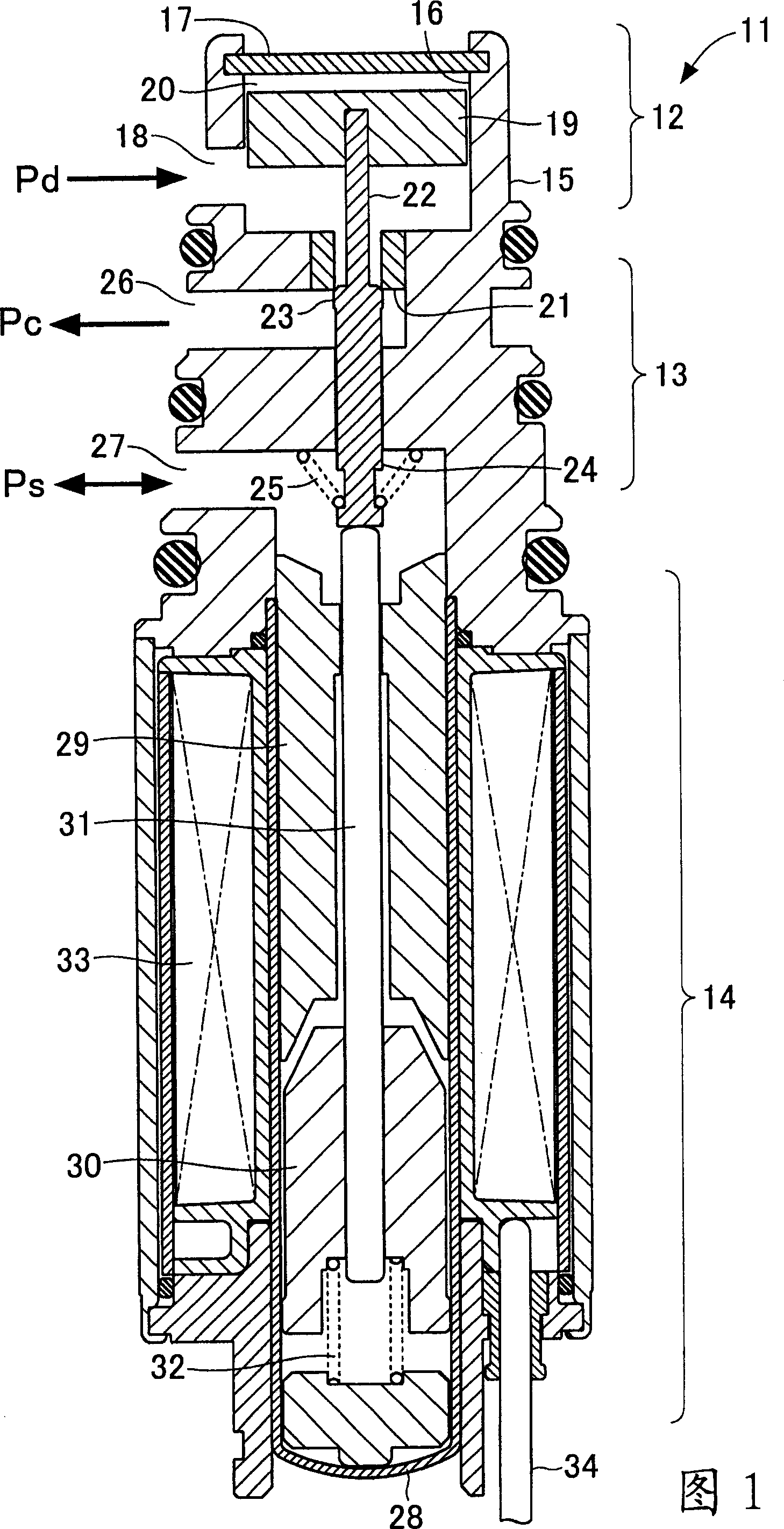

[0023] 1 is a central longitudinal sectional view schematically showing a control valve for a variable displacement compressor according to a first embodiment of the present invention.

[0024] The control valve 11 includes: a pressure sensing portion 12 which senses a rapid change in the discharge pressure Pd; a valve portion 13 which senses the pressure difference (Pd-Ps) between the discharge pressure Pd and the suction pressure Ps, thereby controlling the The flow rate of refrigerant flowing from the discharge chamber into the crankcase; and the solenoid 14, which can be set from the outside to a predetermined value to which the differential pressure (Pd-Ps) is controlled by the control valve, are along the arranged on the same axis.

[0025] The main body 15 including the pressure sensing part 12 and the valve part 13 has a cylinder 16 formed in it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com