Magnetron cooling fin

A heat sink and magnetron technology, applied in discharge tubes, microwave heating, time-of-flight electron tubes, etc., can solve problems such as limited heat transfer area of heat sinks and limited cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

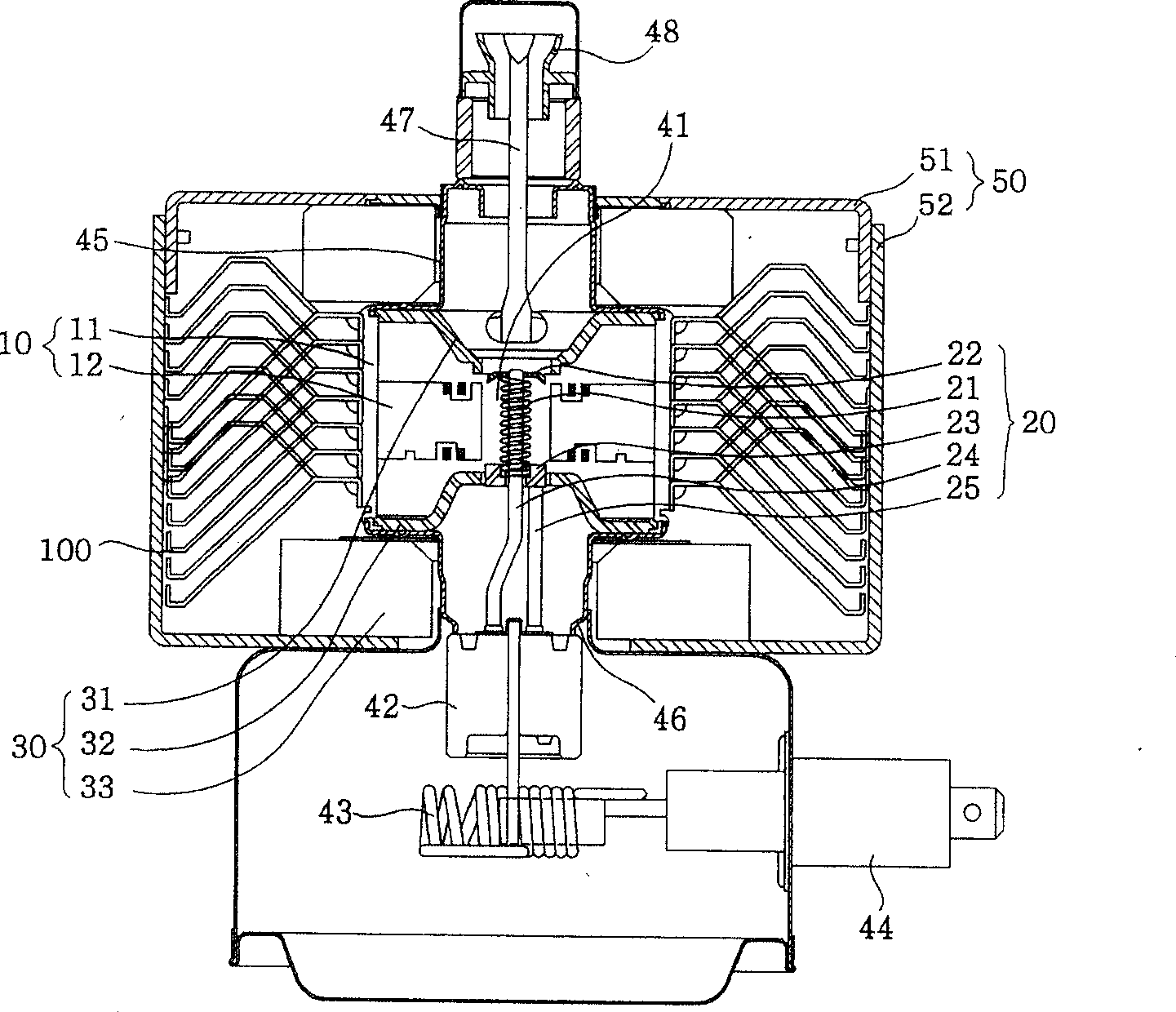

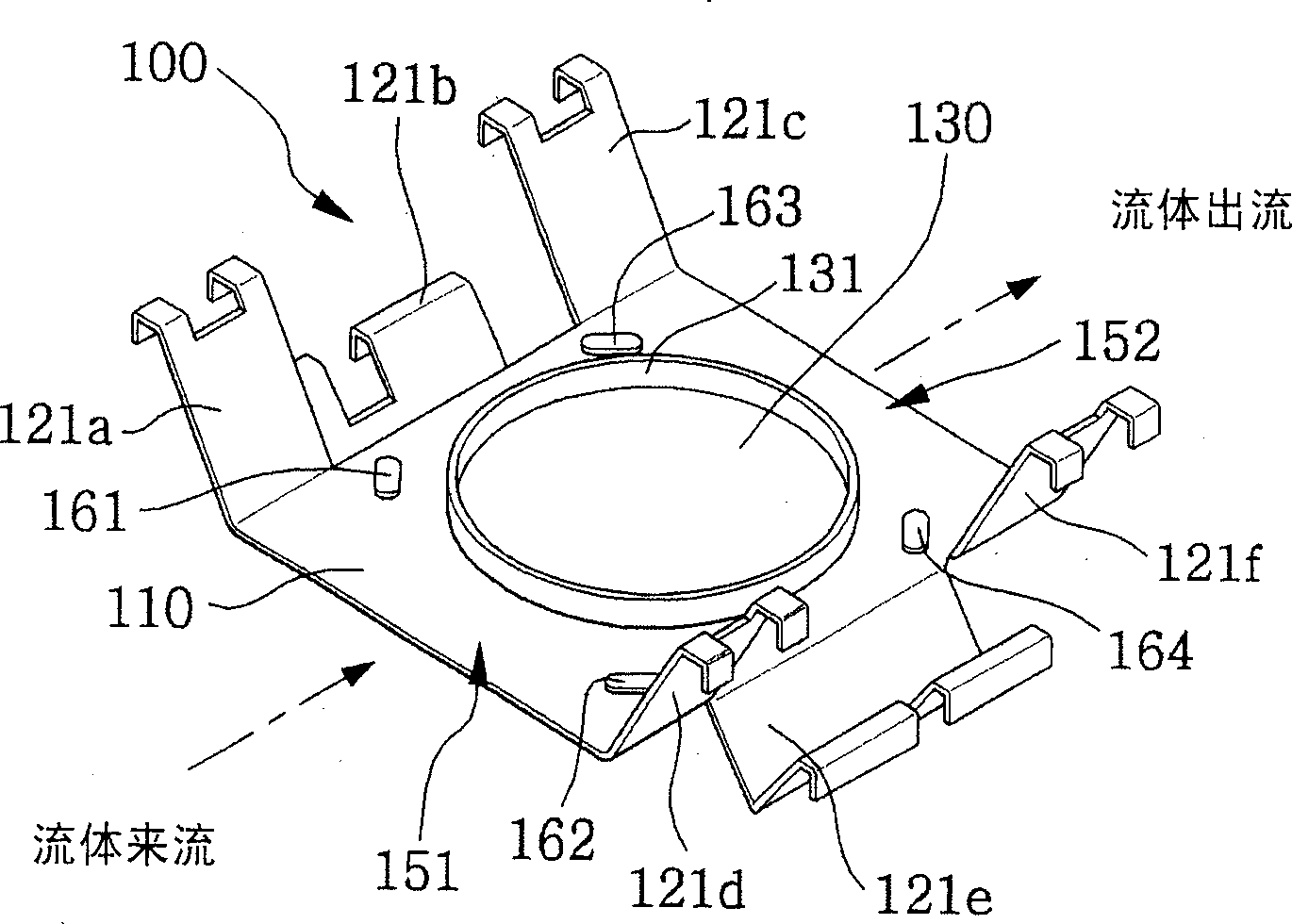

[0023] The magnetron heat sink according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

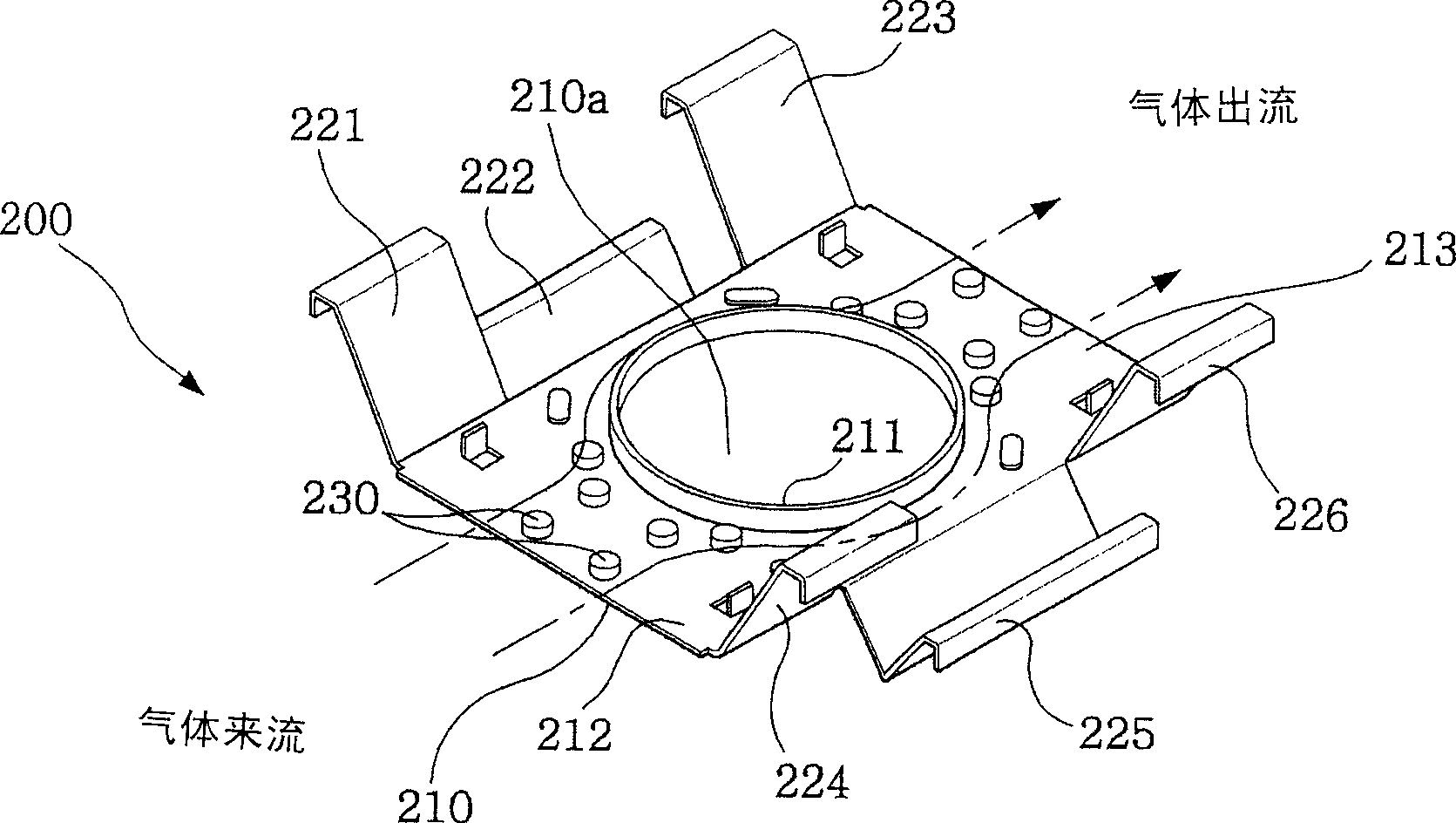

[0024] refer to image 3 , the magnetron cooling fin 200 according to the present invention comprises: a planar body 210, which has a flange-shaped through hole 210a through which the anode passes and is connected in the through hole 210a; a plurality of connection parts 221, 222 , 223, 224, 225 and 226, the connecting member extends outwards and bends at the edge of the flat body 210; One side of the planar body 210 protrudes.

[0025] Preferably, in the thus configured magnetron heat sink according to the present invention, the turbulence-promoting protrusions 230 protrude in the same direction as the protrusions 211 protruding from the edge of the flange-type through hole 210a. .

[0026] At the same time, the turbulence-enhancing protrusions 230 are set to satisfy the relationship P / H=1-10, wherein P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com