Self-aligning grinding wheel

A grinding wheel and self-adjusting technology, which is applied in the direction of bonded grinding wheels, abrasive materials, metal processing equipment, etc., can solve the problem of large radial runout error of the outer circular surface, high efficiency cannot be brought into play, and large coaxiality error between the grinding wheel and the spindle and other problems, to achieve the effects of easy popularization and application, avoiding glass edge collapse, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

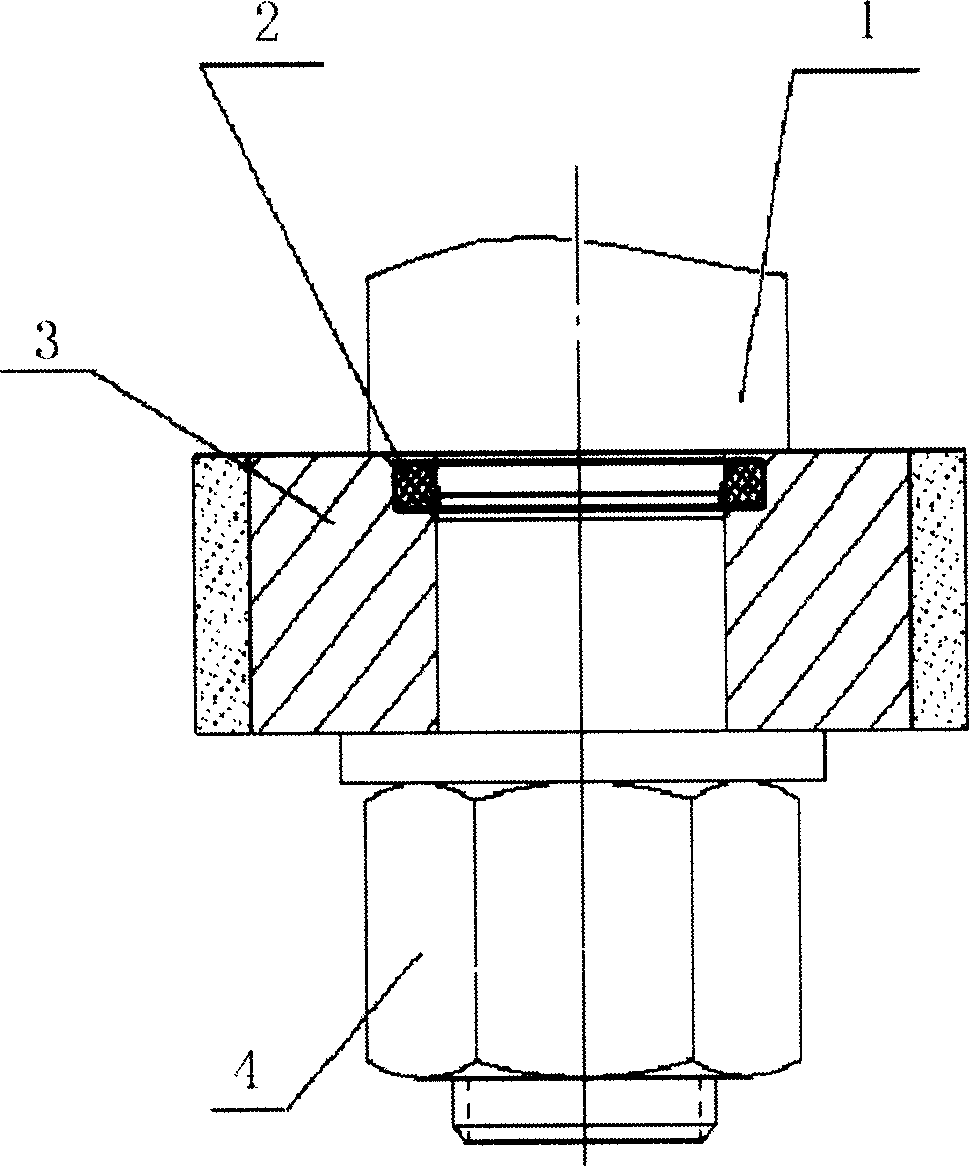

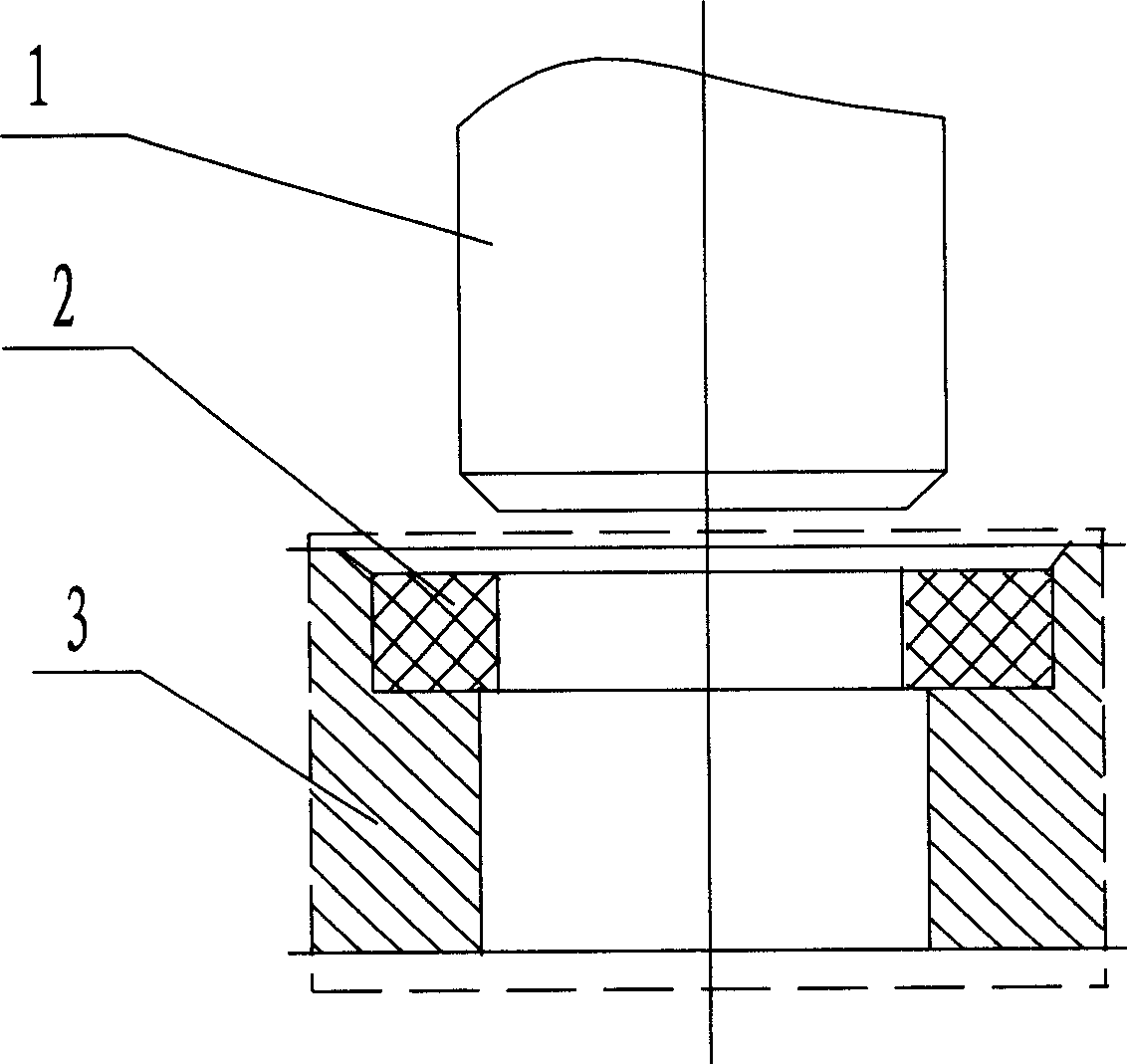

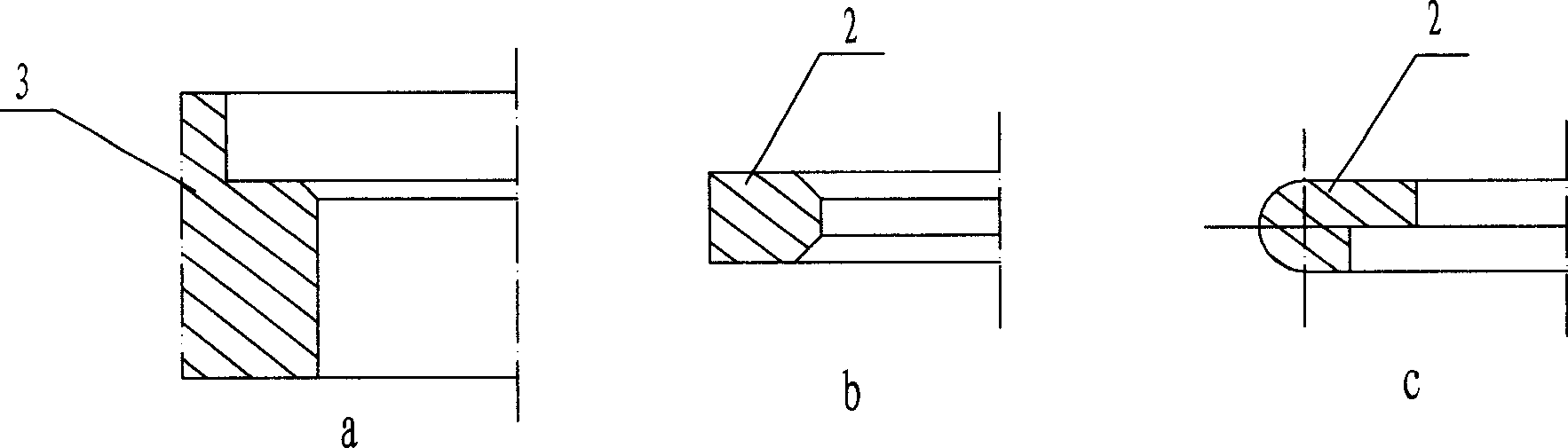

[0021] The diameter of the grinding wheel is 600mm, the thickness of the grinding wheel is 200mm, the diameter of the central hole is 32mm, and the number of annular grooves is 1. The annular groove is located at one end of the central hole, and there is no upper groove wall. The section of the groove is L-shaped, and the lower edge of the groove is chamfered, such as image 3 as shown in a. The depth of the groove is 200 mm, and the width of the groove is 100 mm. The outer diameter of the elastic ring matches the annular groove, the outer diameter is 432mm, the thickness is 98mm, the inner diameter is 22mm smaller than the central hole diameter by 10mm, and its cross section is rectangular with chamfering, such as image 3 as shown in b; or the section of the elastic ring is L-shaped, and its outer ring surface is a convex surface, such as image 3 as shown in c.

example 2

[0023] The diameter of the grinding wheel is 150mm, the thickness of the grinding wheel is 20mm, the diameter of the center hole is 22mm, the number of annular grooves is 2, and the cross section of the groove is V-shaped, such as Figure 4 as shown in a. The depth of the groove is 50 mm, and the width of the groove is 5 mm. The outer diameter of the elastic ring is 122mm, the thickness is 5mm, the inner diameter is 17mm smaller than the diameter of the central hole 5mm, and its cross-section is 0-shaped, such as Figure 4 as shown in b; or the section of the elastic ring is V-shaped, and its outer ring surface is a convex surface, such as Figure 4 as shown in c.

example 3

[0025] The diameter of the grinding wheel is 450mm, the thickness of the grinding wheel is 150mm, the diameter of the center hole is 22mm, the number of annular grooves is 12, and the cross section of the groove is 匚-shaped, such as Figure 5 as shown in a. The depth of the groove was 100 mm, and the width of the groove was 8 mm. The outer diameter of the elastic ring is 222mm, the thickness is 7.5mm, and its inner diameter is 14mm smaller than the central hole diameter of 8mm. The cross-sectional shape of the elastic ring is U-shaped. Figure 5 as shown in b; or the section of the elastic ring is rectangular, and its upper and lower surfaces and inner and outer ring surfaces are zigzag, such as Figure 5 as shown in c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com