Sleeve for a printing cylinder and the printing cylinder

A technology of printing presses and cylinders, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc., can solve the problem of high storage costs, and achieve the effect of low storage costs and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

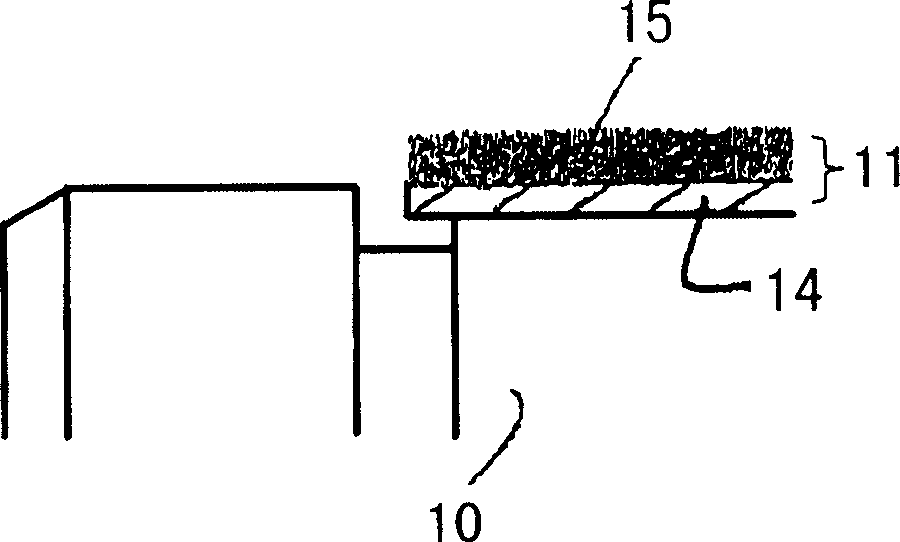

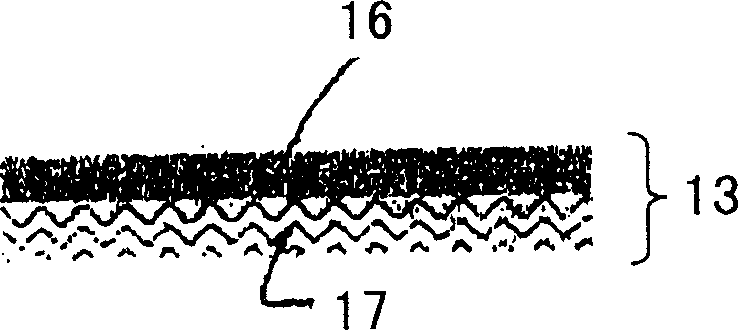

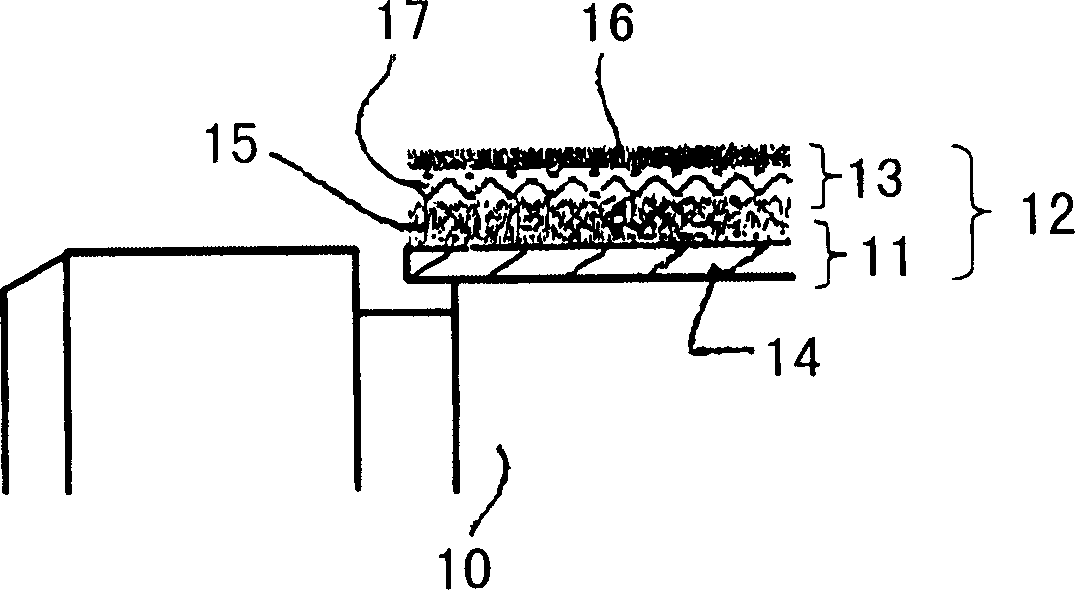

[0016] In the following text, reference Figure 1-3 The present invention is described in more detail.

[0017] figure 1 Details of the printing press cylinder 10 (ie transfer cylinder or blanket cylinder) are shown. The basic body 11 of the sleeve, generally designated 12 , is radially adjacent to the surface of the drum 10 on the outside. Furthermore, in addition to the basic body 11, the sleeve 12 has a replaceable or replacement body 12 (cf. figure 2 ). image 3 A sleeve 12 and a drum 10 are shown, wherein the sleeve 12 includes a basic body 11 and a replaceable body 13 .

[0018] In the context of the present invention, a sleeve 12 for a cylinder 10 of a printing press is proposed, the sleeve 12 comprising a basic body 11 and a replaceable body 13 . The base body 11 is fixed and preferably permanently connected in a non-detachable manner to the cylinder 10 of the printing press. The base body 11 , which is fastened inseparably to the drum 10 , can only be detached ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap