Internal-bevel and venturi assembled flowmeter with variable area

A Venturi tube and variable area technology, which is applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detection by measuring pressure difference, etc., can solve the problem of low measurement accuracy of throttling flowmeters, high requirements for on-site installation conditions, and flow problems. Large resistance and other problems, to achieve the effect of small flow resistance, high signal-to-noise ratio, and short straight pipe sections before and after

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

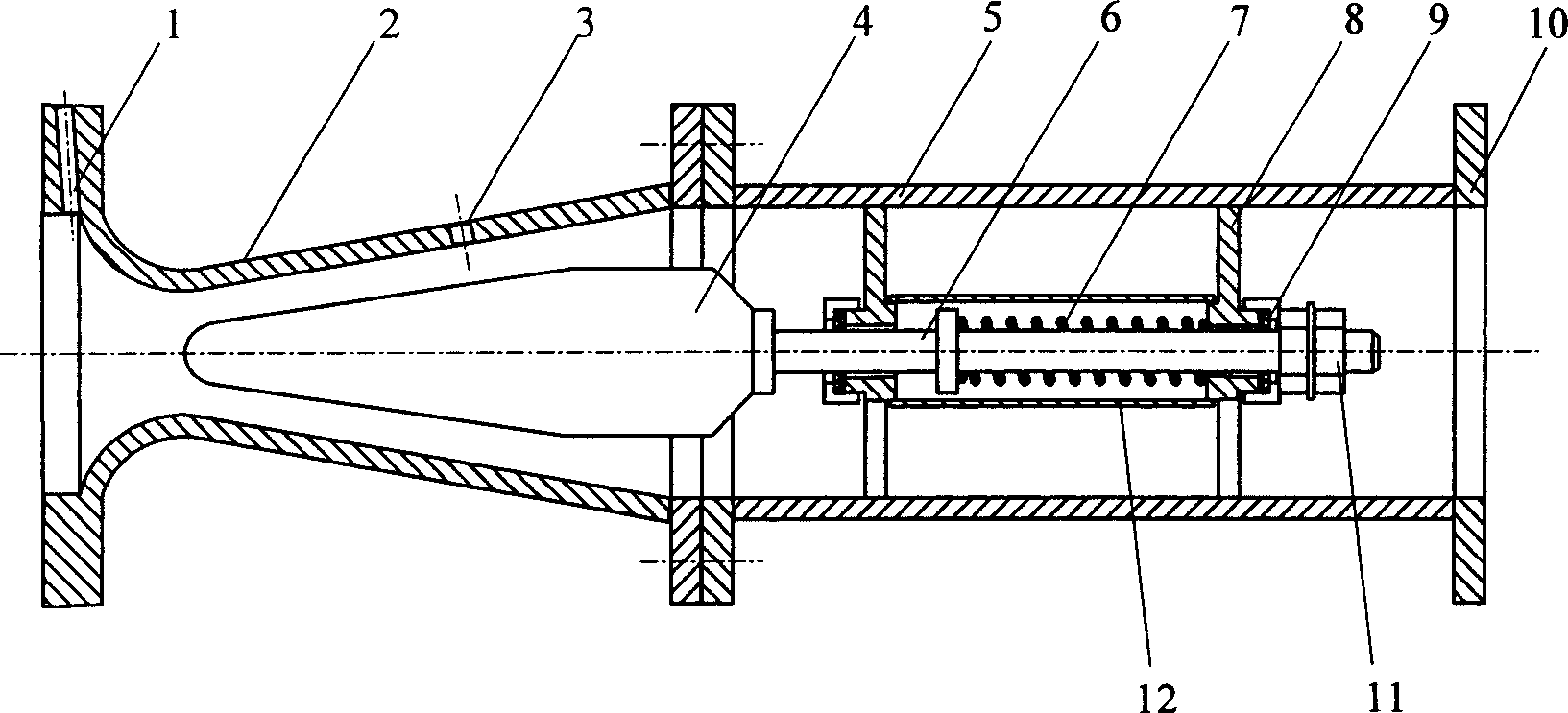

[0012] As shown in the accompanying drawings, the present invention includes a nozzle-type Venturi tube 2 with a high-pressure pressure-taking port 1 on the flange and a low-pressure pressure-taking port 3 in the expansion section. The nozzle-type Venturi tube 2 is equipped with a cone core 4 , the large end of the cone core 4 faces the large port of the nozzle-type Venturi tube 2, the large end of the nozzle-type Venturi tube 2 is connected to the outer tube 5, the large end of the cone core 4 is fixedly connected with a slide rod 6, and the two ends of the slide rod 6 It is sealed with a dust-proof sealing washer and a nut 9. A balance spring 7 is set on the slide bar 6 and installed in the dust cover 12 of the outer tube 5. The dust cover 12 is supported in the middle of the outer tube 5 by a support 8, and the slide bar 6 can move axially, and adjusting nut 11 is ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com