Radiator and its production thereof

A technology of heat dissipation device and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, instrument cooling, instrument, etc., which can solve the problems of increasing the overall weight, easy deformation, and weakening heat dissipation rate of the thermal uniform temperature cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

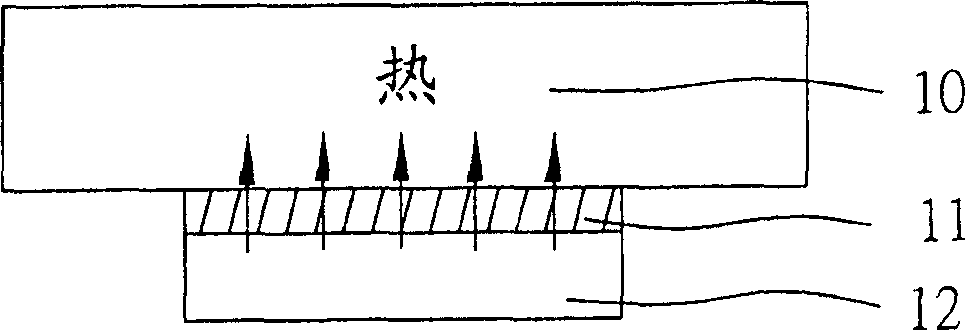

[0031] Please refer to figure 1 , which shows a schematic diagram of a heat dissipation device in a preferred embodiment of the present invention and the heat-generating components applied thereto. The heat dissipating device 10 of the present invention is a heat uniform chamber (vapor chamber), which is applied to a heat generating component 12, such as a CPU. exist figure 1 Among them, a metal bottom plate 11, such as a copper bottom plate, can be directly attached to the top of the heating component 12, and the heat sink 10 is arranged on the bottom plate 11, so the heat generated by the heating component 12 can be directly conducted through the bottom plate 11. to the heat uniform temperature chamber 10, and quickly transfer heat to the outside through the heat uniform temperature chamber 10.

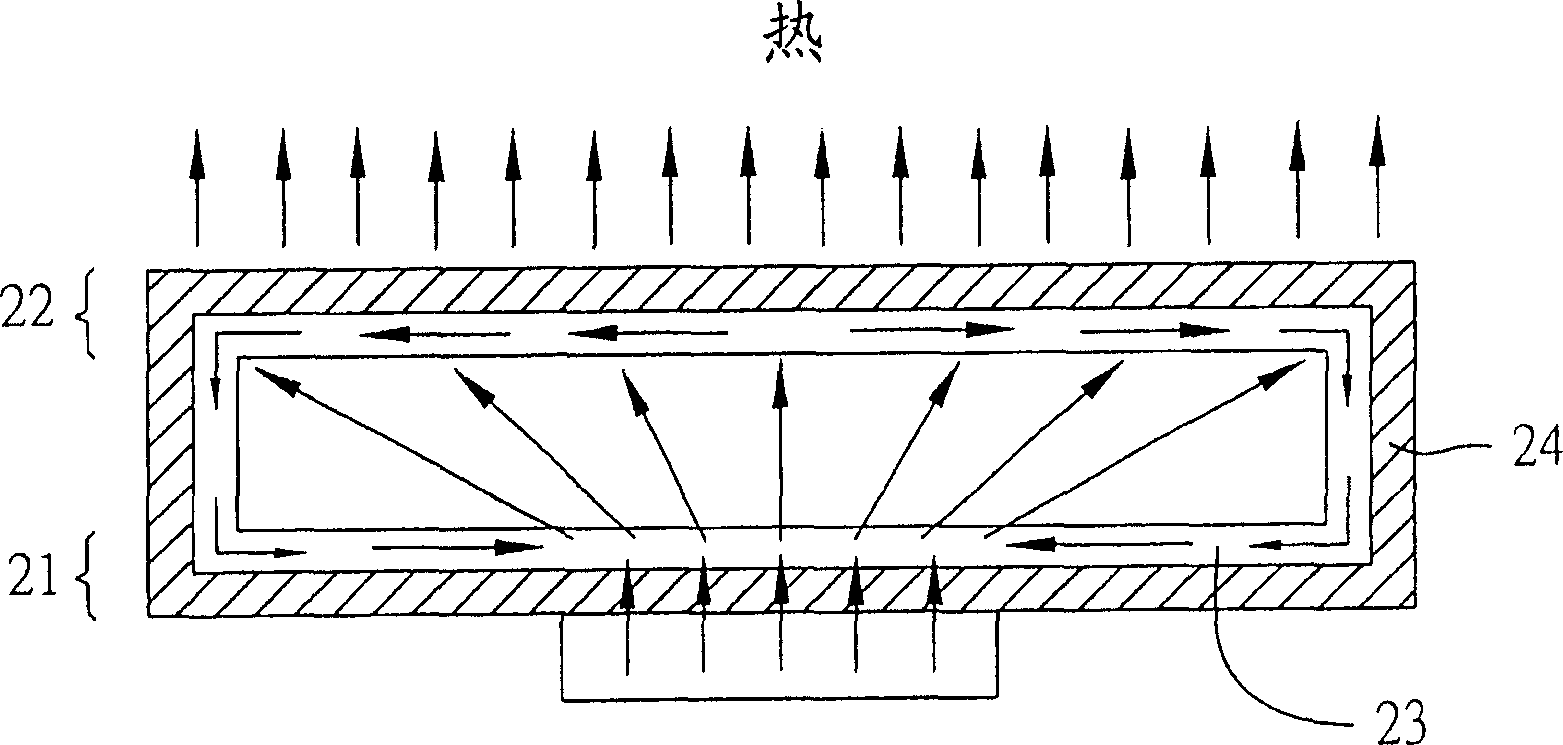

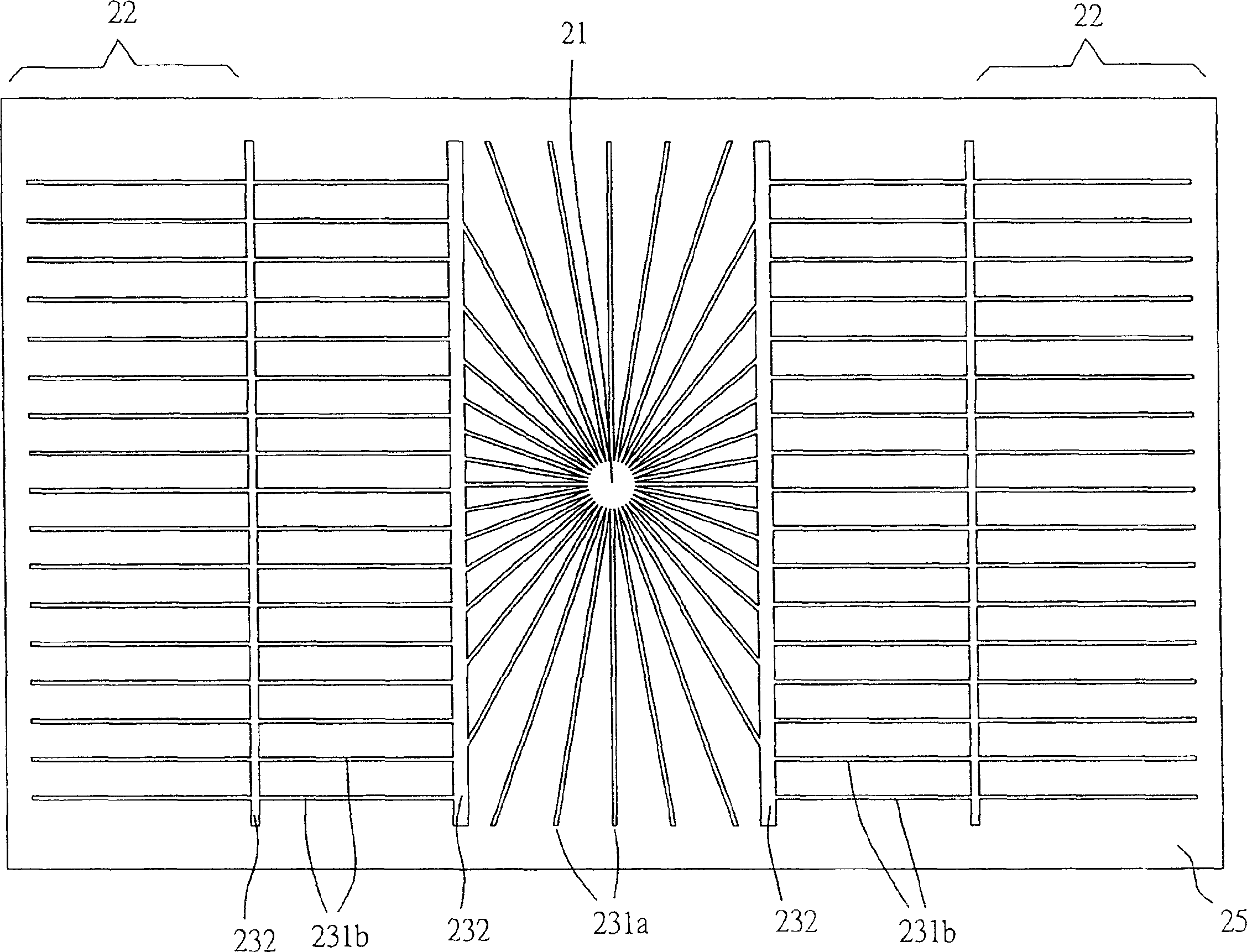

[0032] Please refer to figure 2 , which shows a cross-sectional view of the thermal uniform chamber. The heat equalization cavity 10 includes a cavity, a working fluid, an evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com