Roller type linear slide rail

A technology of linear slides and rollers, which is applied in the direction of linear motion bearings, large fixed members, bearings, etc., can solve the problems of high injection molding precision, difficult forming, and high difficulty, so as to reduce the assembly time of parts and molds Low-cost, easy-to-manage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

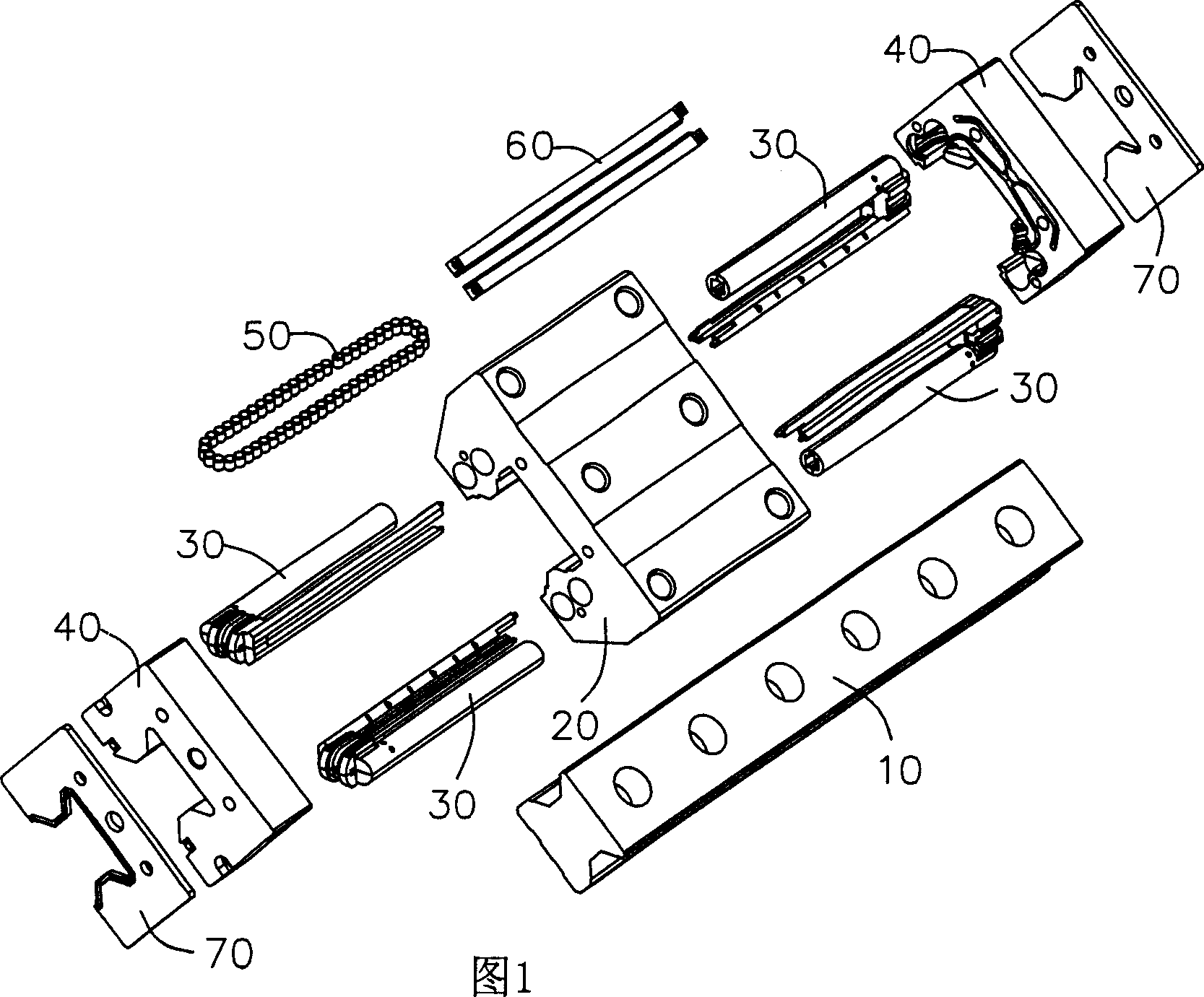

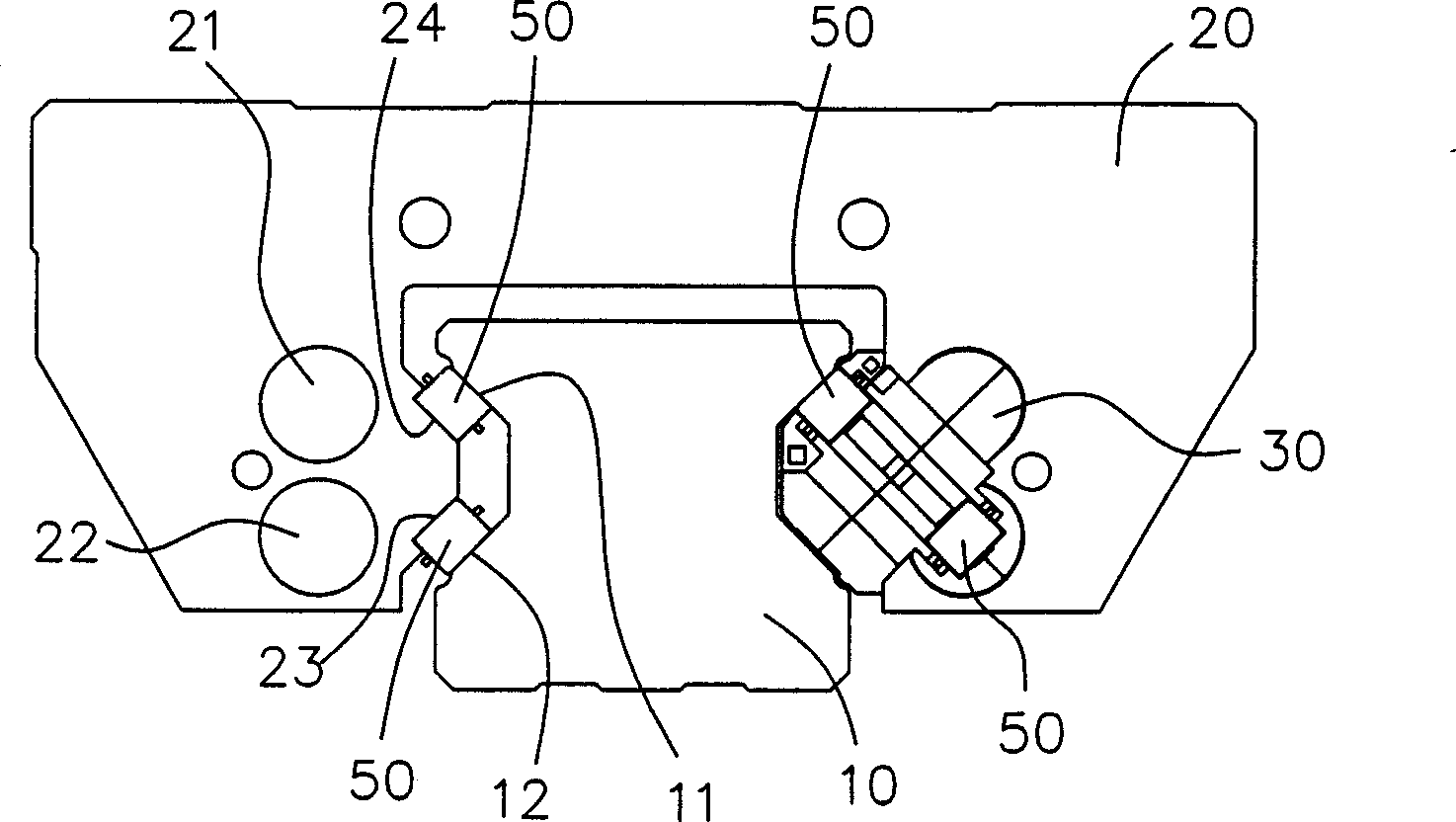

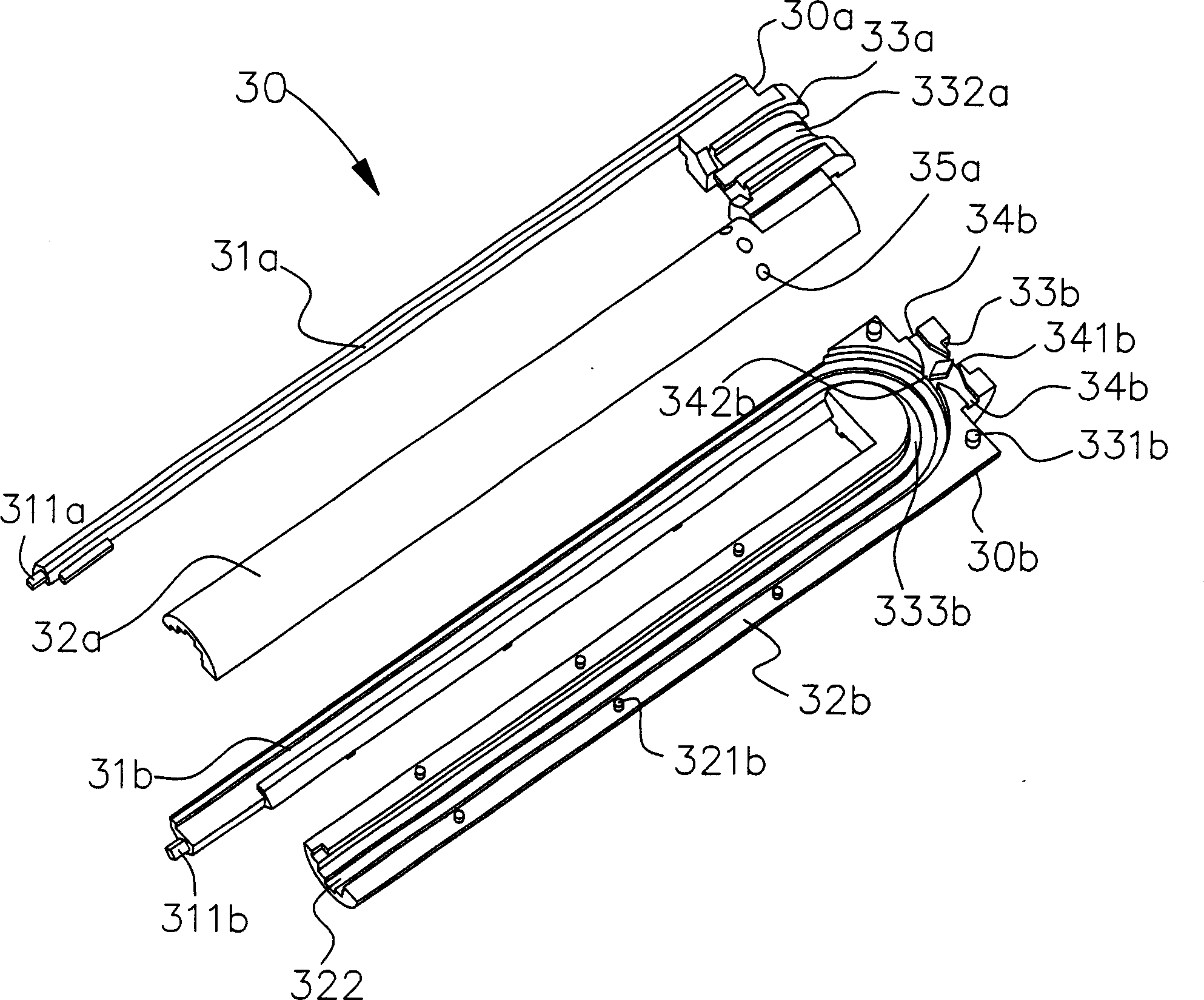

[0060] Fig. 1 is an exploded perspective view of a roller slide rail of the present invention; figure 2It is a schematic view of the end surface of the roller slide rail without end cover of the present invention; the roller linear slide rail includes: the slide rail 10 is an elongated member with four rolling surfaces 11 and 12, and one has four return holes 21 and 22 and the slider body 20 of the four rolling surfaces 23 and 24, the half-cycle module 30, the end cover 40, the roller module 50 composed of a plurality of rollers, the dust-proof sheet 60 and the oil scraper 70, etc., wherein the slider The main body 20 is sleeved on the slide rail 10 to move, and the rolling surfaces 11 and 12 of the slide rail 10 coincide with the rolling surfaces 24 and 23 of the slider body 20, respectively causing a row of roller modules 50 to roll therebetween, and the half-cycle module 30 is moved by the sliding The end faces of the block body 20 are inserted into the return holes 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com