Lengthening reform technology of ship

A ship and process technology, applied in ship components, ship construction, transportation and packaging, etc., can solve the problems of not suitable for container ship refitting, complicated process operation, difficult deviation correction, etc., and achieve small error, wide applicability and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

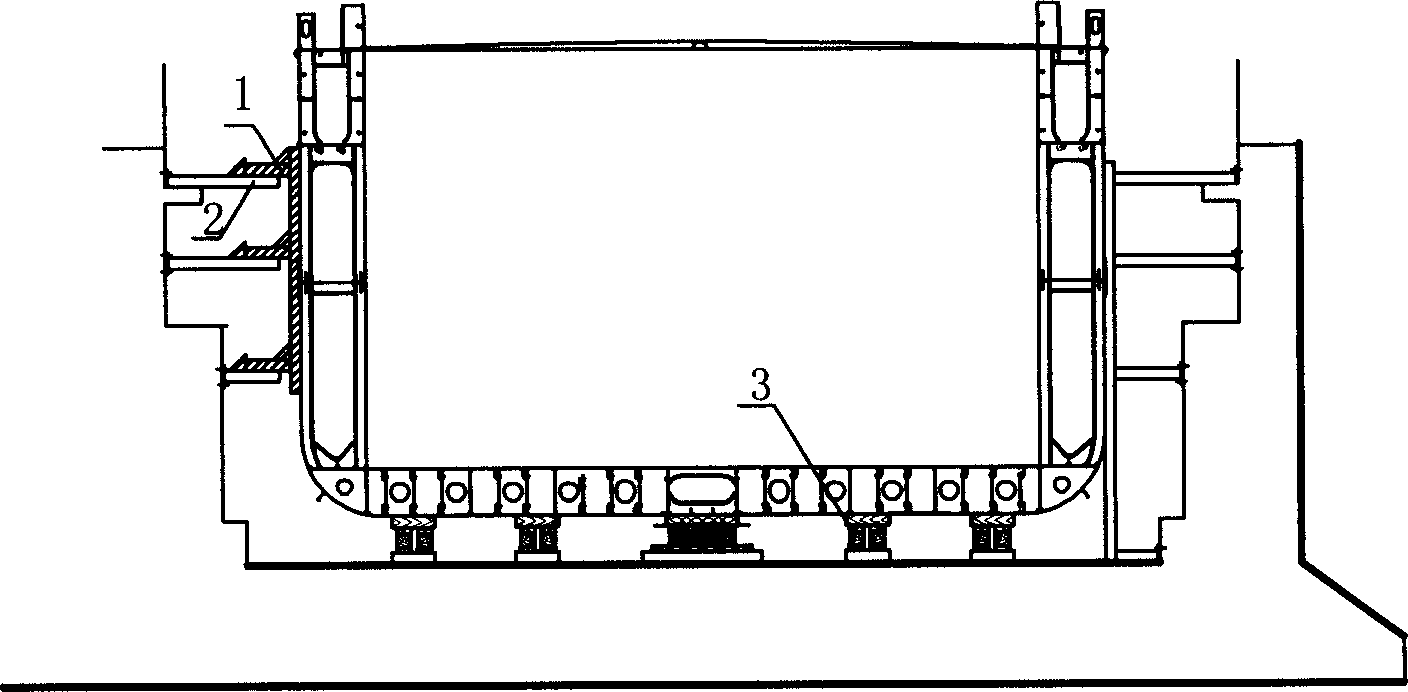

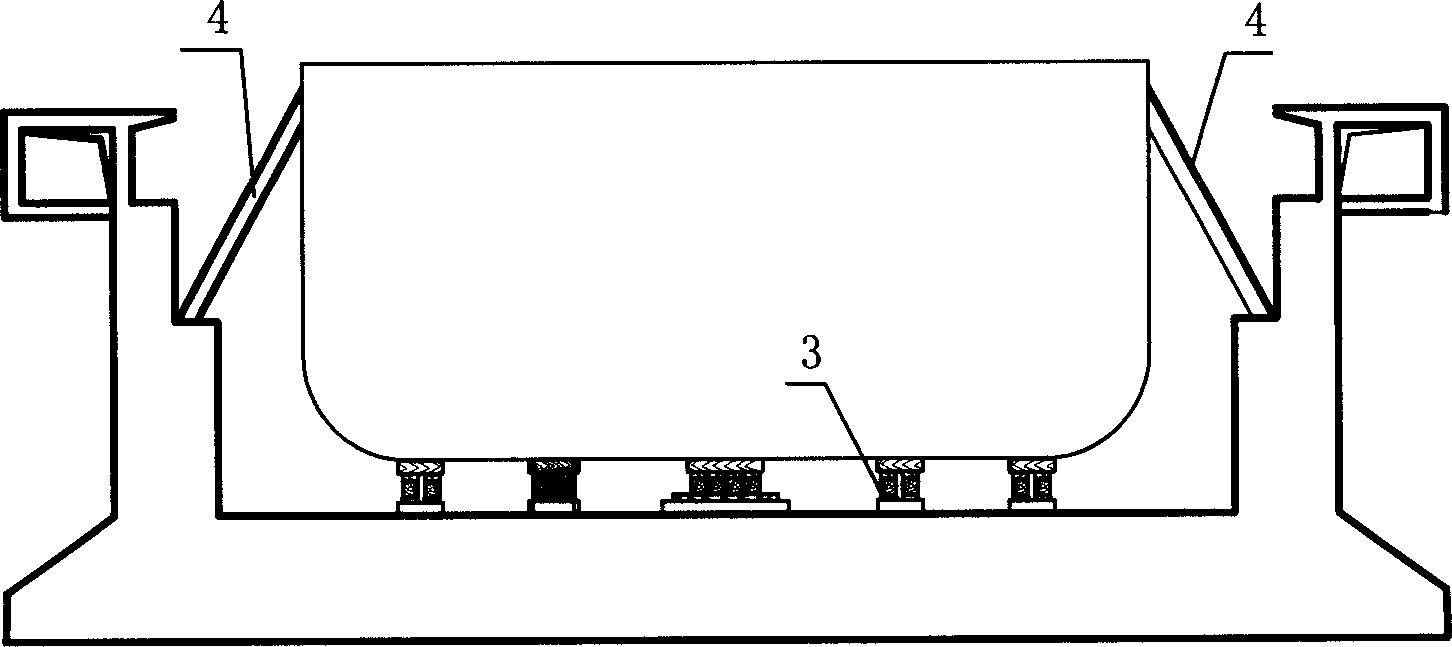

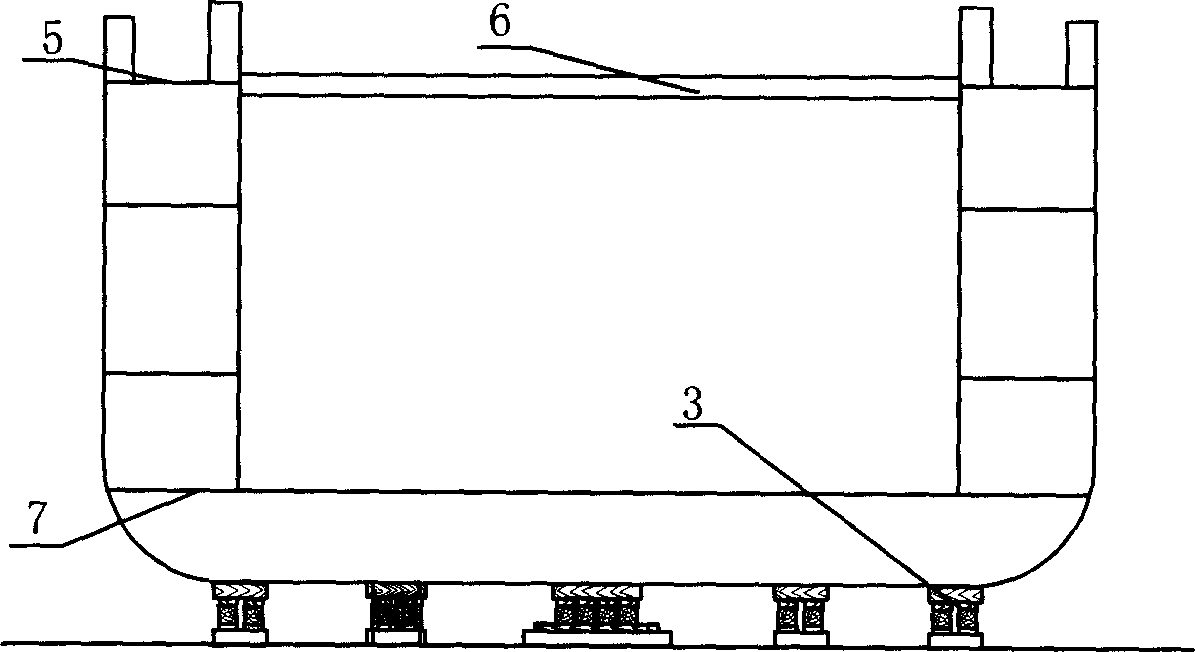

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is illustrated by a refitted ship in Papua. The whole process includes section cutting, section displacement and section closing. The measurement and establishment of the mouth and datum line, the measurement and establishment of the cutting line, the establishment of the strengthening device, the inspection after cutting and the addition of water-retaining bulkheads and ballast pontoons; The closing process includes the preparation work before the hull closing, rough positioning and closing of the extended middle section, precise positioning, welding, closing and positioning of the bow half ship, weld inspection, tightness test and main dimension measurement report.

[0034] The main steps are described in detail as follows:

[0035] 1. Establishment of baselines and auxiliary lines in the dock

[0036] Measure the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com