Manufacturing method of full extinction polyamide 66 resin and fiber

A technology of matting polyamide and its manufacturing method, which is applied to the direction of single-component polyamide artificial filament, etc., can solve the problems of high production cost, complex process, expensive equipment cost, etc., and achieve low production cost, good economic benefits, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

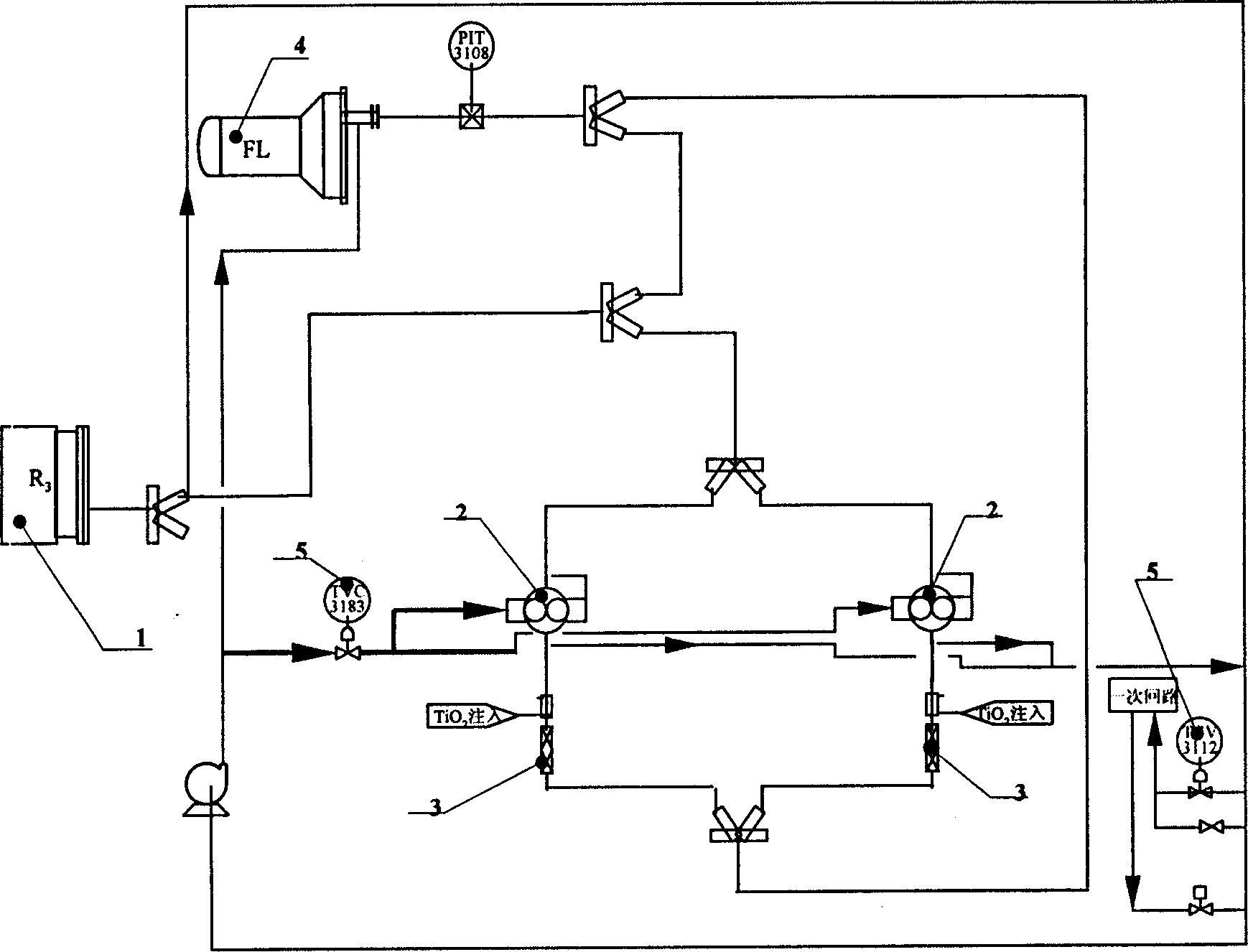

Method used

Image

Examples

Embodiment Construction

[0016] 1. Preparation of matting agent solution

[0017] Anatase-grade manganese ion-coated titanium dioxide was selected as the matting agent.

[0018] First put titanium dioxide into the dissolution tank, then add water to make a solution with a concentration of 30%. At the same time, add the dispersant sodium phosphate. The amount added is 0.1-0.5% of the solution. Stir well to make it evenly mixed. Then the solution was dropped into a settling tank for 30 hours of settling. The solution after sedimentation is put into the preparation tank, and it is added with water to prepare a 25% titanium dioxide solution.

[0019] 2. Preparation of polyamide 66 resin

[0020] A 50% aqueous solution of nylon 66 salt is used or a 50% concentration solution is prepared by adding solid nylon 66 salt to deionized water. After it is transported to the horizontal tubular continuous polycondensation device, it is first evaporated and concentrated under normal pressure, and then the polyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com