Production process of online fruit dyed spunlace non-woven fabric

A technology of spunlace non-woven fabric and production process, which is applied in the field of production technology of online fruit dyed spunlace non-woven fabric, can solve the problems of steam environment and operator influence, monotonous color of spunlace non-woven fabric, damage, etc. The dyeing effect is environmentally friendly, degradable, good affinity, and the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

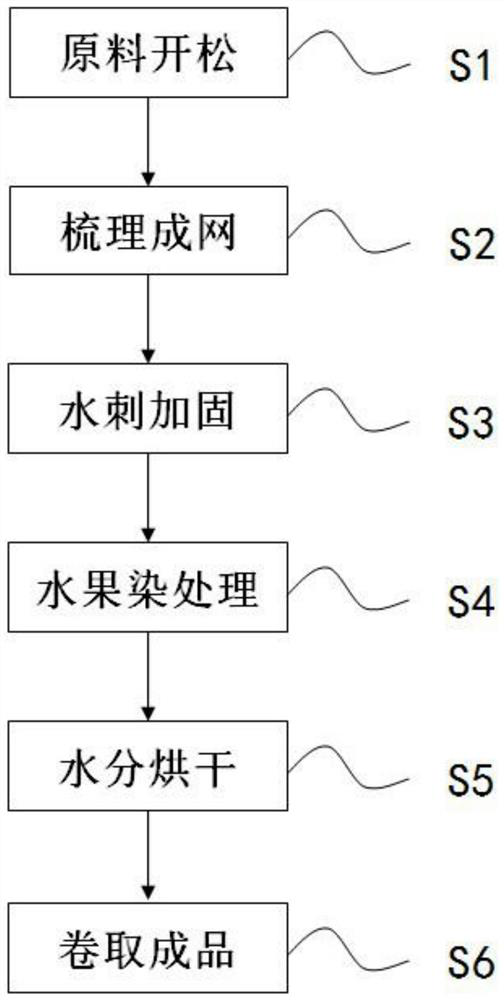

[0037] A kind of production process of online fruit dyeing spunlace non-woven fabric, the production process of this spunlace non-woven fabric comprises the following steps:

[0038] S1: Raw material opening: open the viscose fiber raw material package with a fineness of 1.7dtex and a length of 40mm and feed it into the unpacking machine. Manual selection and feeding ensure that there are no obvious foreign fibers and impurities. The raw material is conveyed through the long curtain through the horizontal opening machine. After rough loosening by the loosening machine, it is sent to the big warehouse through the fan pipeline, and then finely loosened by the fine opening machine, and the metal detection system removes metal impurities, and is stored in the transfer cotton box for use in the next process;

[0039] S2: Carding into a web: the fibers entering the air pressure cotton box through the fan duct are fed into the carding machine by means of metering and weighing curtains...

Embodiment 2

[0046] A kind of production process of online fruit dyeing spunlace non-woven fabric, the production process of this spunlace non-woven fabric comprises the following steps:

[0047] S1: Raw material opening: open the viscose fiber raw material package with a fineness of 1.7dtex and a length of 40mm and feed it into the unpacking machine. Manual selection and feeding ensure that there are no obvious foreign fibers and impurities. The raw material is conveyed through the long curtain through the horizontal opening machine. After rough loosening by the loosening machine, it is sent to the big warehouse through the fan pipeline, and then finely loosened by the fine opening machine, and the metal detection system removes metal impurities, and is stored in the transfer cotton box for use in the next process;

[0048] S2: Carding into a web: the fibers entering the air pressure cotton box through the fan duct are fed into the carding machine by means of metering and weighing curtains...

Embodiment 3

[0055] A kind of production process of online fruit dyeing spunlace non-woven fabric, the production process of this spunlace non-woven fabric comprises the following steps:

[0056] S1: Raw material opening: open the viscose fiber raw material package with a fineness of 1.7dtex and a length of 40mm and feed it into the unpacking machine. Manual selection and feeding ensure that there are no obvious foreign fibers and impurities. The raw material is conveyed through the long curtain through the horizontal opening machine. After rough loosening by the loosening machine, it is sent to the big warehouse through the fan pipeline, and then finely loosened by the fine opening machine, and the metal detection system removes metal impurities, and is stored in the transfer cotton box for use in the next process;

[0057] S2: Carding into a web: the fibers entering the air pressure cotton box through the fan duct are fed into the carding machine by means of metering and weighing curtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com