Automatic testing device of semiconductor construction element

An automated testing and semiconductor technology, applied in the direction of single semiconductor device testing, etc., can solve problems such as the inability to fully expose system-level interactions in semiconductor chips, reduce testing costs and testing time, simplify testing procedures, and improve error coverage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The aforementioned and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the accompanying drawings.

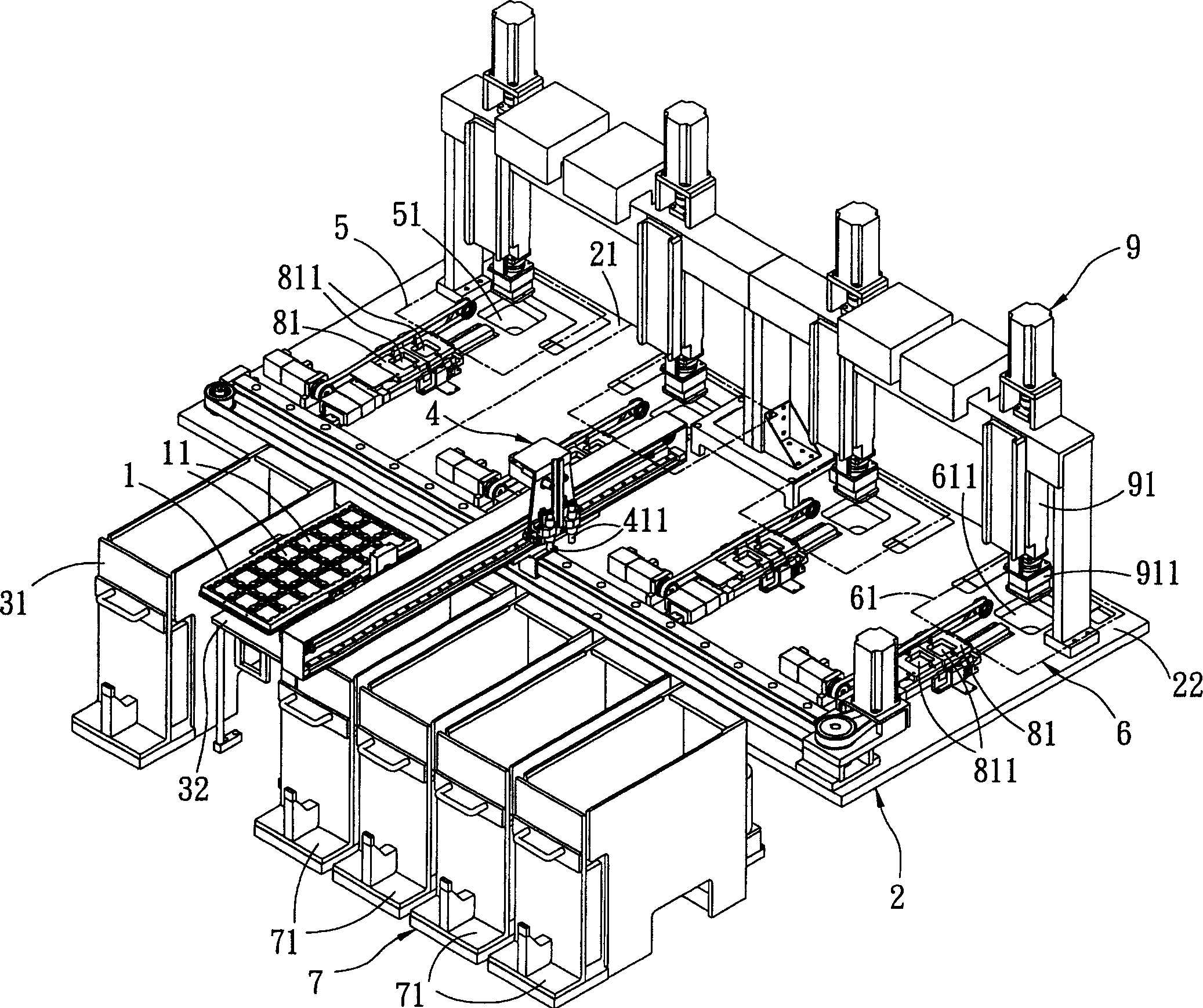

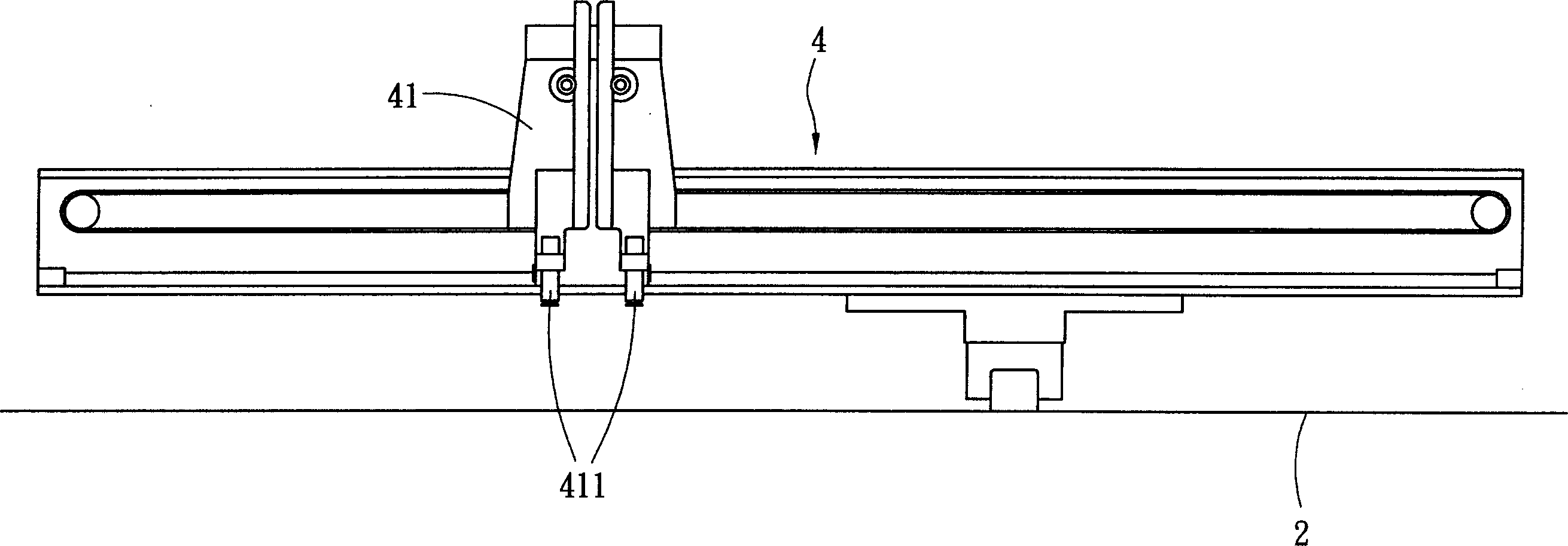

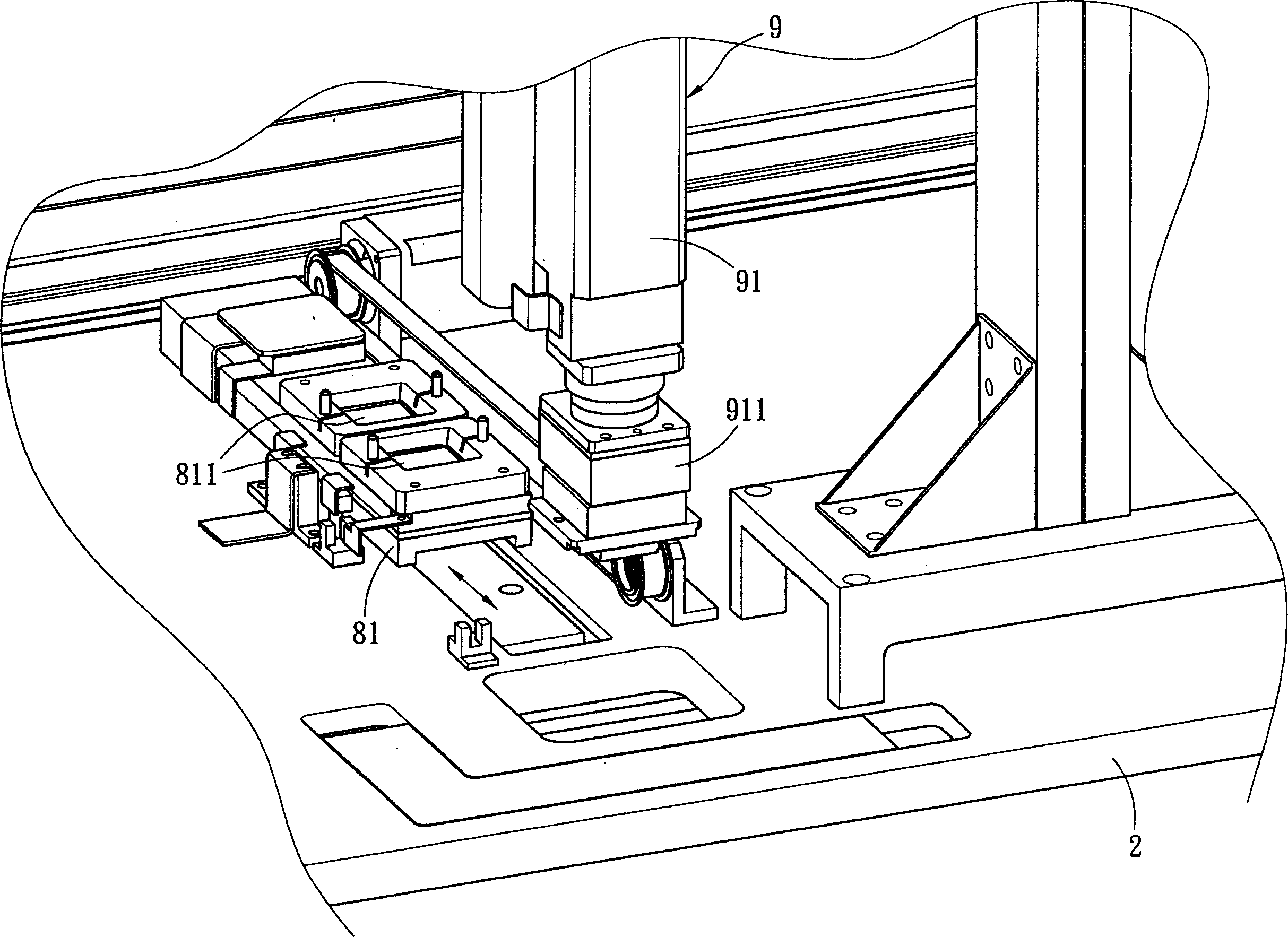

[0018] see figure 1 , 2 Shown, according to the automatic testing device of semiconductor package element of the present invention, be suitable for the semiconductor testing process after packaging, the preferred embodiment of the automatic testing device of this semiconductor package component comprises: a working platform 2, a feeding unit 3. A conveying unit 4 , a first testing unit 5 , a second testing unit 6 , and a discharging unit 7 .

[0019] The working platform 2 has a first test area 21 with a smaller area and a second test area 22 with a larger area. The feeding unit 3 is disposed on the front end of the working platform 2 and adjacent to the working platform 2 , and has a feeding box 31 . A plurality of semiconductor carrier p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com