Semi-modular rotor module

A wheel, lug technology applied in the field of rotary regenerative heat exchangers, which can solve the problems of expensive, rework, lack of workshop fixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

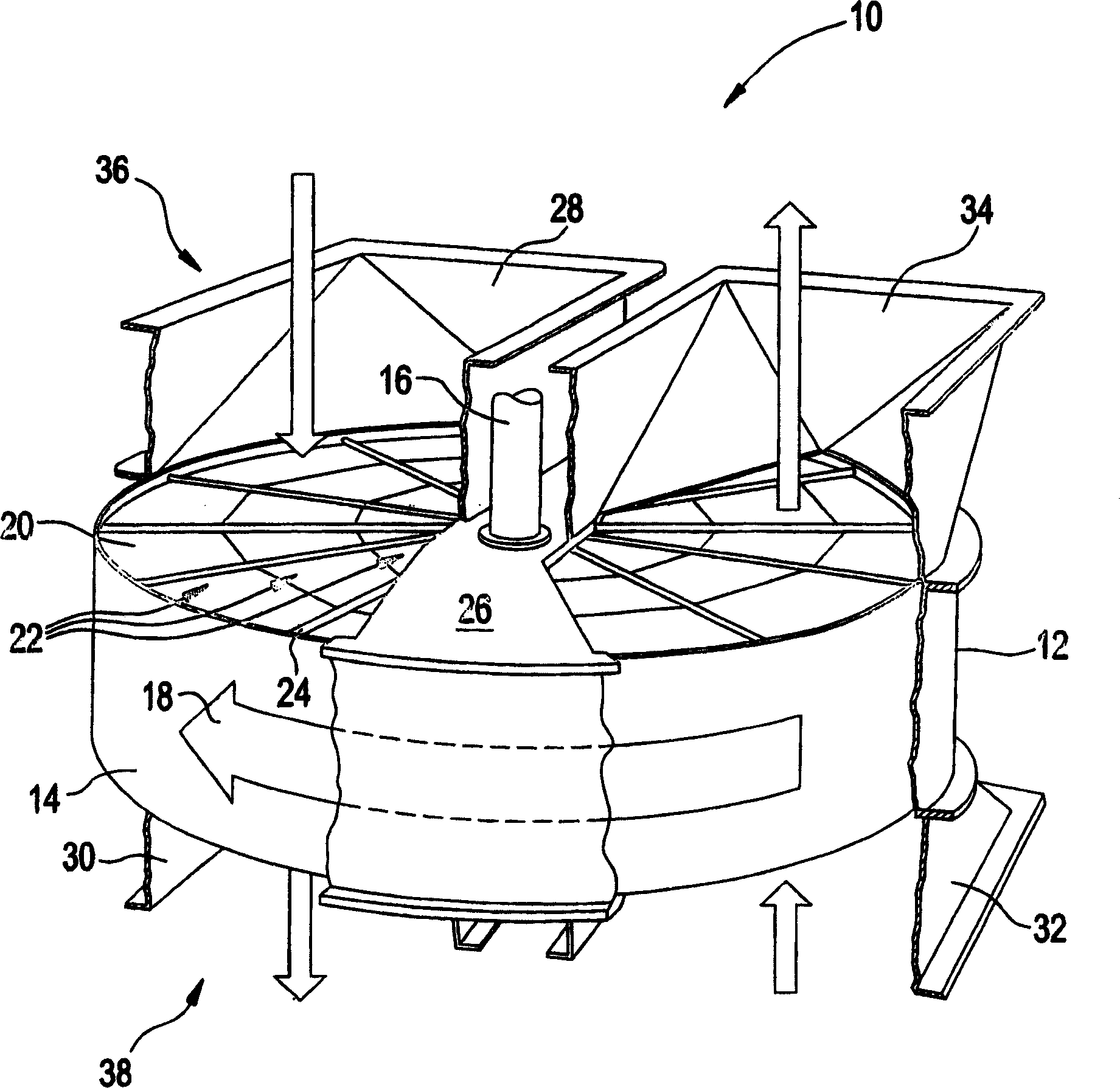

[0027] 1 is a perspective view, partially broken away, of a conventional air preheater 10 showing a housing 12 in which a rotor 14 is mounted on a drive shaft or column 16 for rotation in the direction indicated by arrow 18 . The wheel includes a plurality of sectors 20 each containing a plurality of blue frame modules 22 and each sector is defined by a partition 24 . The blue frame module 22 includes heat exchange surfaces. The housing 12 is divided into a flue gas side and an air side by means of a flow-tight sector plate 26 . The corresponding sector plate is also located at the bottom of the unit. The hot flue gas enters the air heater through the gas inlet duct 28 , flows through the rotor 14 where heat is transferred to the blue frame module 22 and then exits through the gas outlet duct 30 . Simultaneously flowing air enters through the air inlet duct 32 , flows through the blue frame module 22 where it gains heat and then exits through the air outlet duct 34 . The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com