Centrifugal pump

A centrifugal pump and pump body technology, applied in the field of centrifugal pumps, can solve problems such as low operating efficiency, increased friction surface, increased friction loss, etc., and achieve the effects of improving operating efficiency, increasing vacuum degree, and increasing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

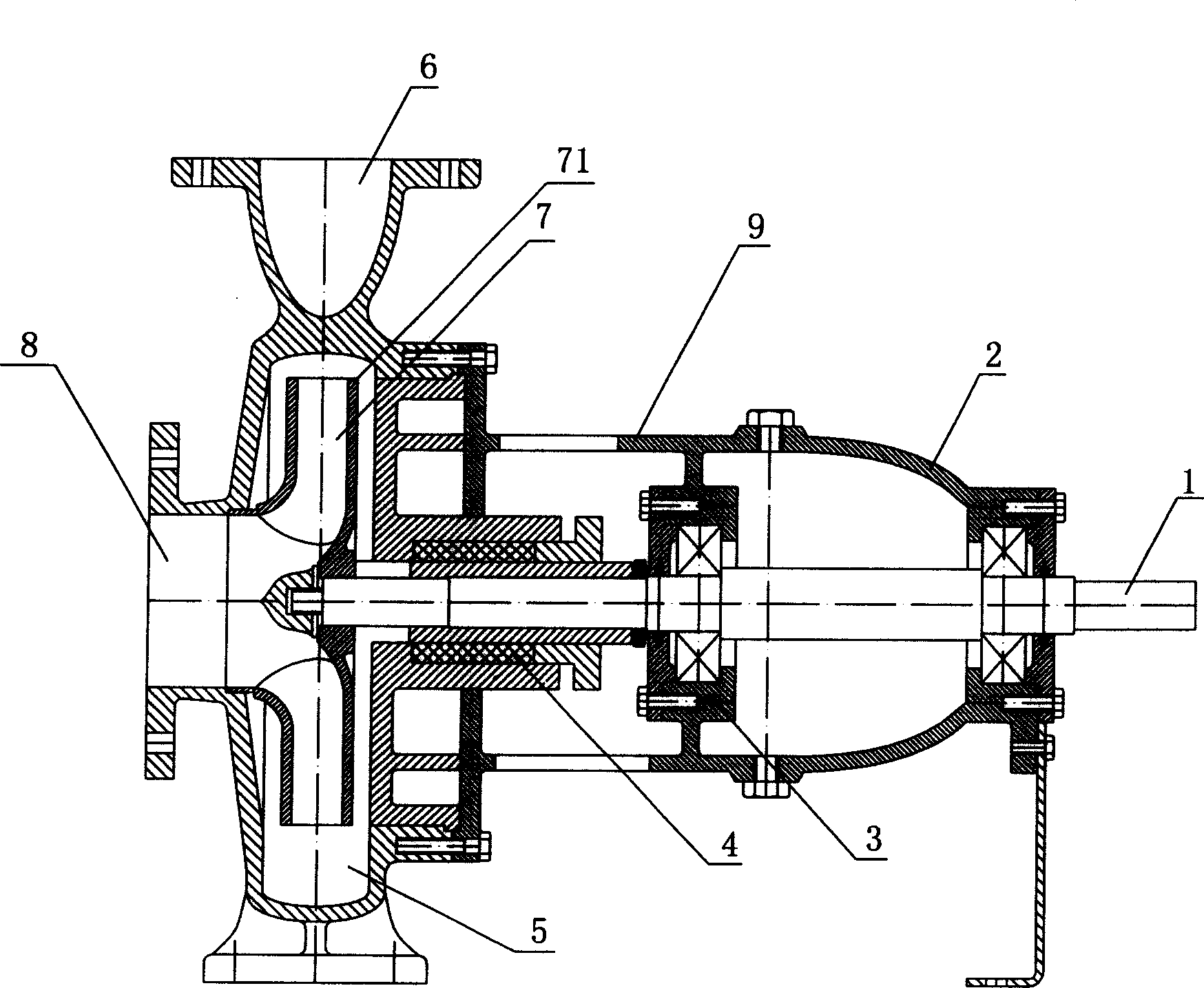

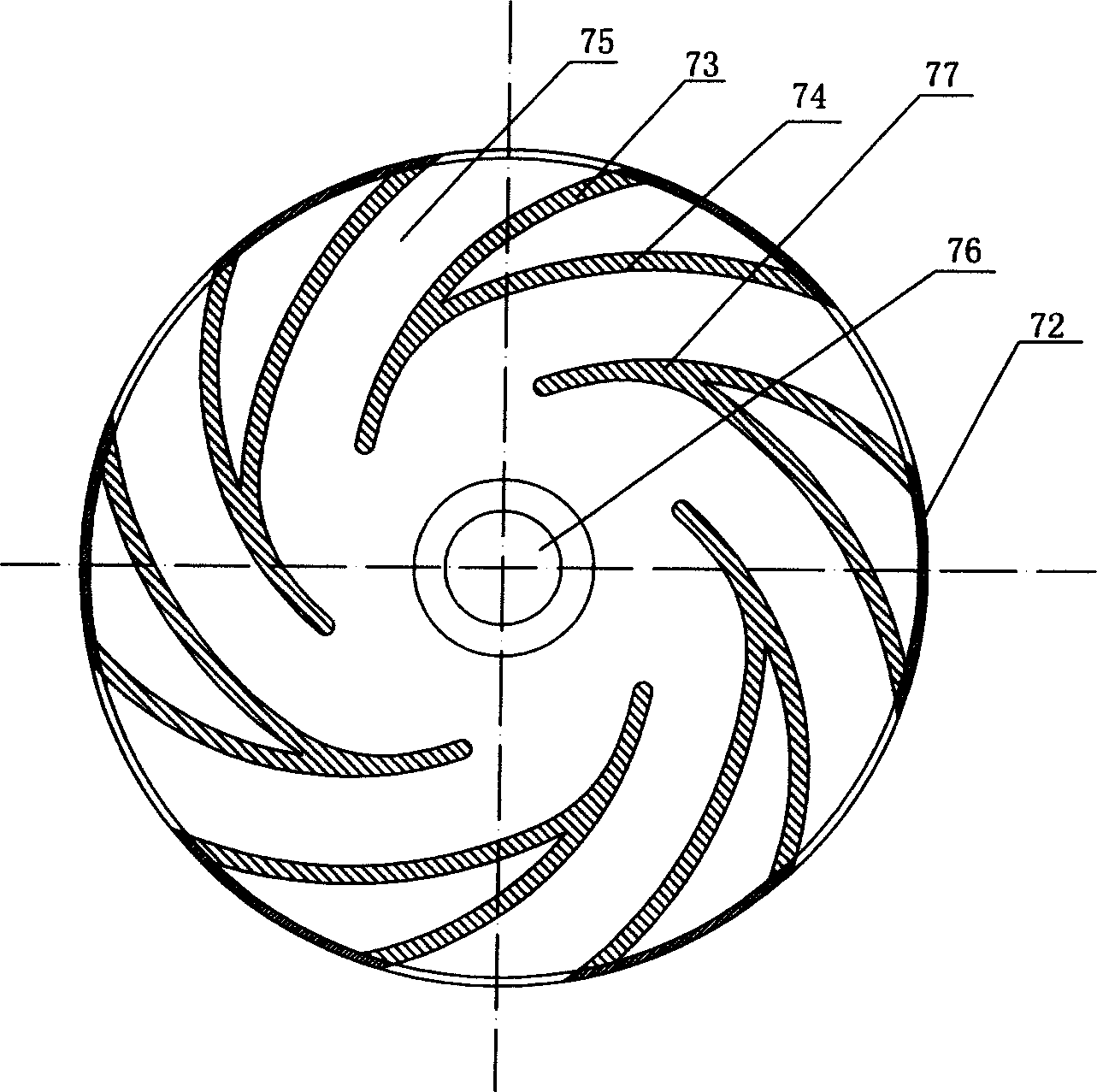

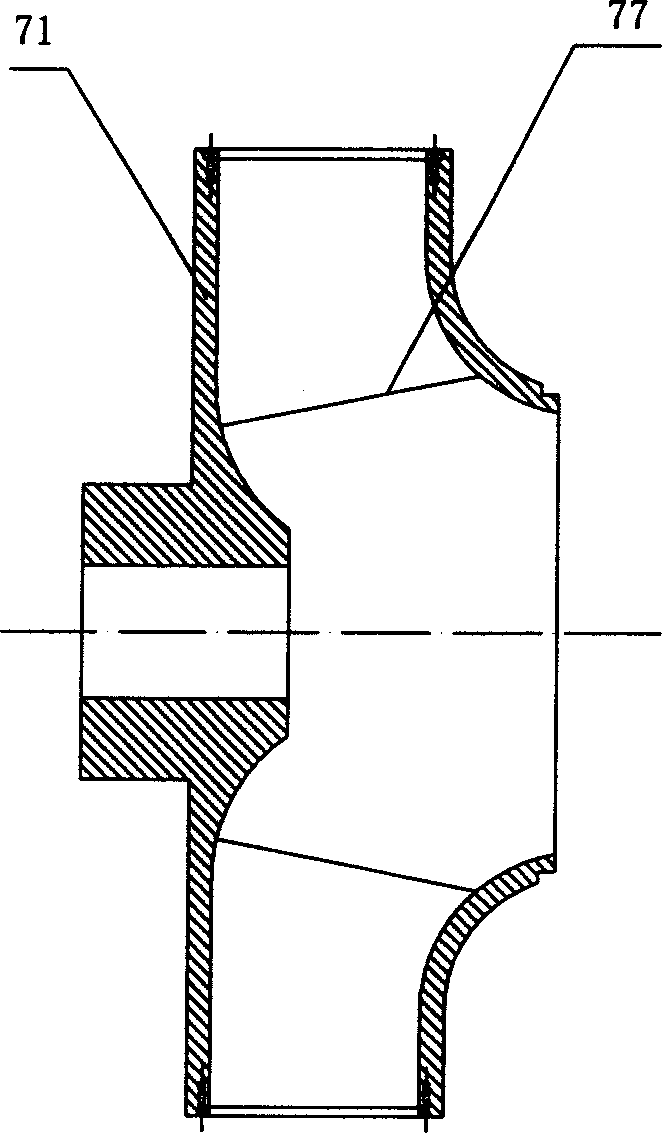

[0032] Such as figure 1 , figure 2 and image 3 As shown, the centrifugal pump of the present invention comprises a pump body 9, a pump shaft 1 and an impeller 7, and the inside of one end of the pump body 9 is cavity-shaped to form a volute 5, and the volute 5 passes through the flow channel 75 of the impeller 7 and the pump The water inlet 8 opened on the body 9 communicates with the water outlet 6. The other end of the pump body 9 is equipped with a pump shaft 1. The pump shaft 1 is fixed in the pump body 9 through the bearing seat 2 and the bearing 3, and is sealed by the sealing layer 4. It is separated from the volute 5 at the other end in the pump body 9 to prevent water from flowing in. The impeller 7 is arranged in the volute 5 of the pump body 9 and installed on the pump shaft 1. The impeller 7 includes a wheel casing 76, a web 71 and two or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com