Drum type shift printing machine in use for board press in large area

A lithographic and roller-type technology, applied in printing presses, rotary printing presses, gravure rotary printing presses, etc., can solve the problems of low printing quality, uneven contact surface contact, unsuitable for large-area workpiece printing, etc. Uniform, high working efficiency and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

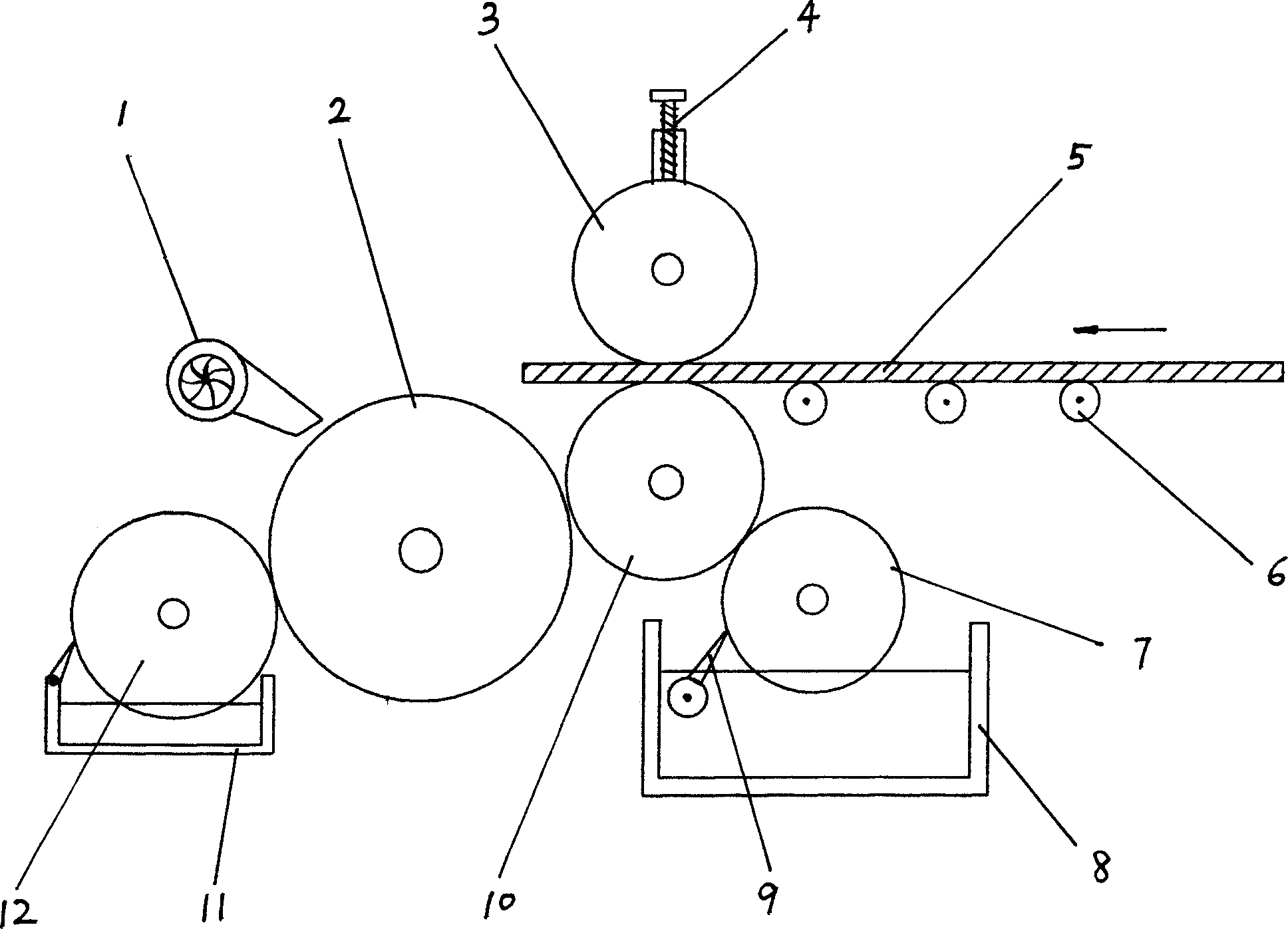

[0011] For simplification, the frame and driving device are omitted in the drawings.

[0012] Referring to the accompanying drawings, the drum type pad printing machine of the embodiment includes a printing plate, a pad printing intermediate, a driving device, and a frame, wherein the printing plate 7 adopts a roller gravure, the pad printing intermediate 10 adopts a flexible roller, and the printing plate 7 and the pad printing intermediate body 10 are driven by gear meshing to ensure the synchronization between the two and prevent relative sliding from affecting the printing quality.

[0013] Next to the pad printing intermediate 10, there is a waste ink removal roller 2, which is in close contact with the pad printing intermediate 10, and is driven by gear engagement to absorb the ink on the pad printing intermediate 10 when there is no workpiece or a gap between the workpieces, so as to prevent Overlapping ink blots appear on the pad printing intermediate 10 .

[0014] An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com