Lithium ion battery pole piece coating method and coating machine

A lithium-ion battery and coating method technology, which is applied to battery electrodes, devices for coating liquid on surfaces, circuits, etc. The effect of stability, avoidance of spacing changes, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

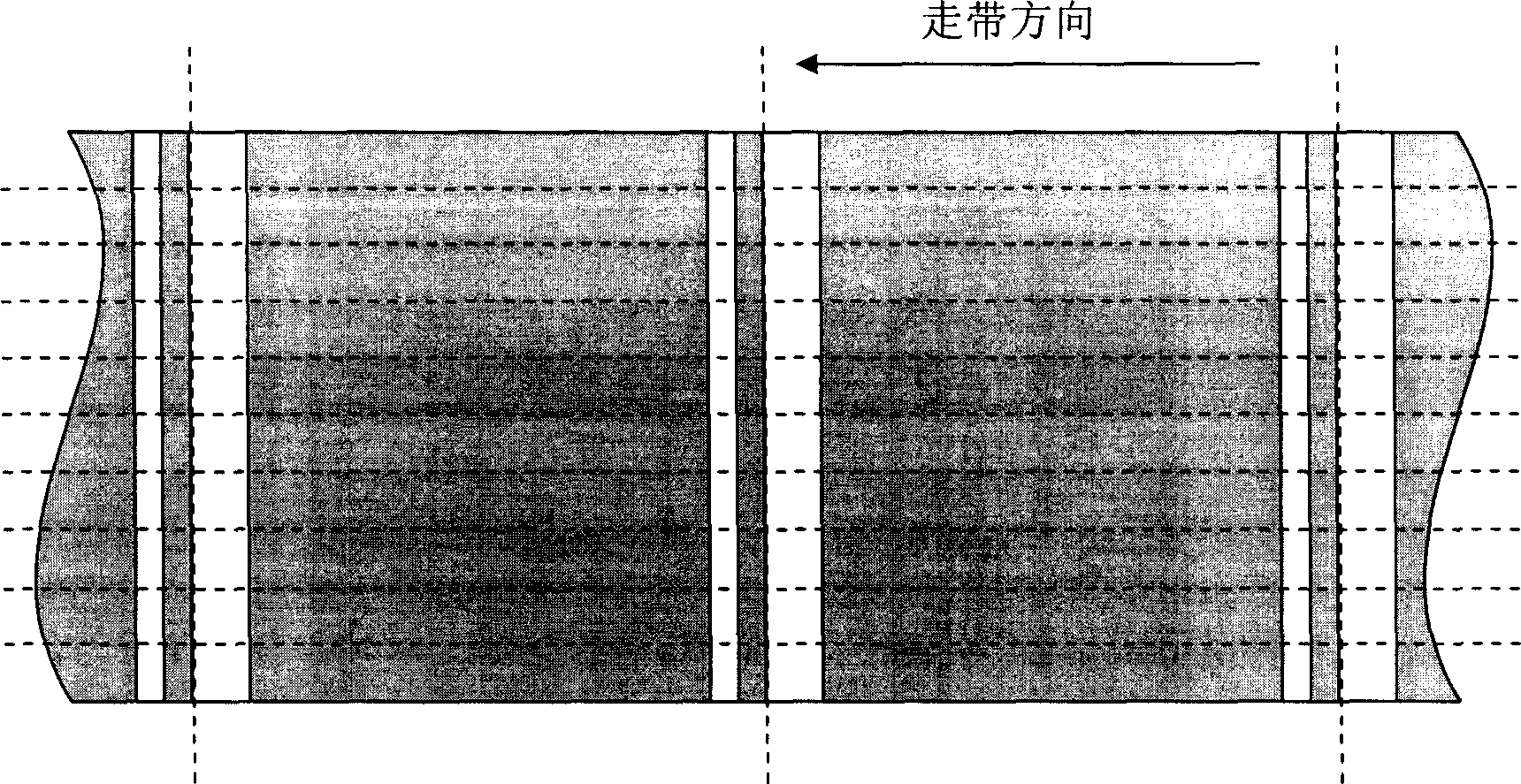

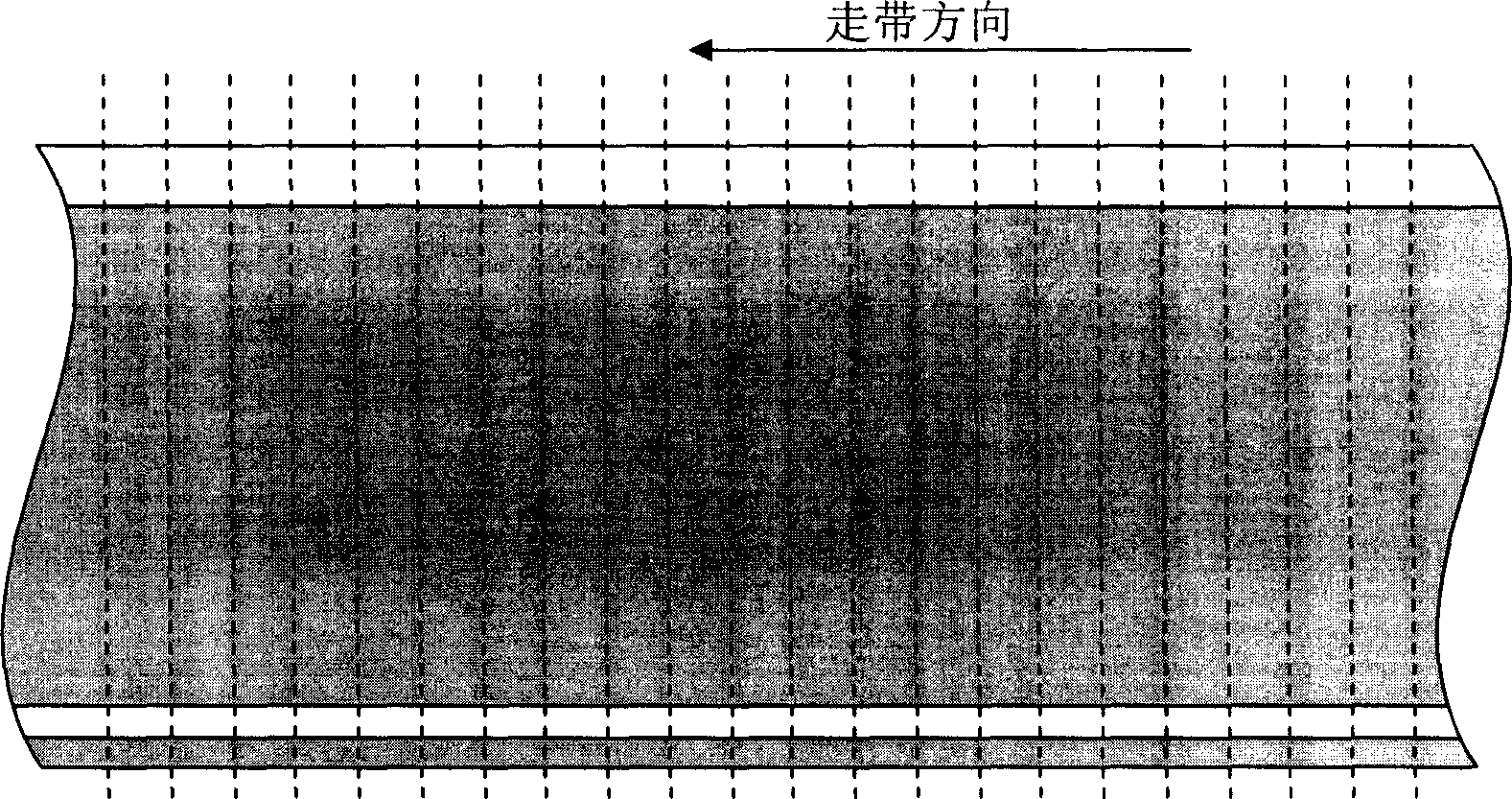

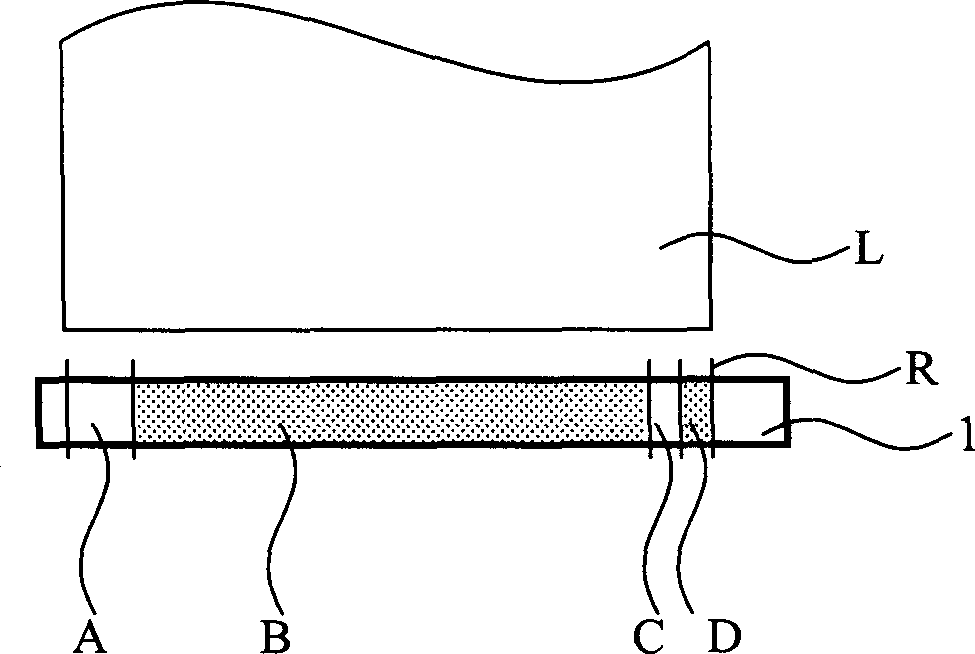

[0016] The invention provides a method that can not only carry out continuous coating but also produce automatic blanking (that is, some places on the surface of the current collector of the pole piece are not coated with active materials) in the coating process of the pole piece of the lithium battery. The key point is to change the operation mode of the conventional "transverse coating" (that is, the blank area is parallel to the coating width direction and perpendicular to the tape running direction), so that the blank area is automatically generated by the non-material section on the machine head, and Extends in the direction of the foil strip. The technical scheme adopted in the present invention is that, in the width direction of the coating machine head, the dressing section and the material-free section are arranged at intervals according to the design parameters of the pole piece, and the foil belt is put into the machine and started to coat continuously, so as to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com