Fluid mixer

A fluid mixing and fluid technology, applied in fluid mixers, mixers, mixing methods, etc., can solve the problems of lower mixing ratio accuracy, inability to mix ratio mixing, and lower mixing ratio accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings, but it is obvious that the present invention is not limited thereto.

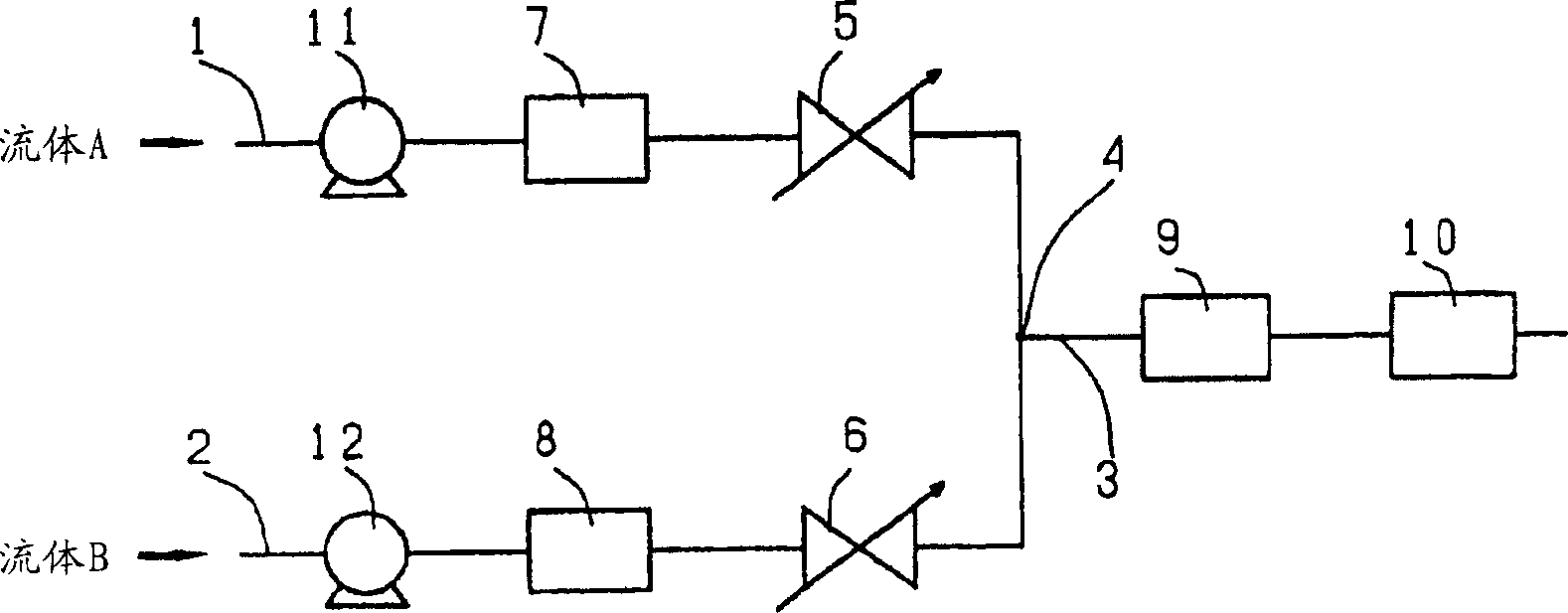

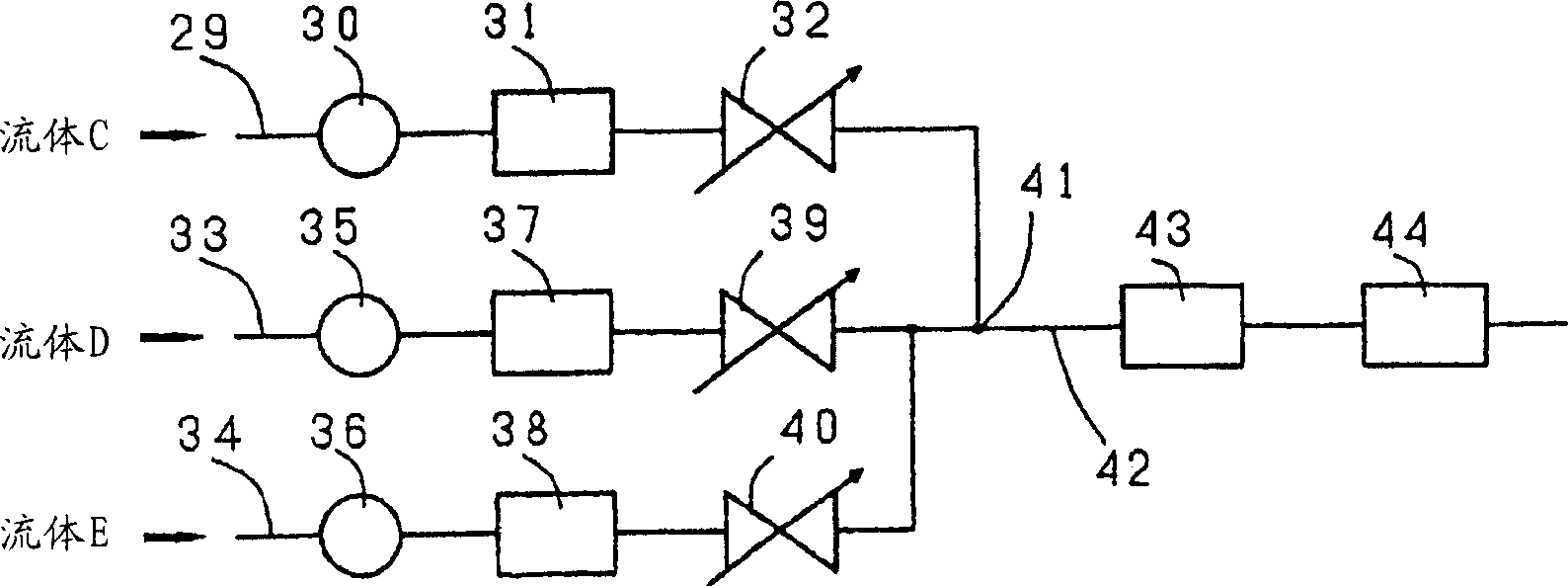

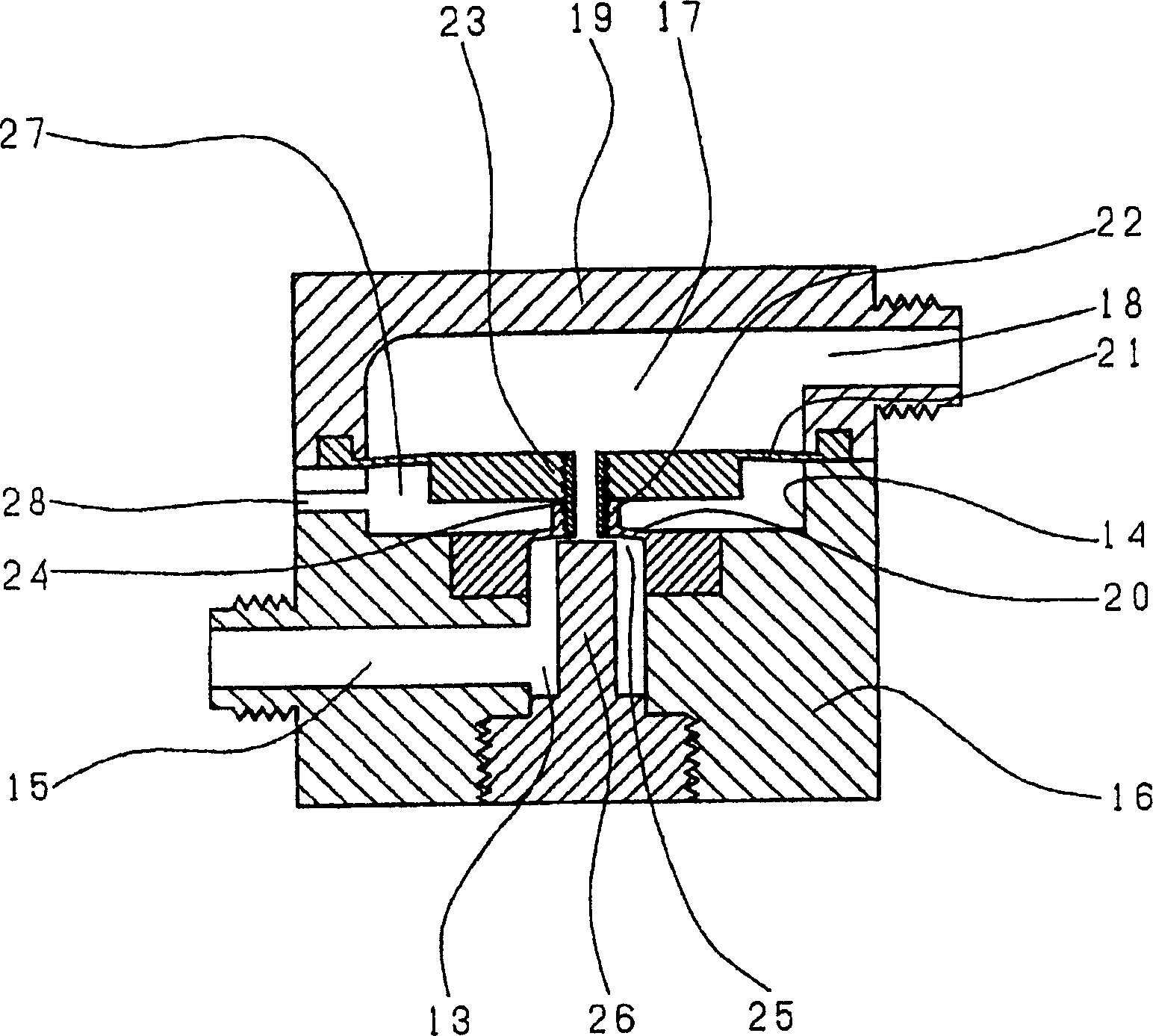

[0019] The first embodiment of the present invention refers to figure 1 , image 3 illustrate. Reference numeral 1 is a first supply line through which fluid A flows, and a pump 11, a pressure reducing valve 7, and a needle valve 5 as a throttling portion are arranged in series from the upstream side; reference numeral 2 is a second supply line through which fluid B flows, Similar to the first supply line 1 , the pump 12 , the pressure reducing valve 8 , and the needle valve 6 as a throttling portion are arranged in series from the upstream side. Reference numeral 4 is a confluence junction in the device, which is a position where the quantitatively supplied fluids A and B merge. Reference numeral 3 is a mixing line, a line on the downstream side below the joining point 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com