Ceramic brick powder lot feeding method and equipment thereof

A technology of feeding equipment and ceramic powder, which is applied in the field of ceramic tile production, can solve the problems of rigid pattern, lack of transitional changes in texture and details, and difficulty in forming fine and stable patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

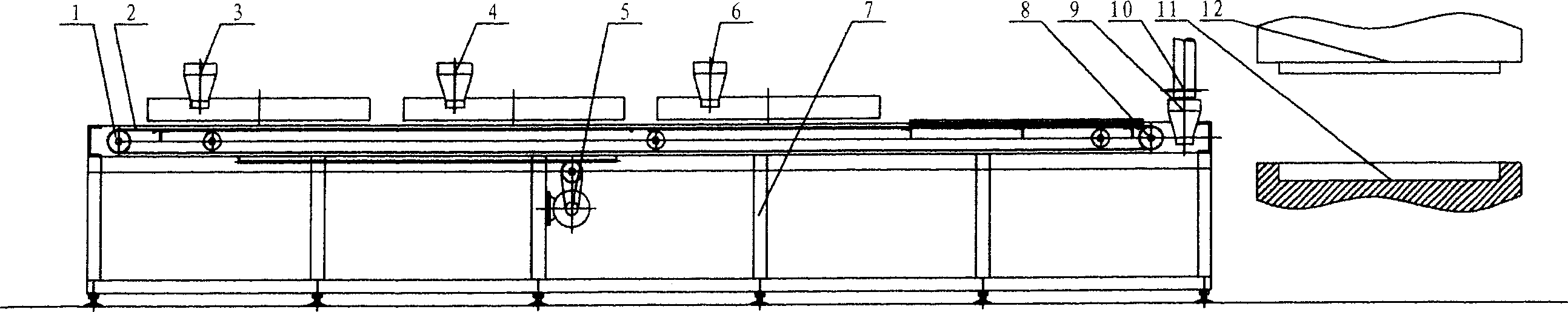

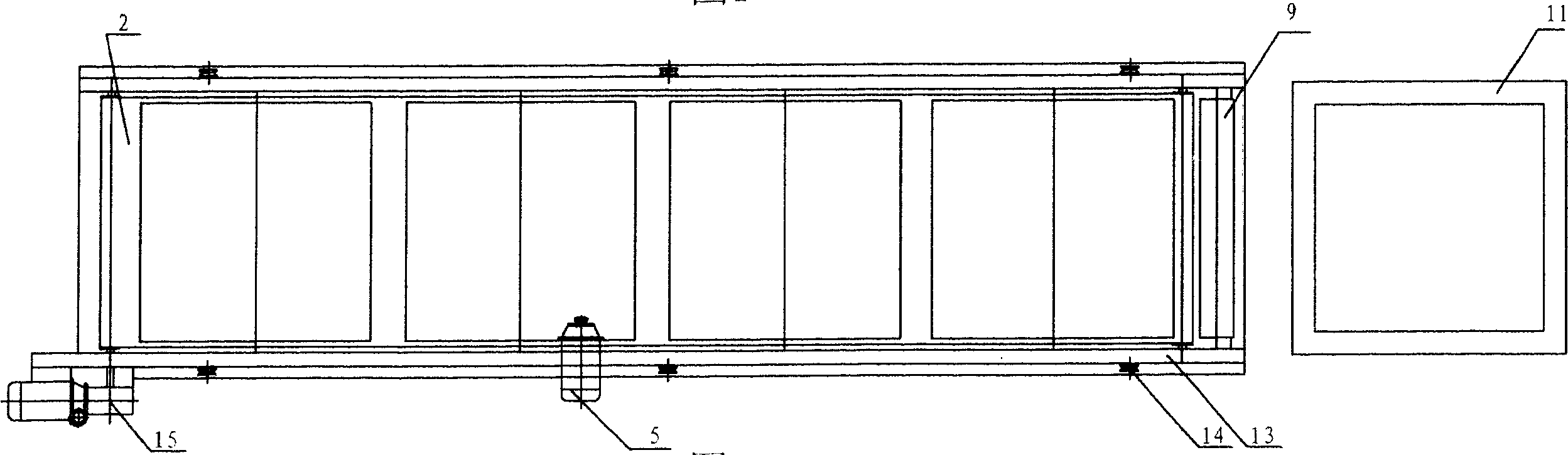

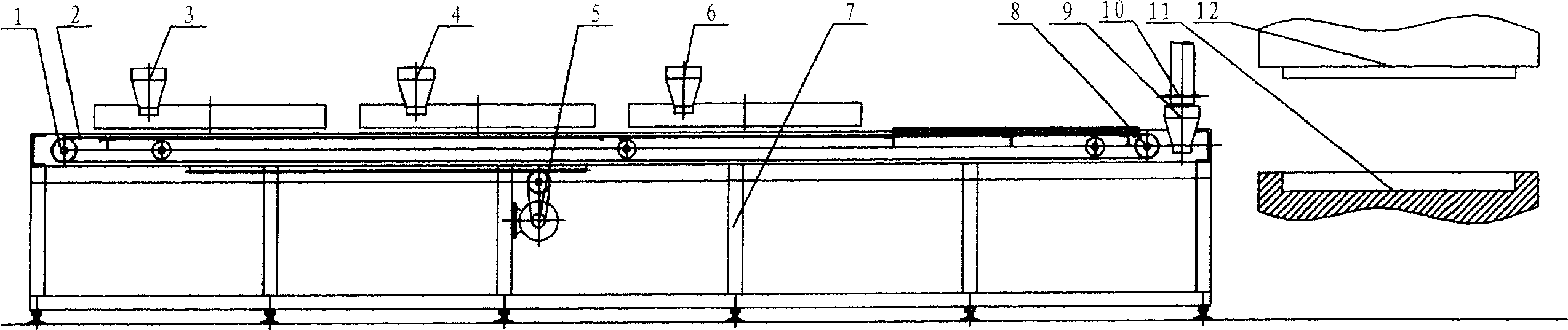

[0026] The ceramic tile powder feeding equipment of the present invention includes a mixing device, a fixed frame 7, a horizontal driving device 5, a powder conveying device, and a distribution hopper 9. The mixing device can be various known distribution devices, including at least one distribution station, can be a multi-tube distribution device, can also be a positioning distribution device, or can be any other distribution device. The powder conveying device consists of a conveyor belt 2, a conveyor belt driving roller 1, a conveyor belt passive roller 8, a powder conveying device frame 13, and a conveyor belt driving device 15. The conveyor belt driving roller 1 and the conveyor belt passive roller 8 are arranged on the conveyor belt. At both ends of the belt 2, the conveyor belt driving device 15 is connected with the conveyor belt driving roller 1, and the conveyor belt driving roller 1 is started, and the conveyor belt starts to circulate, and the powder is distributed ...

Embodiment 2

[0028] The ceramic tile powder feeding equipment of the present invention includes a mixing device, a fixed frame 7, a horizontal driving device 5, a powder conveying device, and a distribution hopper 9. The mixing device can adopt various known distributing devices, including at least one distributing station, which can be multi-pipe distributing, positioning distributing, or any other distributing device. The powder conveying device is composed of a conveyor belt 2, a conveyor belt driving roller 1, a conveyor belt passive roller 8, a powder conveying device frame 13, and a conveyor belt driving device 15. When the conveyor belt driving roller 1 is started, the conveyor belt starts to circulate, and the The powder is distributed on the conveyor belt 2 according to a predetermined pattern, and the conveyor belt 2 stops moving. Simultaneously, material pipe 10 supplements bottom material in distribution hopper 9. Such as Figure 7 As shown; start the horizontal drive device ...

Embodiment 3

[0030] The ceramic tile powder feeding equipment of the present invention includes a mixing device, a fixed frame 7, a horizontal driving device 5, a powder conveying device, and a distribution hopper 9. The mixing device can be various known distribution devices, including at least one distribution station, can be a multi-tube distribution device, can also be a positioning distribution device, or can be any other distribution device. The powder conveying device is composed of a conveyor belt 2, a conveyor belt driving roller 1, a conveyor belt passive roller 8, a powder conveying device frame 13, and a conveyor belt driving device 15. When the conveyor belt driving roller 1 is started, the conveyor belt starts to circulate, and the The powder is distributed on the conveyor belt 2 according to a predetermined pattern, and the conveyor belt 2 stops moving. Simultaneously, the feed pipe 10 replenishes the glass-ceramic granular material in the distribution hopper 9 . Start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com