A four-bar type rubber fertilizer applicator

A fertilizer applicator and a four-bar mechanism technology, applied to fertilization devices, planting methods, agricultural machinery, etc., can solve problems such as low work efficiency, weak water and fertilizer retention functions, and high ditching costs, so as to reduce height and labor costs The effect of fat intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

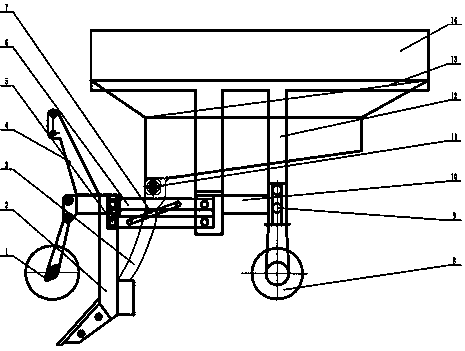

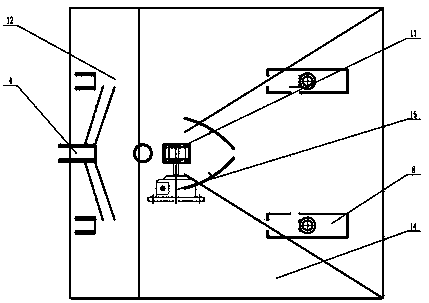

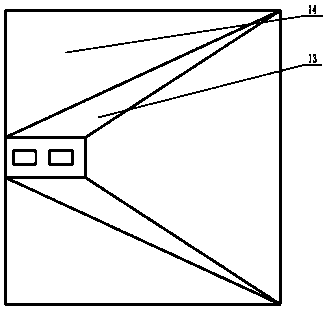

[0033] Such as Figures 1 to 3 Shown is a schematic structural view of a specific embodiment of a four-bar rubber fertilizer applicator of the present invention. see Figures 1 to 3 A four-bar type rubber fertilizer applicator in this specific embodiment specifically includes:

[0034] Fertilizer bucket 14, lower fertilizer pipe 7, frame 10, ground wheel 8, four-bar mechanism 6, suspension mechanism 4, soil / grass pulling mechanism 1, ditching plow 2, both ends of four-bar mechanism 6 are connected to the machine through hinge device 5 The front end of the frame 10 and the suspension mechanism 4, the suspension mechanism 4 installs the soil / grass mechanism 1 and the ditching plow 2, wherein the soil / grass mechanism 1 is located at the front end of the ditching plow 2; the ground wheel 8 is installed on the frame 10 Tail end, fat bucket 14 is installed on the frame 10, and the bottom of fat bucket 14 is communicated with lower fertilizer pipe 7, and the lower end of lower fert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com