Uses of electric membrane adjusting valve in hydrogen production plant

A hydrogen production device and regulating valve technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of increasing the overall structure of the equipment, increasing the source of failure, etc., and achieve the effects of improving reliability, stabilizing electrical signals, and facilitating high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

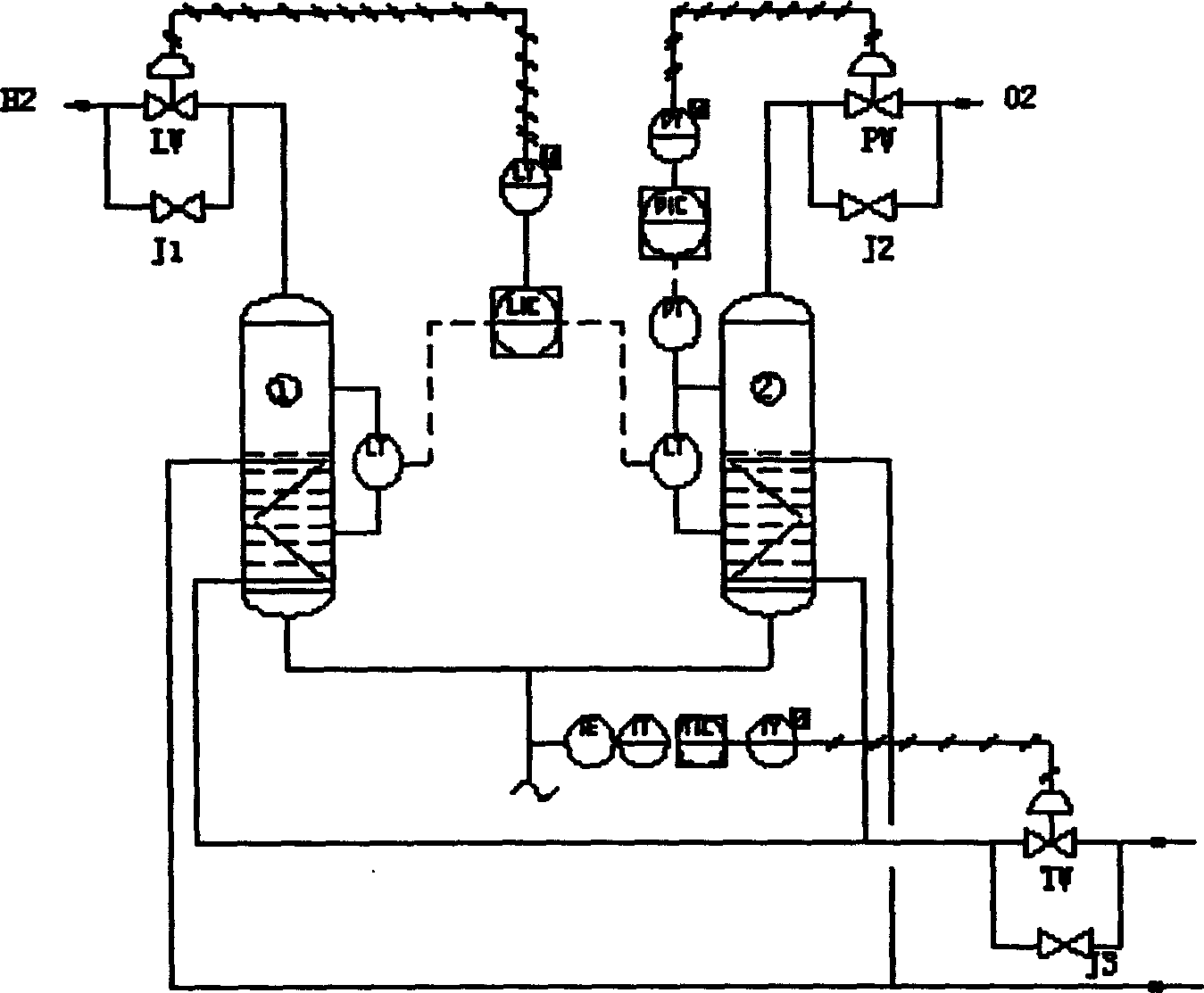

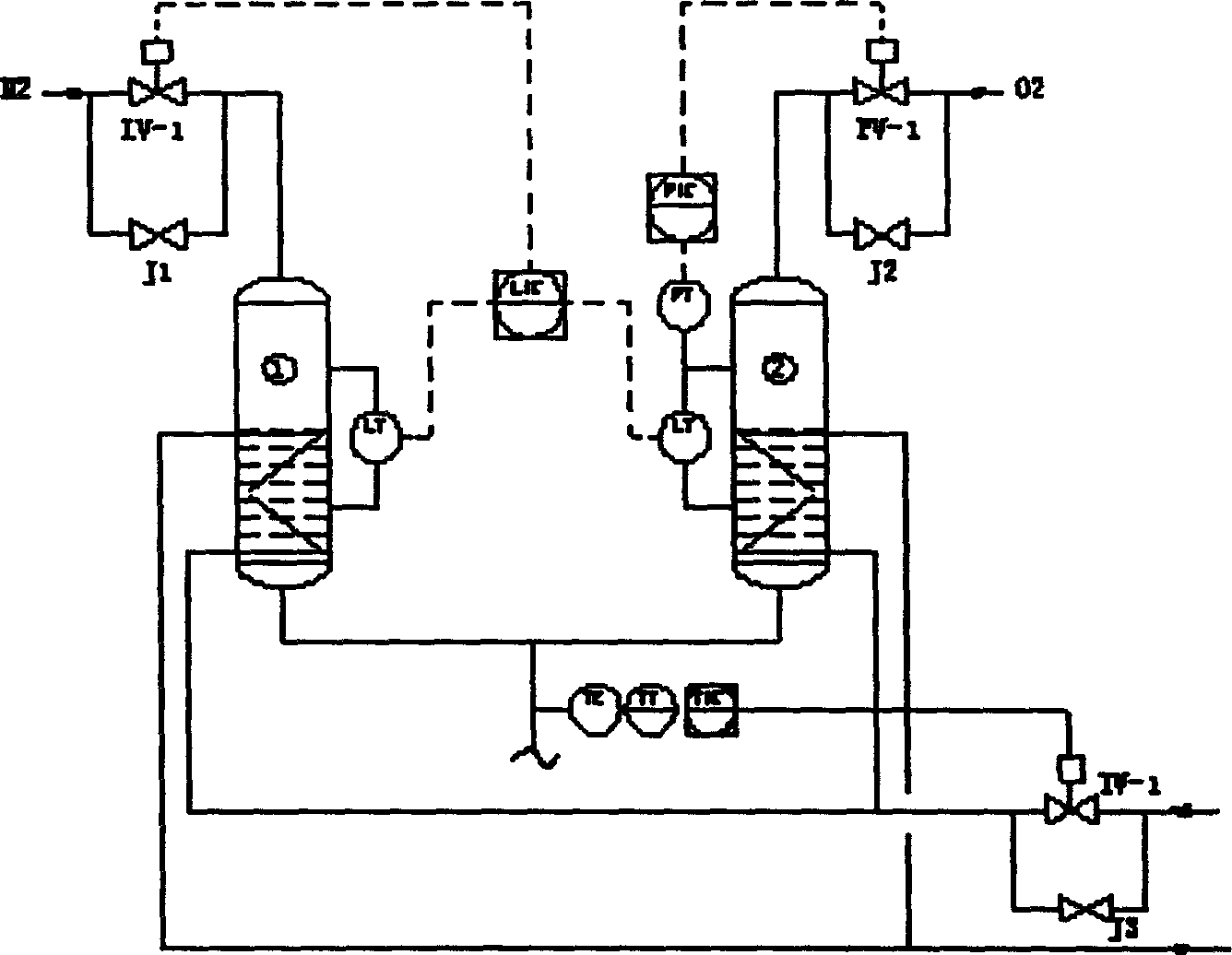

[0010] like figure 2 As shown, in the picture: 1- Hydrogen separator, 2- Oxygen separator, 3- Liquid level electric membrane regulating valve, 4- Pressure electric membrane regulating valve, 5- Temperature electric membrane regulating valve, LT- Liquid level transmitter , PT-pressure transmitter, TE-platinum resistance, TT-temperature transmitter, J1-liquid level bypass valve, J2-pressure bypass valve, J3-temperature bypass valve.

[0011] The liquid level pneumatic film control valve LV, pressure pneumatic film control valve PV, and temperature pneumatic film control valve TV are respectively liquid level electric film control valve LV-1, pressure electric film control valve PV-1, and temperature electric film control valve. TV-1 replacement.

[0012] A liquid level transmitter LT and a pressure transmitter PT are installed on the hydrogen separator 1 and oxygen separator 2 of the water electrolysis hydrogen production equipment, and a temperature sensor TE is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com