Light guide plate main body, light guide plate, backlight, and liquid crystal display device

A light guide plate and optical component technology, applied in water supply devices, optics, nonlinear optics, etc., can solve the problems of difficult to obtain durable performance, complex structure, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

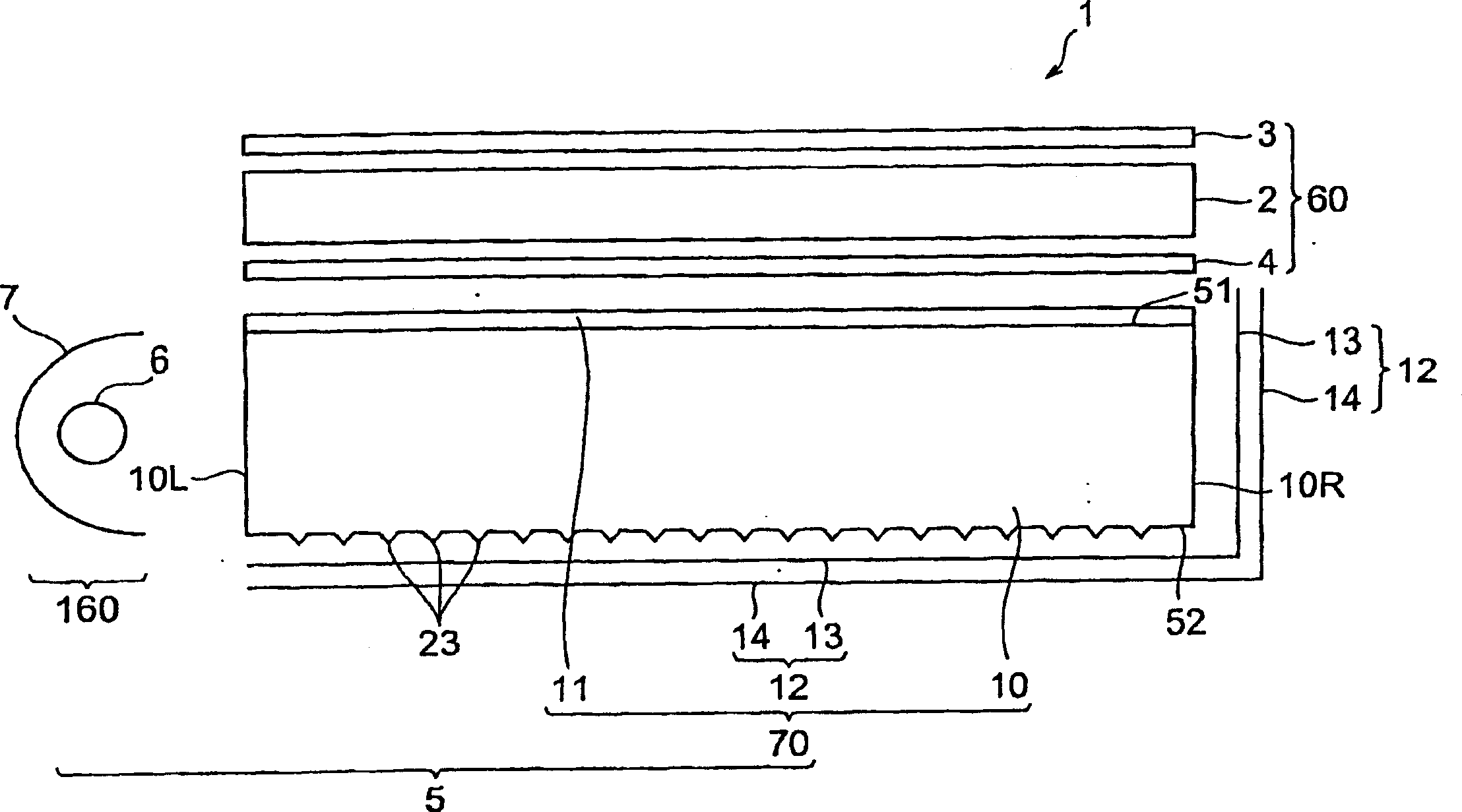

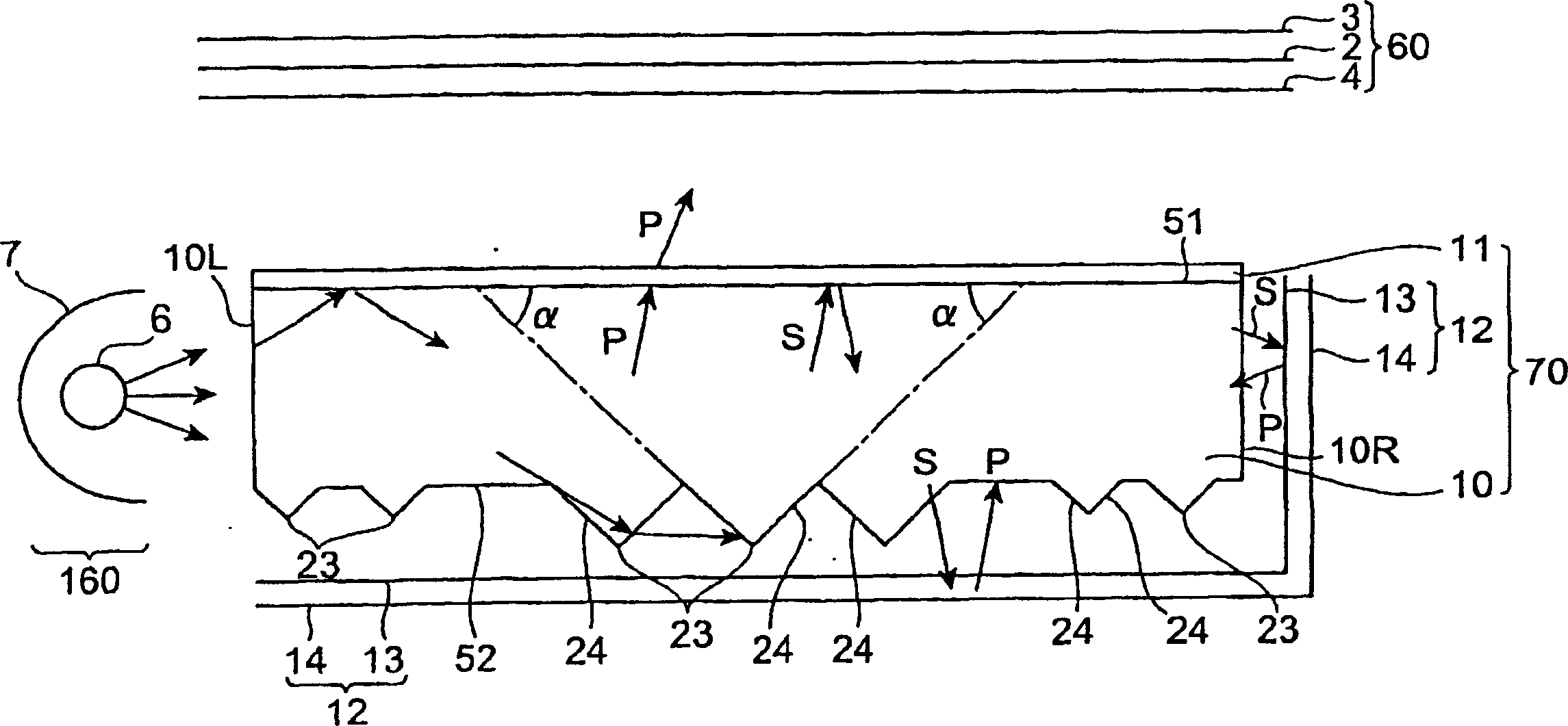

[0063] A liquid crystal display device as an embodiment of the present invention is shown in figure 1 middle. exist figure 1 In , reference numeral 1 denotes a liquid crystal display device. The liquid crystal display device 1 can include a liquid crystal display element 60 , a light guide plate 70 , and a light source unit 160 . The light guide plate 70 and the light source unit 160 constitute an edge-illuminated back-illuminated light module 5 .

[0064] The liquid crystal display element 60 can be composed of a liquid crystal cell 2 and polarizing plates 3 and 4 . Polarizing plates 3 and 4 are disposed on the upper and lower sides of the liquid crystal cell 2, respectively.

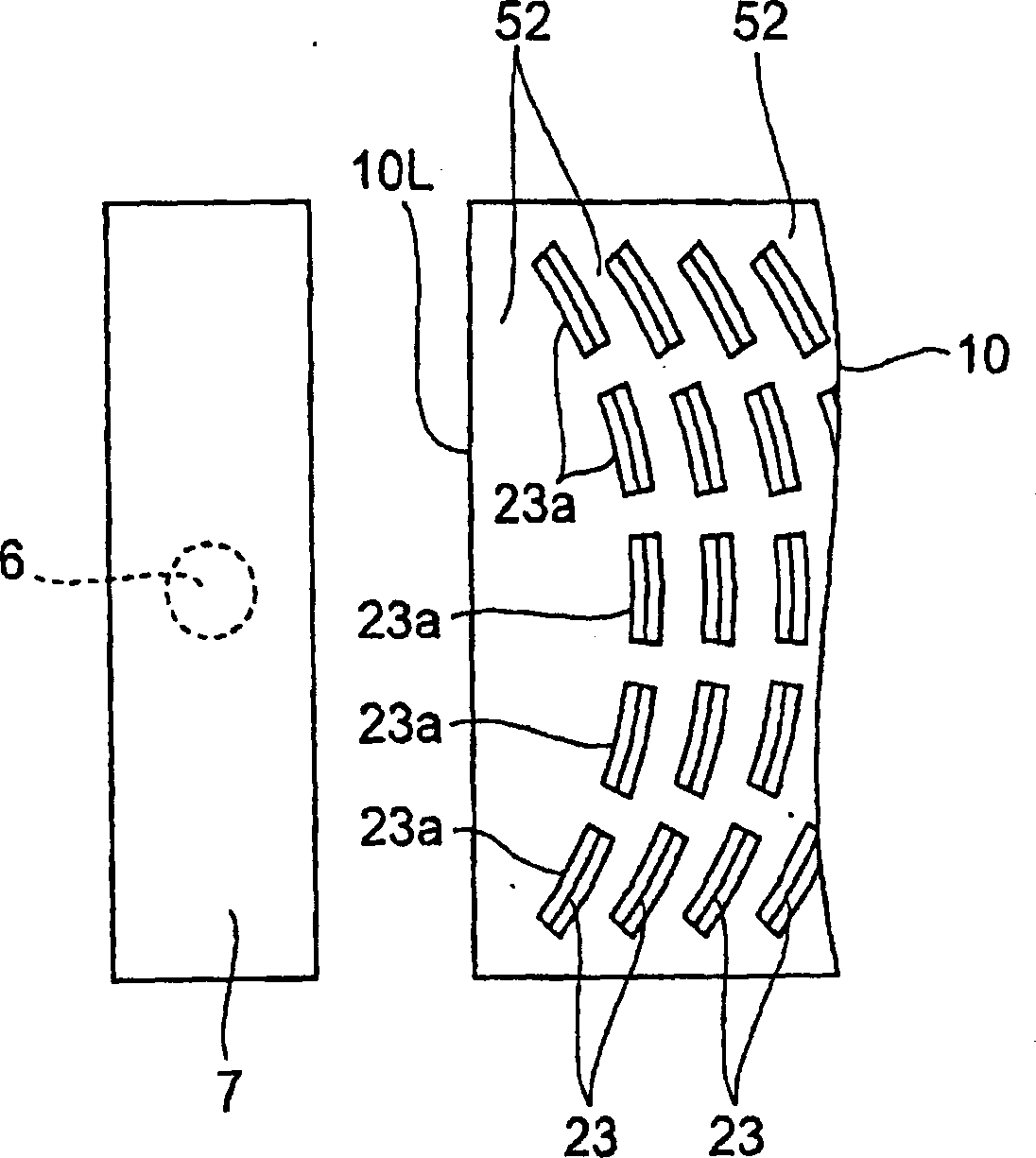

[0065] At the lower surface side of the polarizing plate 4 located on the lower side of the liquid crystal display element 60, a light guide plate 70 is provided. The light guide plate 70 may have a light guide plate main body 10 , a polarization separation component 11 and a polarization direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com