Optical image stabilizer for camera lens assembly

An optical image and stabilizer technology, applied in optics, camera, image communication, etc., can solve the problems that hinder the reduction of the size of the camera lens assembly and the installation of the camera lens assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. For clarity and conciseness, detailed descriptions of well-known functions and constructions are omitted since they would obscure the subject matter of the present invention.

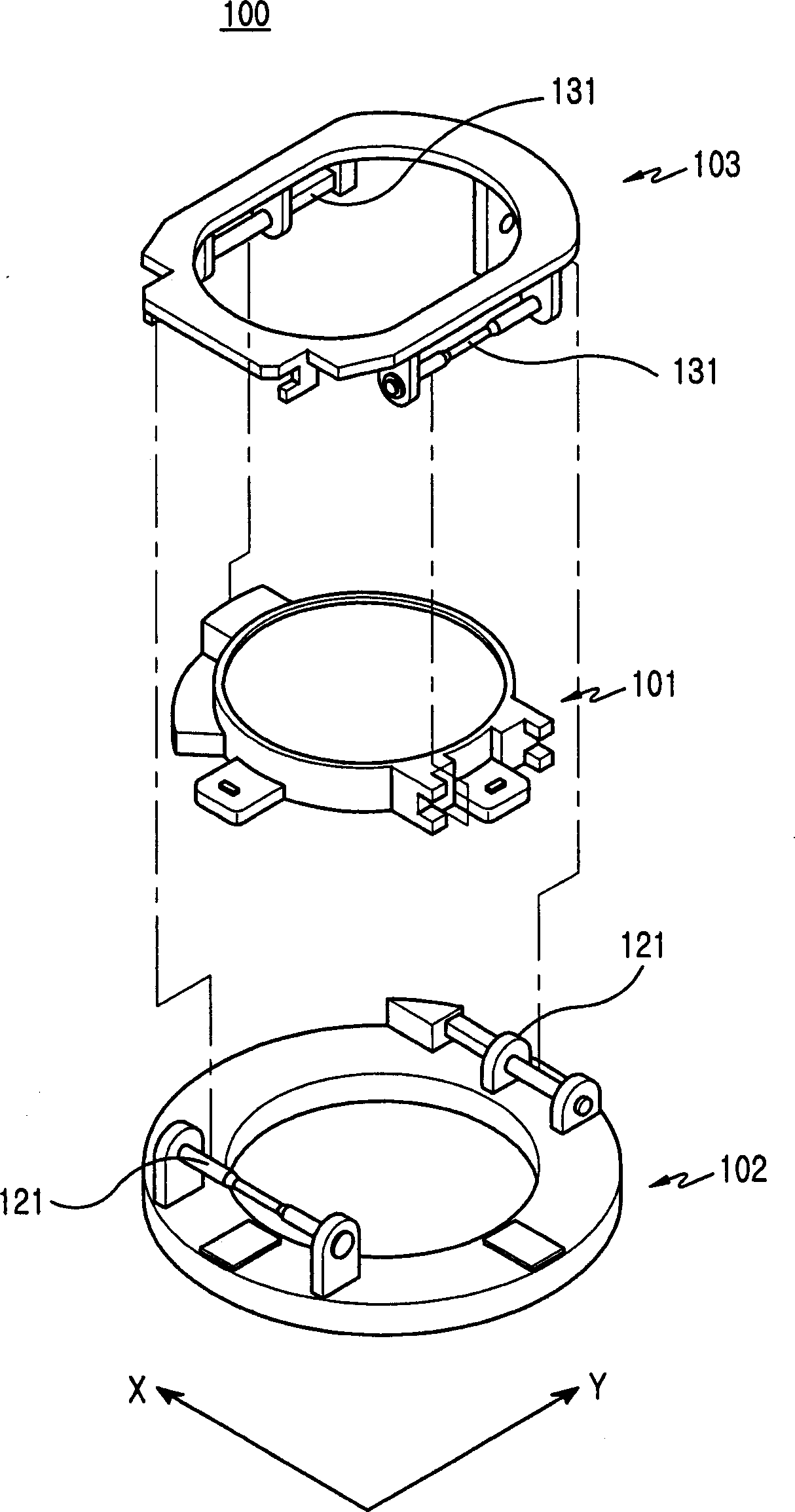

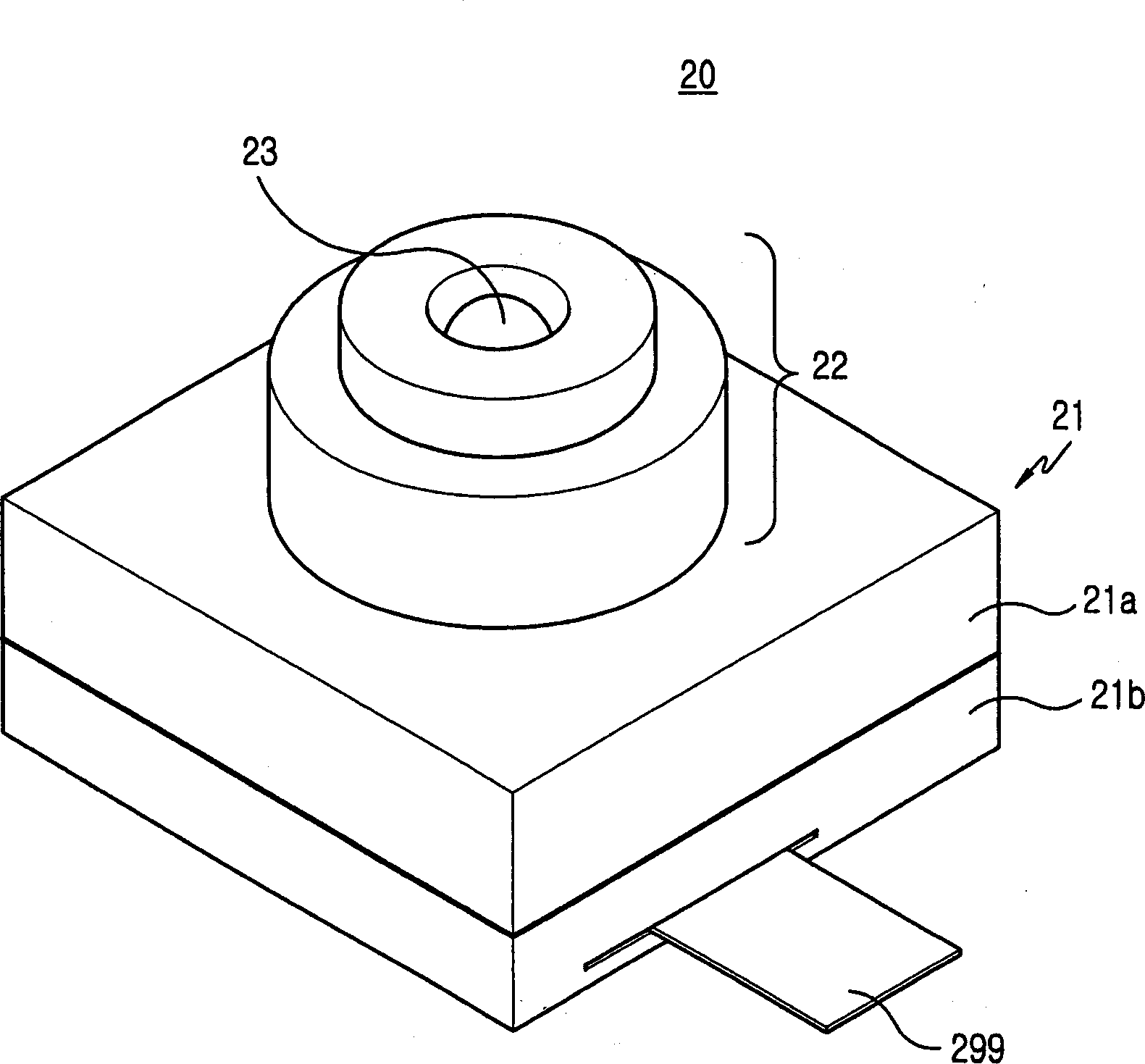

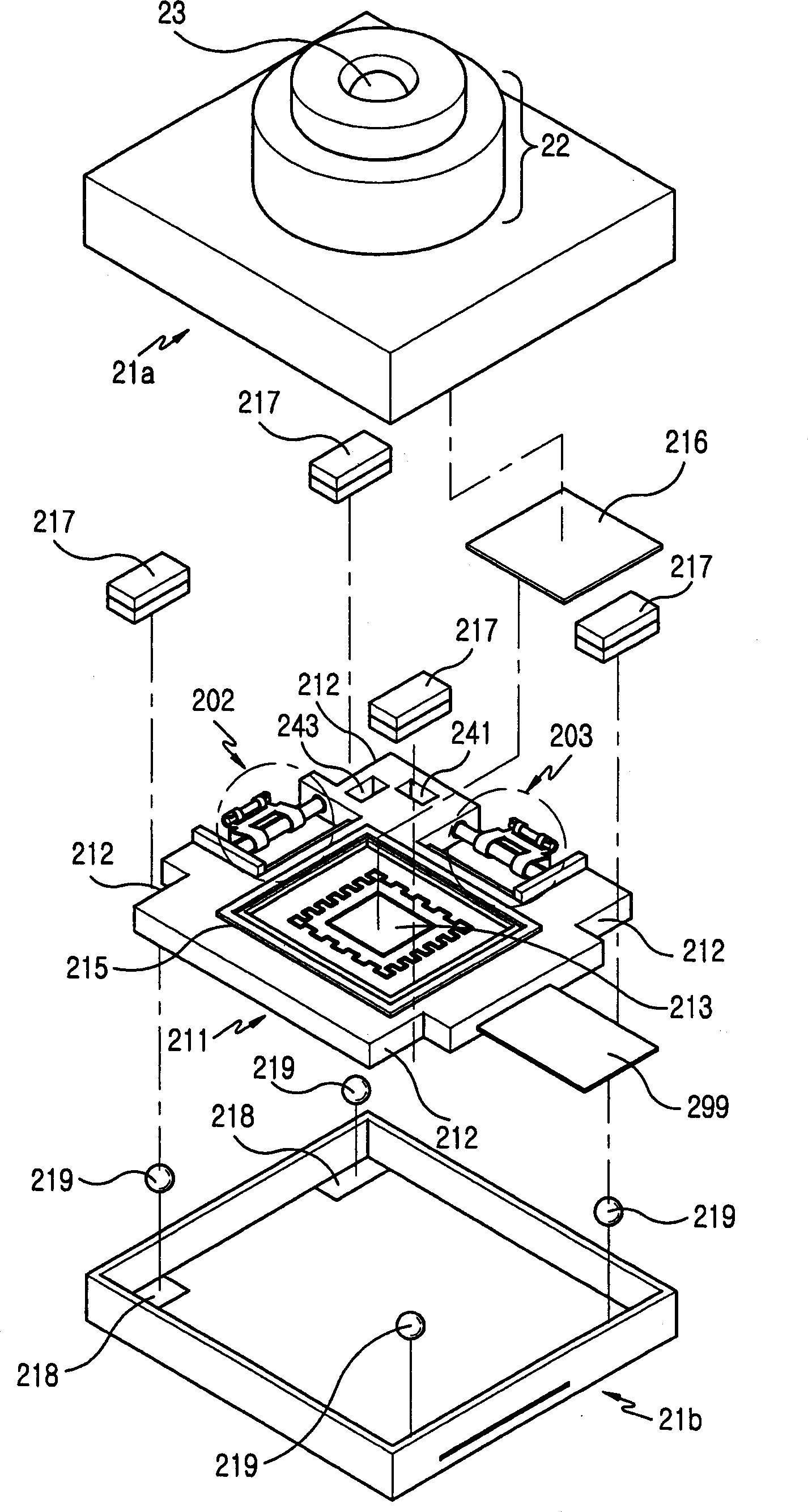

[0032] refer to Figure 2-4 , the optical image stabilizer 200 of the camera lens assembly 20 according to the present invention is provided on the casing 21 , specifically, in the lower casing 21 b of the camera lens assembly 20 . In operation, the optical image stabilizer 200 performs image stabilization by correcting the position of the image sensor 213 according to the shaking of the user's hand.

[0033] The camera lens assembly 20 has a housing 21 including an upper housing 21a and a lower housing 21b, and a light pipe 22 in which at least one lens (not shown) is accommodated. The light pipe 22 extends from the upper housing 21a and has an exposed window 23 on the terminal surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com