Driving apparatus

A technology of driving device and driving shaft, which is applied in the direction of transmission device, friction transmission device, electromechanical transmission device, etc., can solve the problems of unfavorable transportation of heavy objects, increase of cost, and limitation of transmission torque, etc., and achieve simple structure, rotation Torque improvement, the effect of increasing the misalignment limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

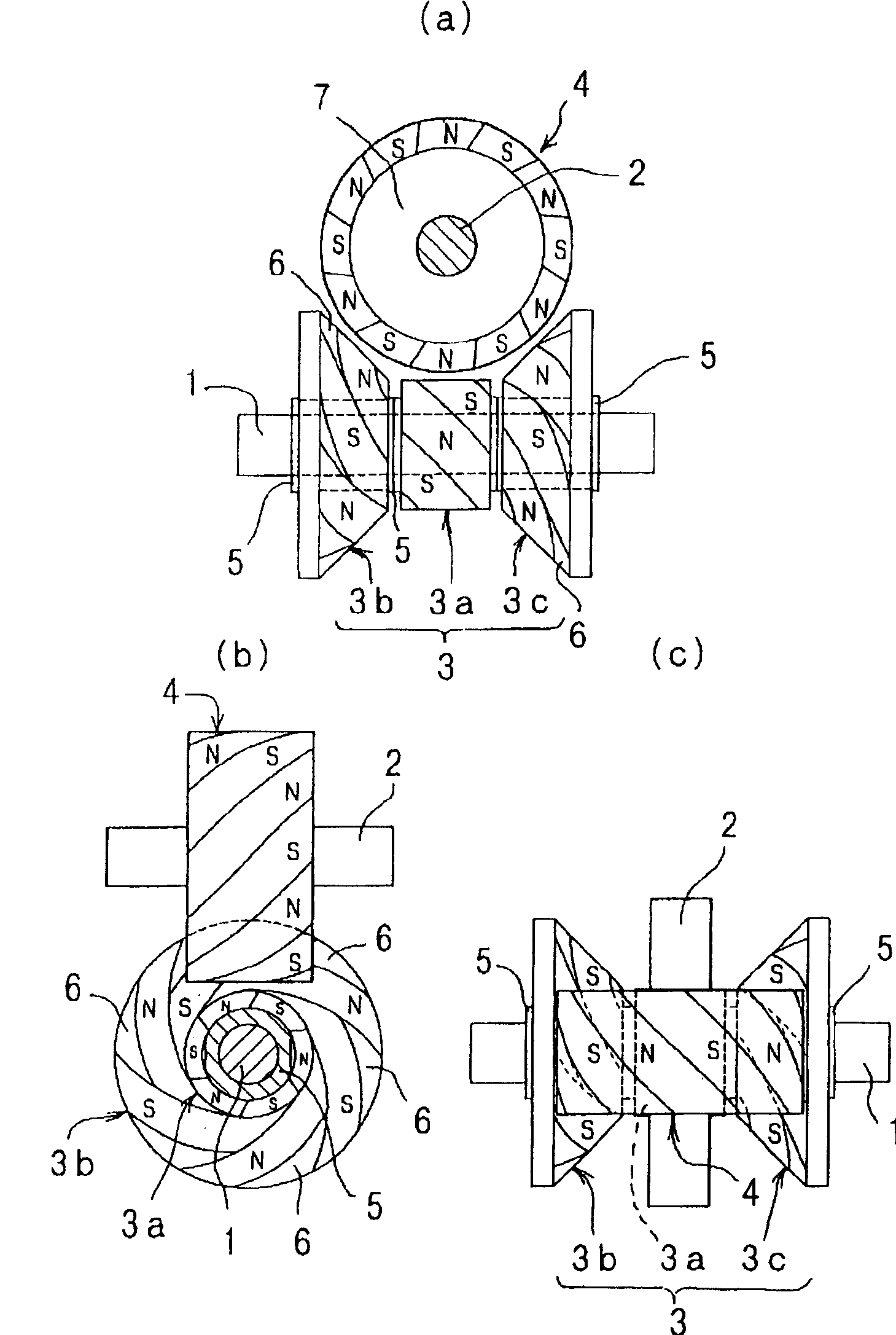

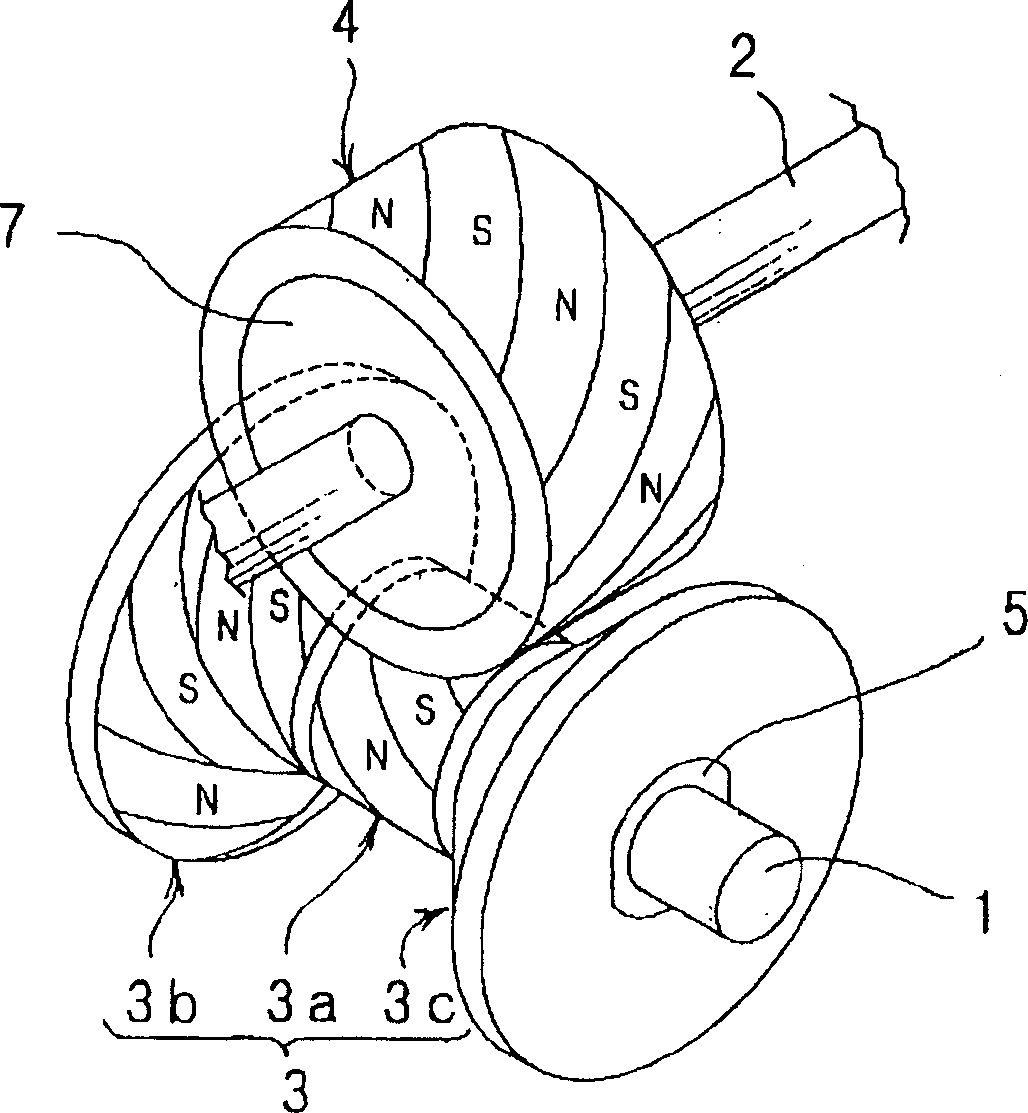

[0041] figure 1 and figure 2The driving device is shown, and the driving device generates magnetic action at three points of the non-contact driving magnetic wheel mounted on the driving shaft with respect to the cylindrical driven magnetic wheel mounted on the driven shaft to perform power transmission, In the figure, symbol 1 is the drive shaft, symbol 2 is the driven shaft arranged at right angles to the above-mentioned drive shaft 1, symbol 3 is the driving magnet wheel fixed on the above-mentioned drive shaft 1, and symbol 4 is fixed on the above-mentioned driven shaft. Driven magnet wheel for axis 2.

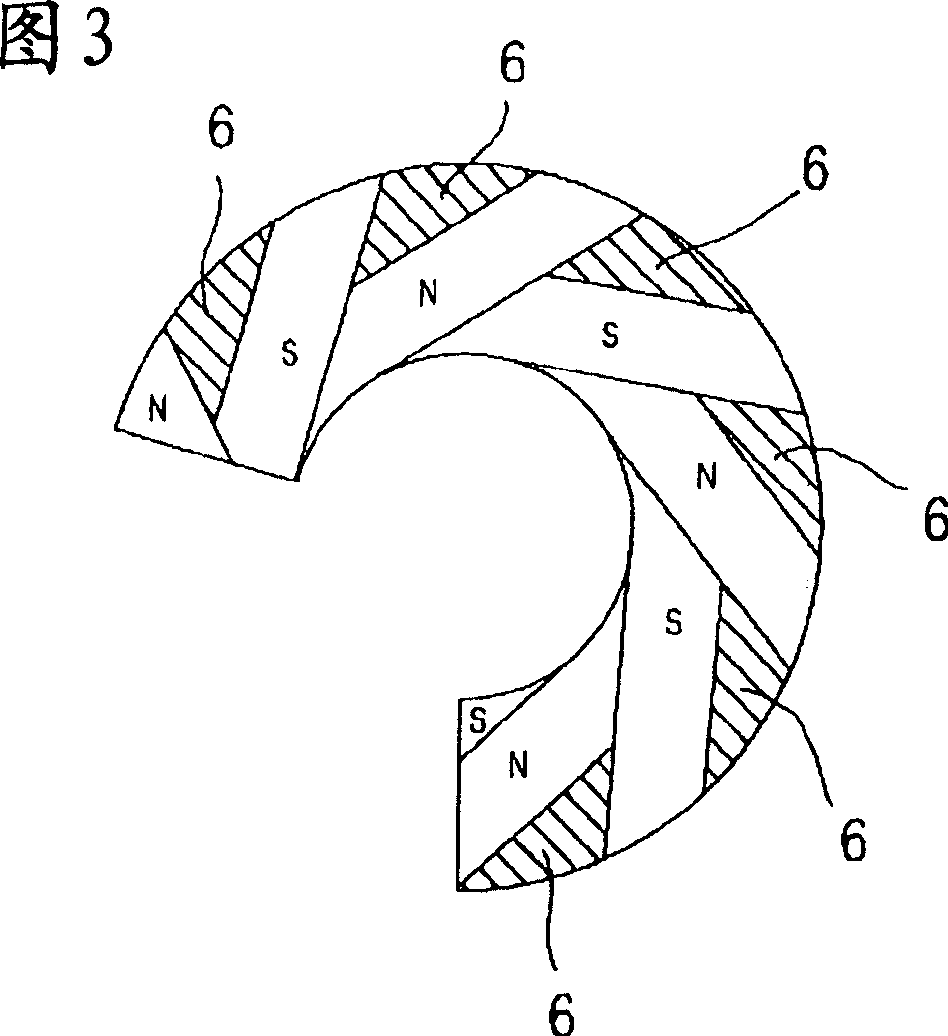

[0042] The drive magnet wheel 3 that is fixed on the drive shaft 1 is composed of a cylindrical magnet wheel 3a and frustoconical magnet wheels 3b, 3c arranged on both axial sides of the magnet wheel. The frustoconical magnet wheel 3b and 3c make the truncated conical surface face each other, and are arrange|positioned sandwiching the cylindrical magnet wheel 3a.

[00...

Embodiment 2

[0052] Figure 4 and Figure 5 It is a driving device, which respectively forms the driving magnet wheel 8 fixed on the drive shaft 1 and the driven magnet wheel 9 fixed on the driven shaft 2 into a drum shape, and arranges the two magnetic wheels at right angles in a non-contact state. The concave surface of wheel 8,9.

[0053] The drum-shaped magnetic wheels 8, 9 are the same as the driven magnetic wheel 4 of the above-mentioned embodiment 1, and the cylindrical magnetic wheels 8a, 9a and the truncated conical surfaces arranged oppositely on both sides in the axial direction are formed. Shaped magnetic wheels 8b, 8c, 9b, 9c constitute.

[0054] That is, the driven magnet wheel 4 of the first embodiment described above has the same configuration as the drive magnet wheel 3 of the first embodiment described above, and is arranged to cross at right angles in a non-contact state. In addition, the cylindrical magnet wheels 8a, 9a constituting the drive magnet wheel 8 and the d...

Embodiment 3

[0058] Image 6 and Figure 7 It is a driving device, and the driving device respectively forms the driving magnetic wheel 10 fixed on the driving shaft 1 and the driven magnetic wheel 11 fixed on the driven shaft 2 into a drum shape, and the two magnetic wheels 10, 11 make their truncated conical surfaces A frusto-conical magnet wheel is arranged oppositely on the shaft, and the concave curved surfaces of the drive magnet wheel 10 and the driven magnet wheel 11 are arranged to intersect at right angles in a non-contact state.

[0059] That is, it is a configuration in which the cylindrical magnet wheels 8a, 9a are removed from the configuration of the driving magnet wheel 8 and the driven magnet wheel 9 of the second embodiment described above. In addition, frustoconical magnet wheels 10 a , 10 b , 11 a , 11 b constituting the driving magnet wheel 10 and the driven magnet wheel 11 are respectively formed to have the same diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com