Organic electroluminescent device

An electroluminescent layer and luminescent technology, applied in the direction of electroluminescent light source, electric light source, light source, etc., can solve problems such as structural limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be specifically described with reference to these drawings.

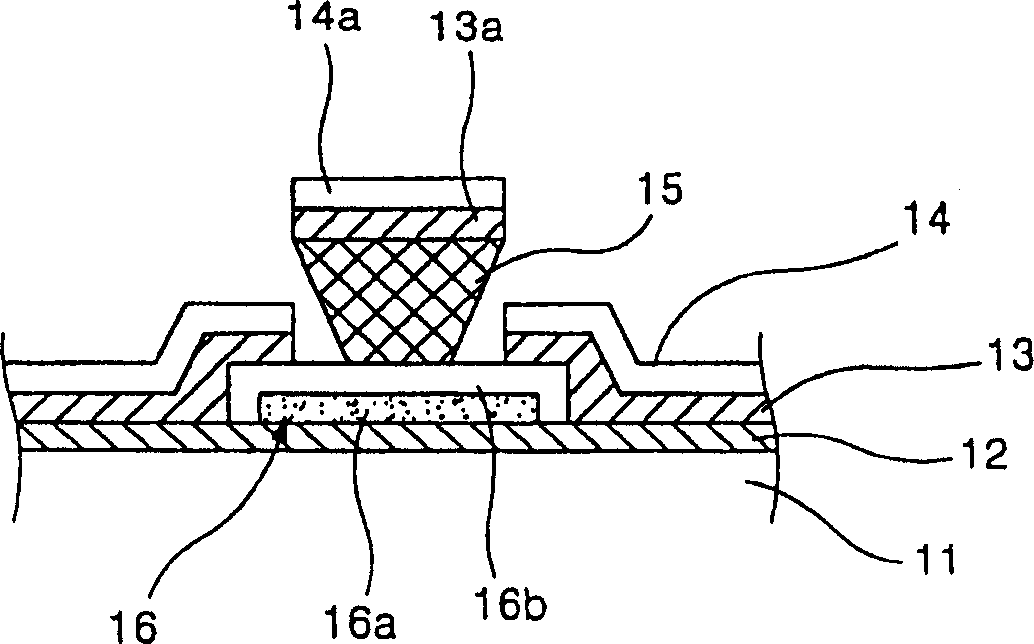

[0024] image 3 is a partial sectional view of the organic electroluminescent device according to the first embodiment of the present invention, which corresponds to figure 2 Part "B" of .

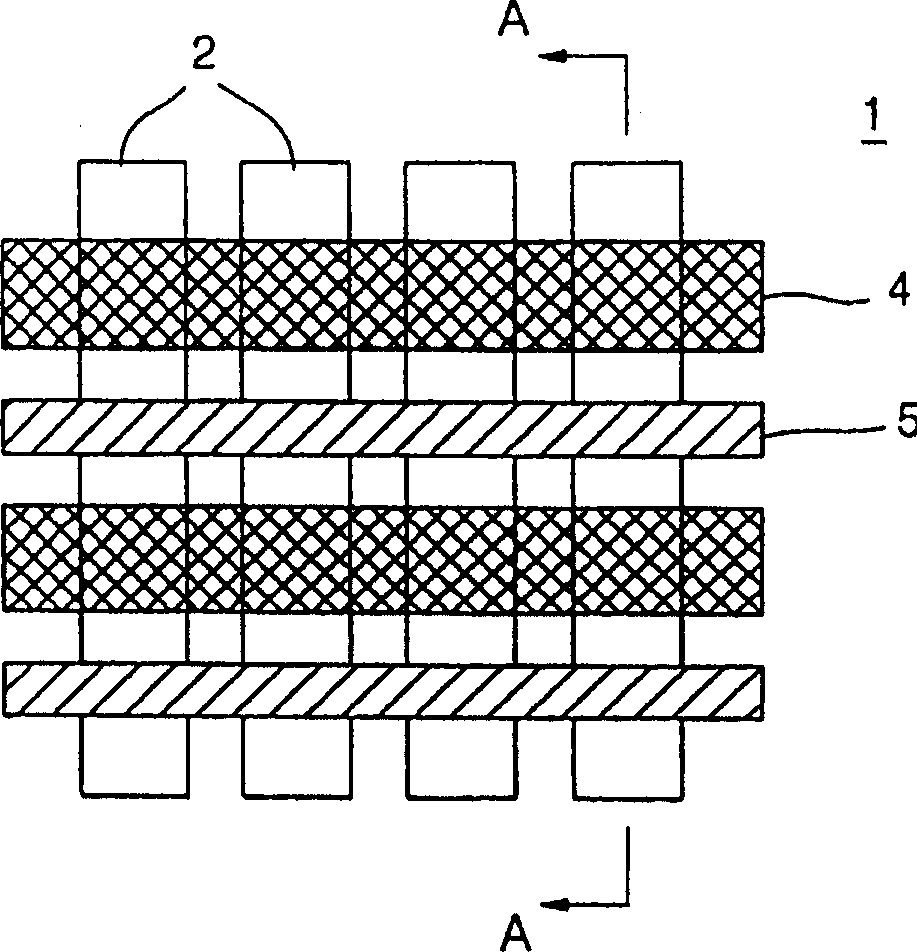

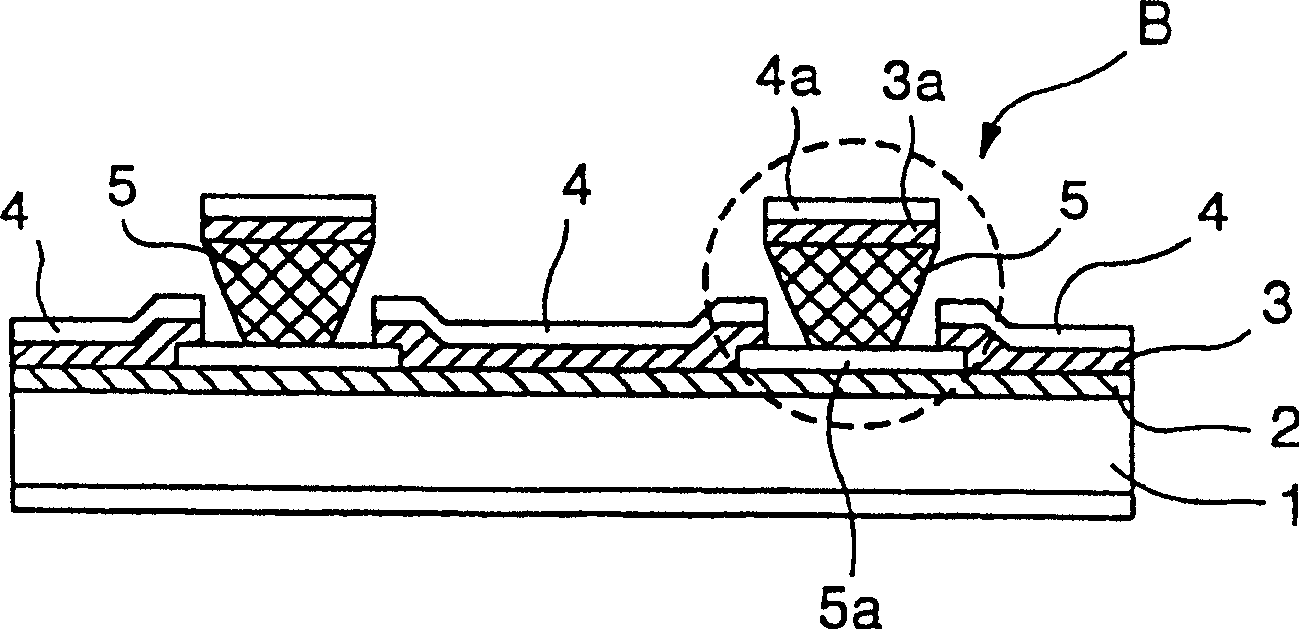

[0025] The whole structure of the organic electroluminescence device in this example is the same as figure 1 and figure 2 as shown. Therefore, only the characteristic part of the organic electroluminescent device in this embodiment is enlarged and shown in image 3 middle.

[0026] Refer below image 3 The procedure for manufacturing the organic electroluminescence device and its structure are described.

[0027] First, an ITO layer 12 is formed on a glass substrate 11 by a vacuum deposition method, and the ITO layer 12 is patterned by a photolithography method to form an ITO electrode. Then, an insulating layer 16 is formed in certain regions of the ITO lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com