Automatic vertical-flow oil-separating precipitator

An oil-separating sedimentation and automatic technology, which is applied in the direction of grease/oily substance/floating matter removal device, liquid separation, separation method, etc., can solve problems such as unstable operation, low oil removal rate, and substandard water output, and achieve operational efficiency Stability, good oil separation effect, less maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific structure, working process and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

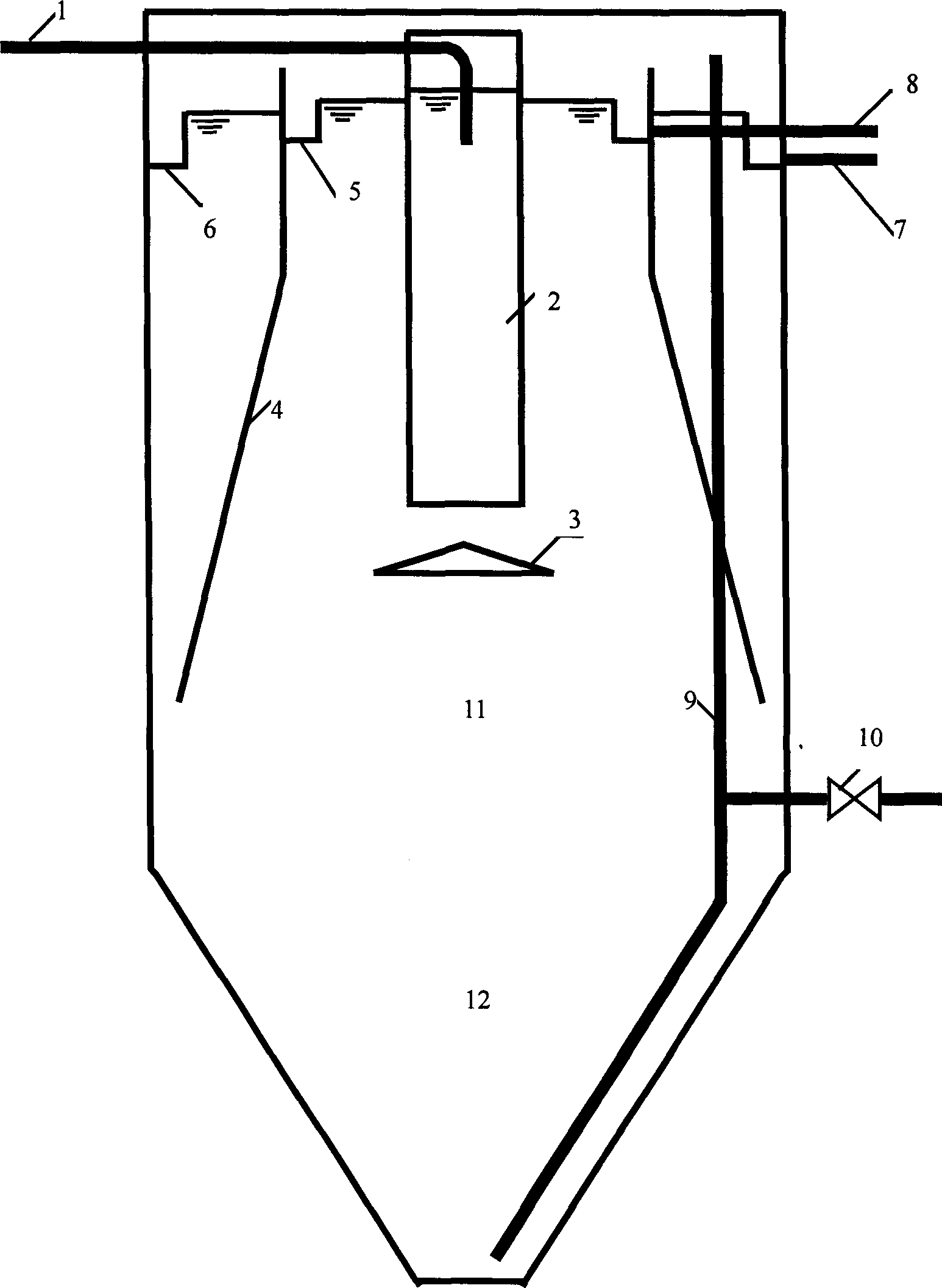

[0014] The structure of the vertical flow automatic oil separation and sedimentation device provided by the invention is as follows: figure 1 As shown, the device mainly includes a pool body composed of a separation zone 11 and a mud bucket 12, a water inlet pipe 1, a central guide tube 2 arranged on the upper part of the separation zone 11, a conical reflector 3 at the bottom of the central guide tube, and an outlet pipe 1. Water pipe 7, oil outlet pipe 8, mud discharge pipe 9, deflector 4, oil outlet weir 5 and water outlet weir 6. The deflector 4 is set in the separation area 11 and arranged concentrically with the central deflector cylinder. The upper part of the deflector has the same shape as the separation area 11, and its lower part is bell-shaped; the oil outlet weir 5 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com