Drum type washing and drying machine

A washing-drying machine, drum-type technology, which is applied to household dryers, washing machines with containers, washing devices, etc., can solve the problems of reduced blasting capacity, reduced drying performance, troublesome operation, etc., and achieves improved convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

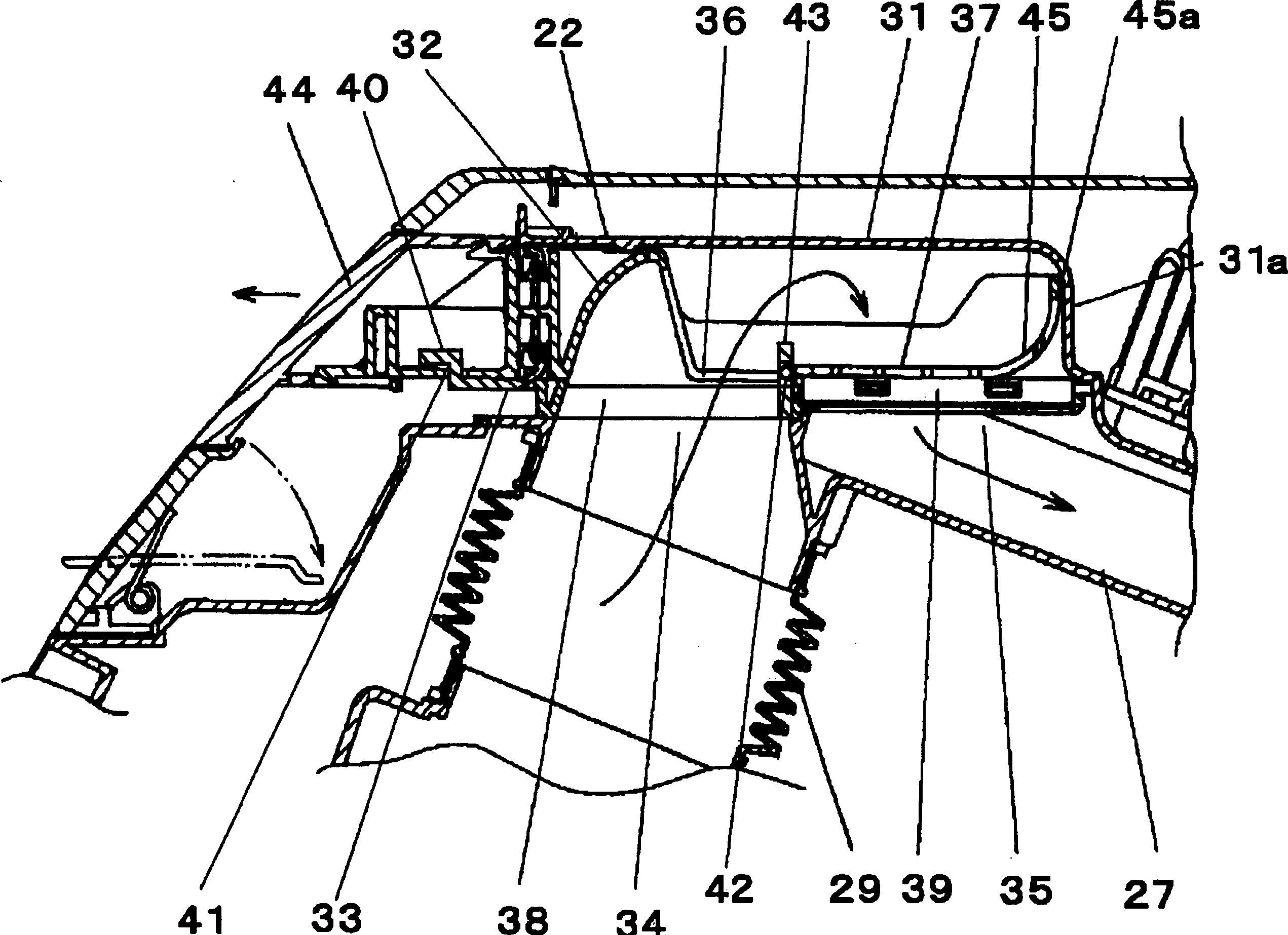

[0017] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that such examples do not limit the present invention.

[0018] The following pass Figure 1-6 Now, the drum-type washer-dryer described in the embodiments of the present invention will be described in detail.

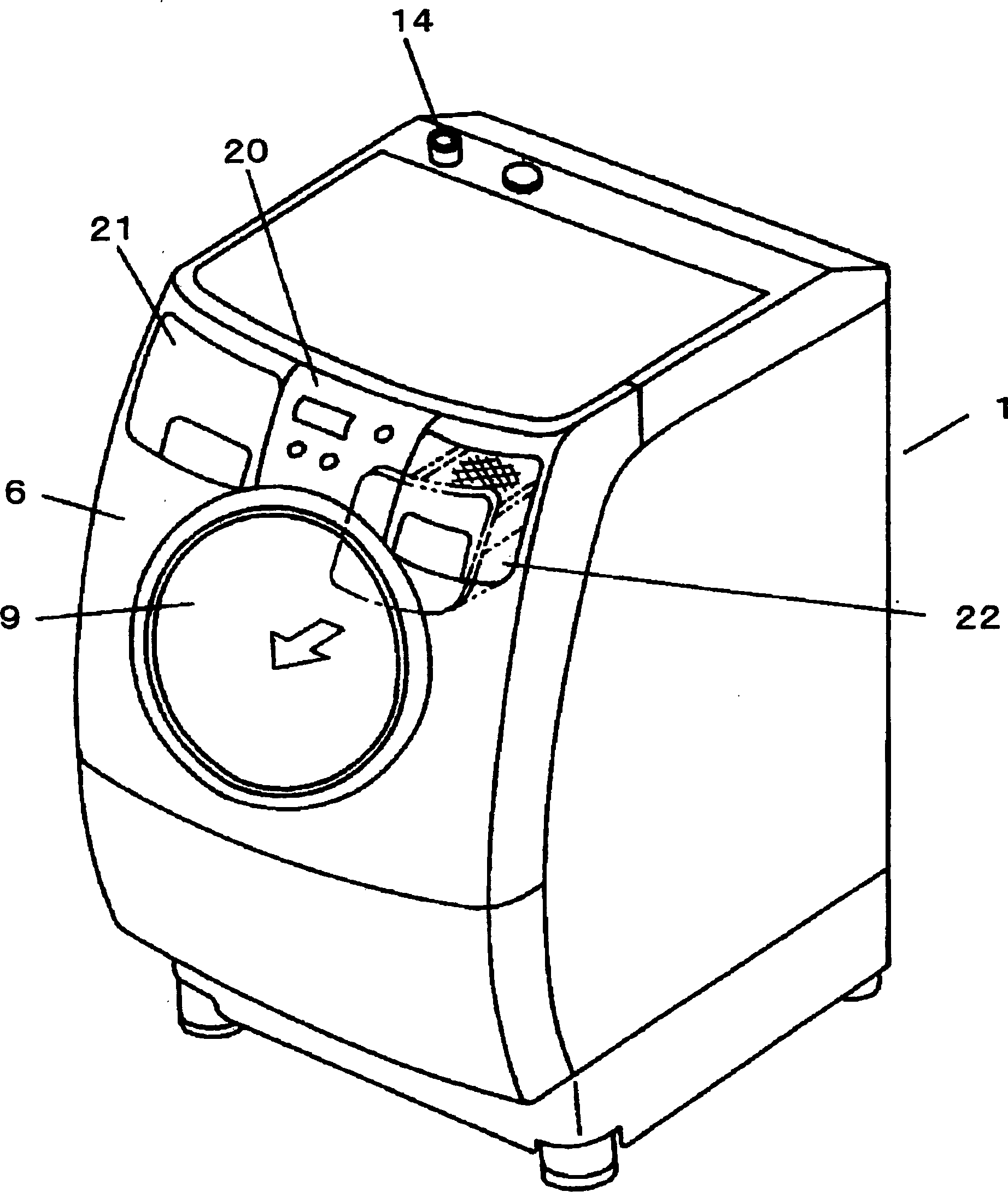

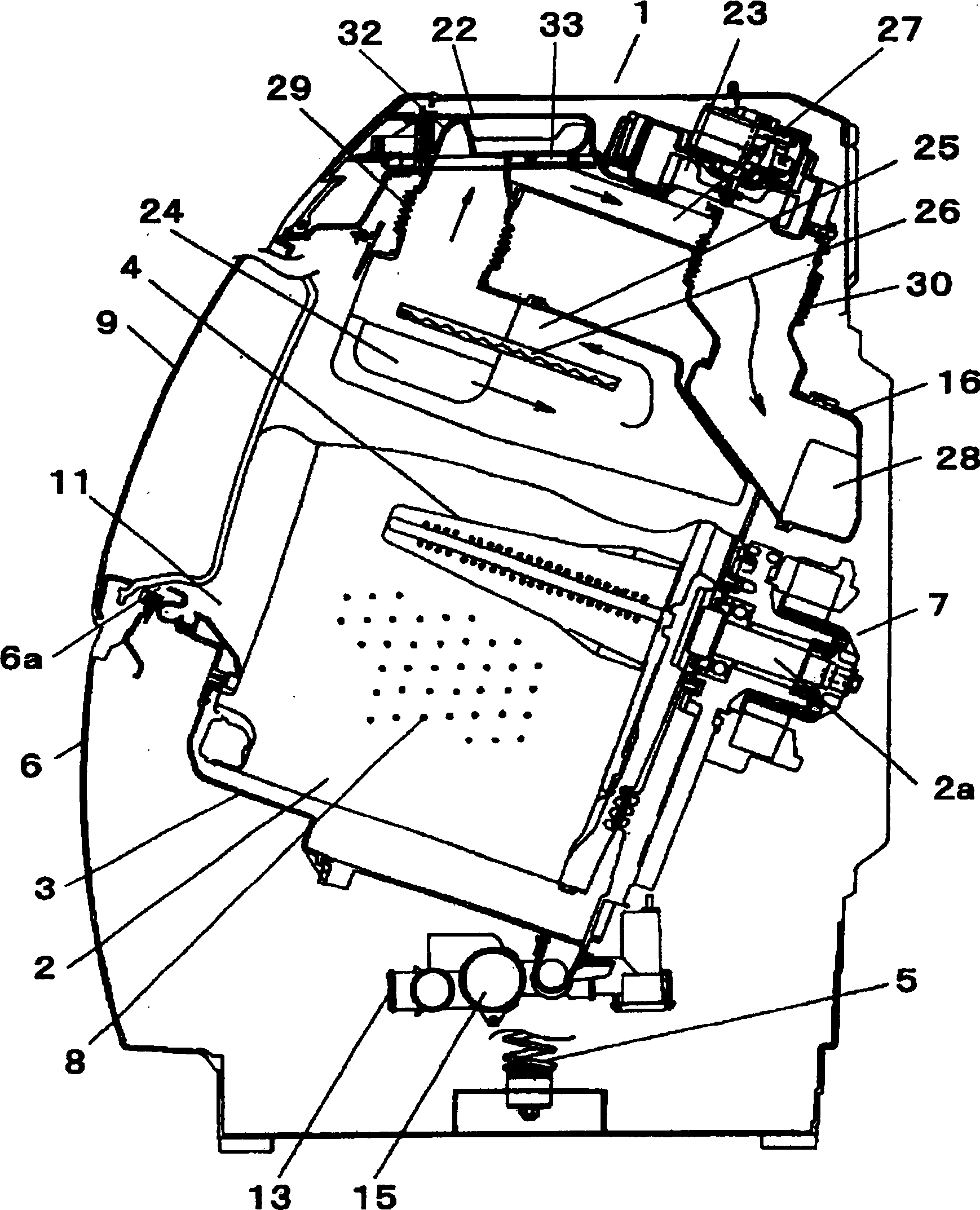

[0019] Such as figure 1 and figure 2 As mentioned above, in the body 1 of the drum type washer-dryer of the present invention, the tub 3 is set in a suspended state through the damping structure 5 and other components. Inside the tub 3 is a bottomed cylindrical rotating drum 2 that is rotatable, and the axis direction of the rotating shaft 2a in the rotating drum 2 is set to be inclined downward from the front side to the back side. On the front side of the tub 3 , there is a clothes inlet and outlet 11 communicating with the opening of the rotary drum 2 . On the front portion of the front frame 6 constituting the front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com