Rolling piston capable of changing sliding friction to rolling friction between piston and cylinder

A rolling piston and sliding friction technology, applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of troublesome replacement of piston rings and cylinder liners, easy wear, and reduced efficiency, so as to reduce mechanical wear, prolong service life, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention.

[0017] A method for changing sliding friction between a piston and a cylinder into rolling friction is realized by rolling marbles or rollers on the cylinder wall.

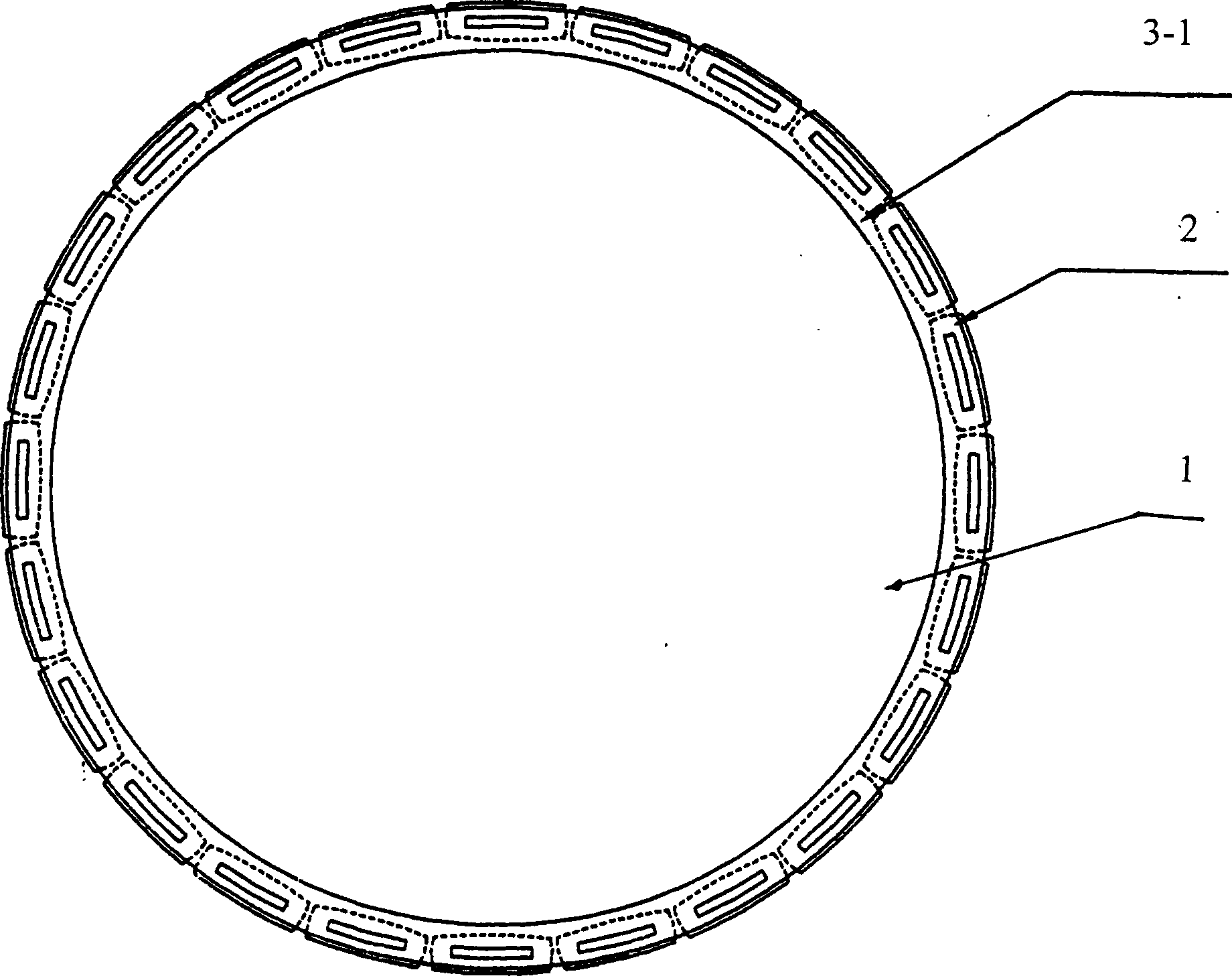

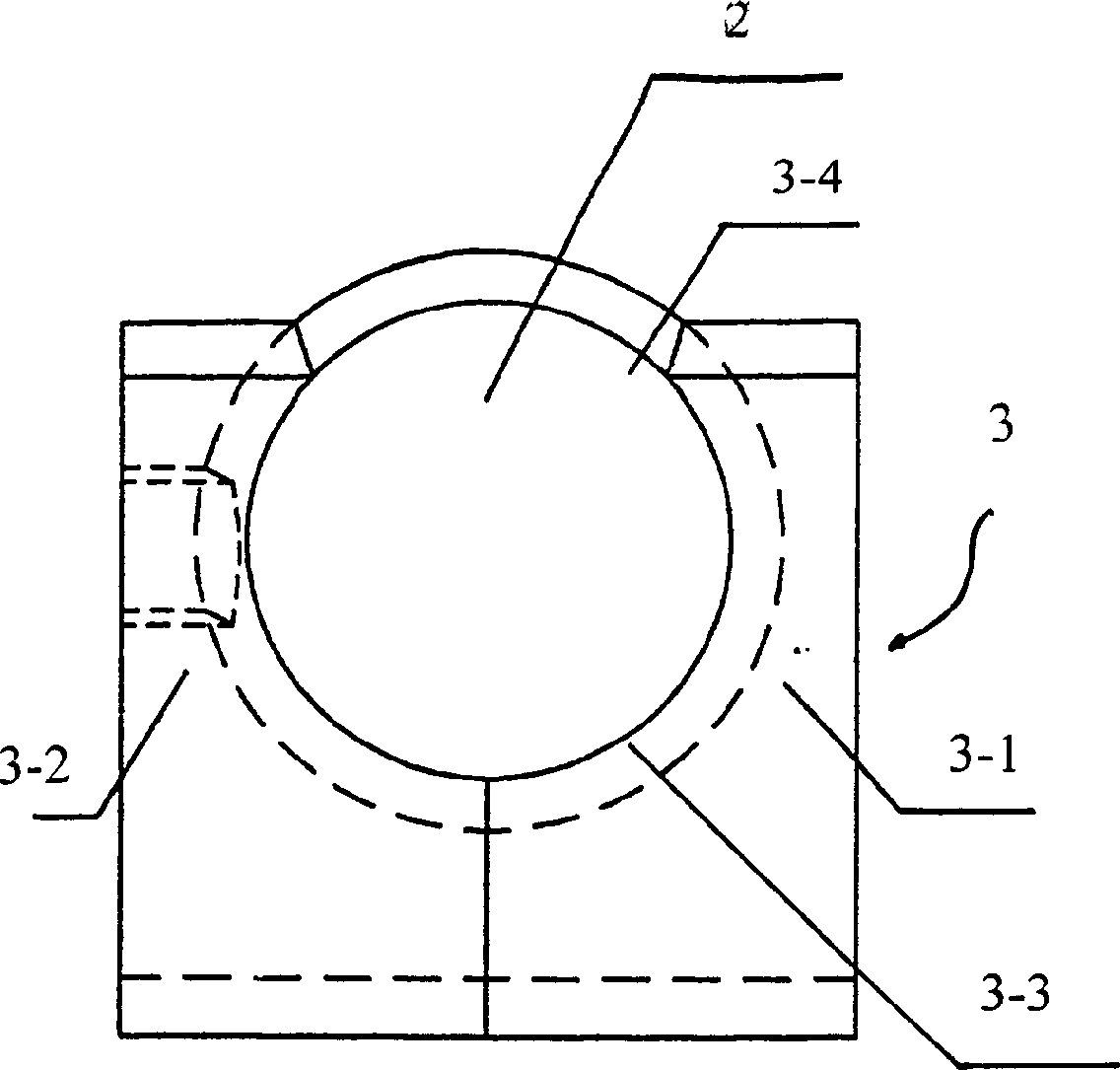

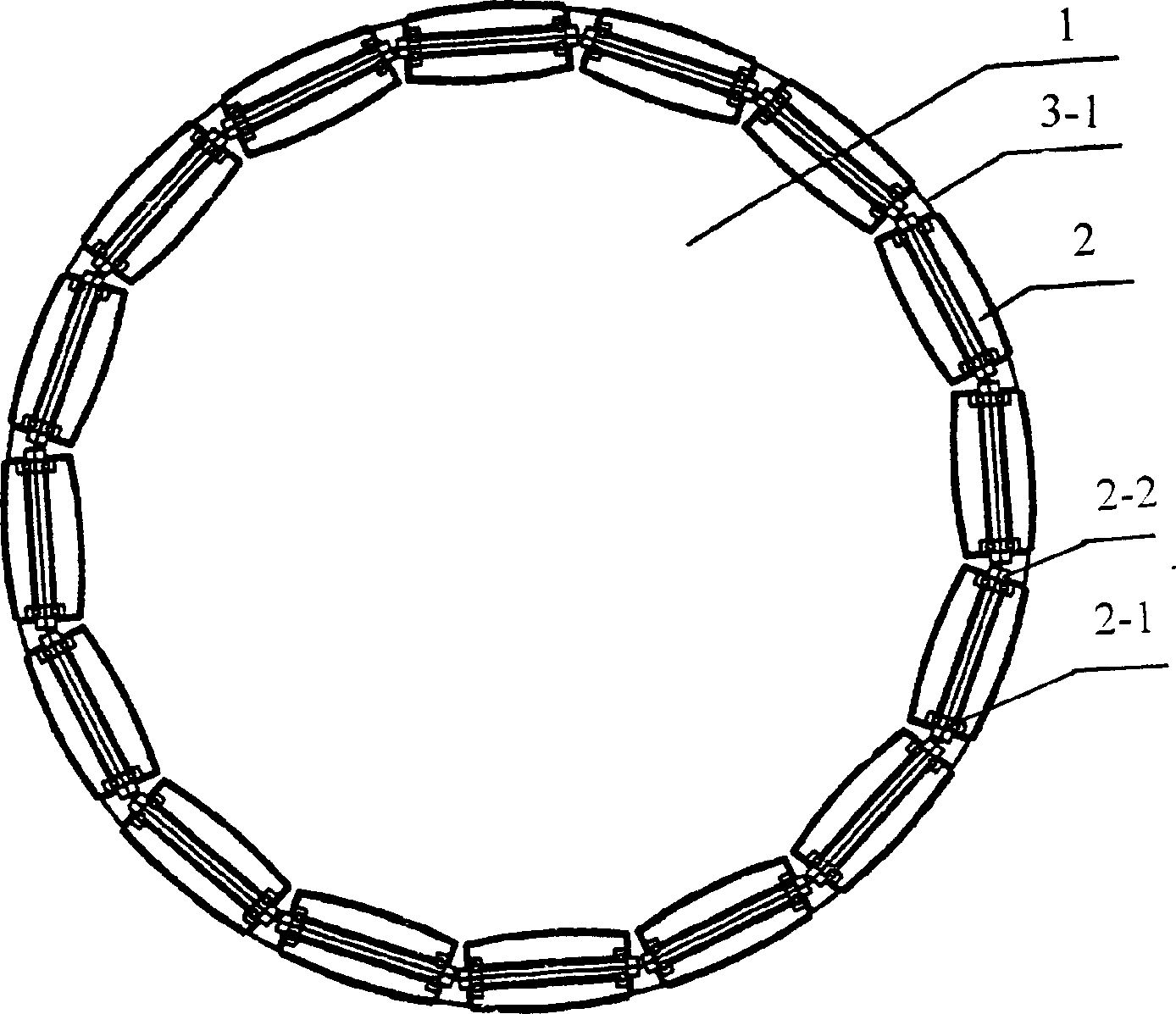

[0018] refer to figure 1 , figure 2 It can be seen that one embodiment of the present invention is composed of a piston body 1 and several rolling elements 2 located around the piston body, and there is a connecting fixture 3 between the piston body and the rolling elements.

[0019] The rolling body 2 is a roller, the connecting fixture includes an upper piston sleeve 3-1 and a lower piston sleeve 3-2, and the roller 2 is located between the upper piston sleeve 3-1 and the lower piston sleeve 3-2 In the groove 3-3, and partially located outside the opening 3-4 between the upper piston sleeve and the lower piston s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com