Testing box for measuring anti-pulling force of soil nailing mechanical property

A test box, pull-out force technology, applied in the direction of using stable tension/pressure test material strength, measuring device, using mechanical device, etc., can solve the problem of increasing water saturation, unable to measure soil nail stress, not having, etc. problem, to achieve the effect of increasing water saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

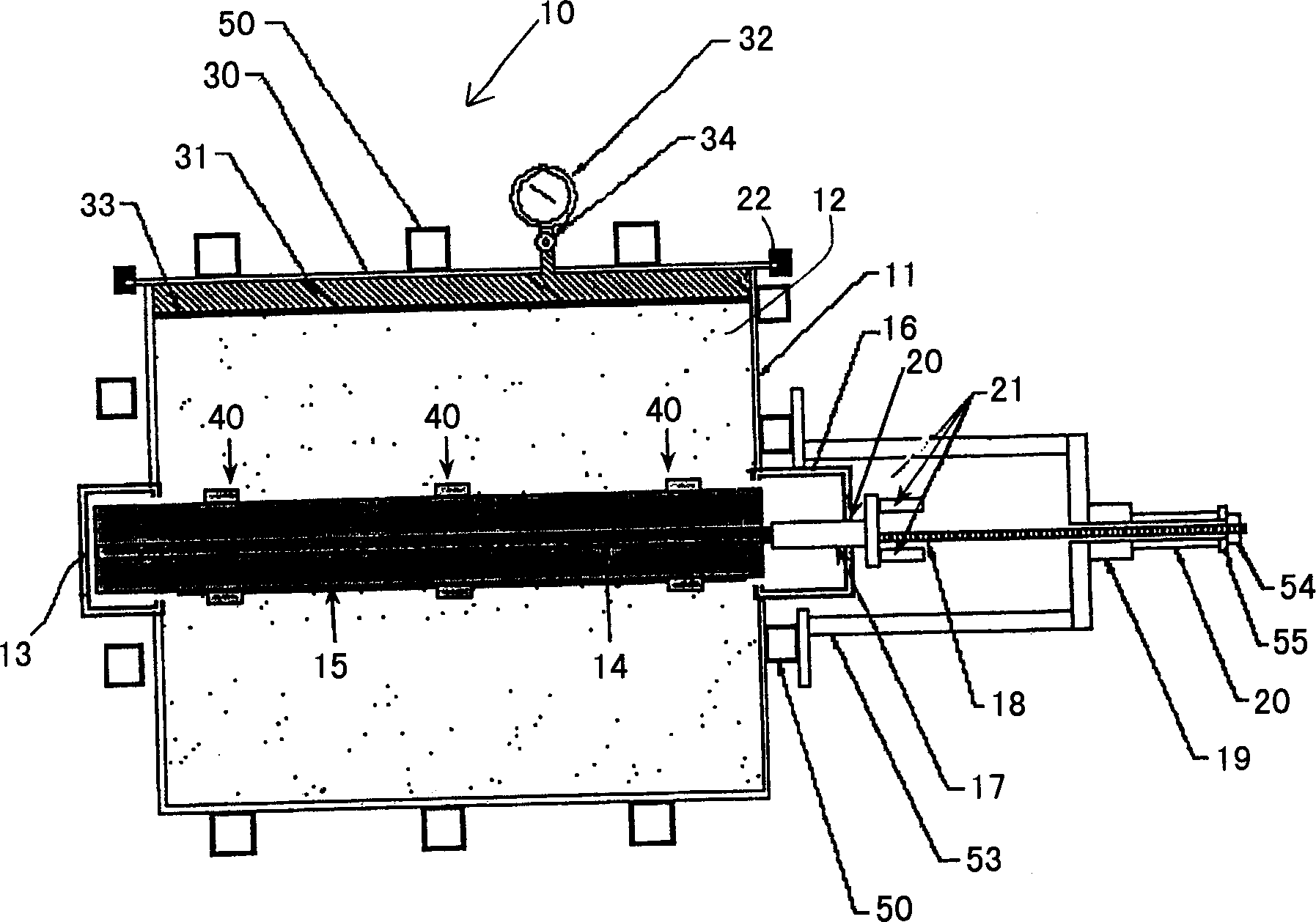

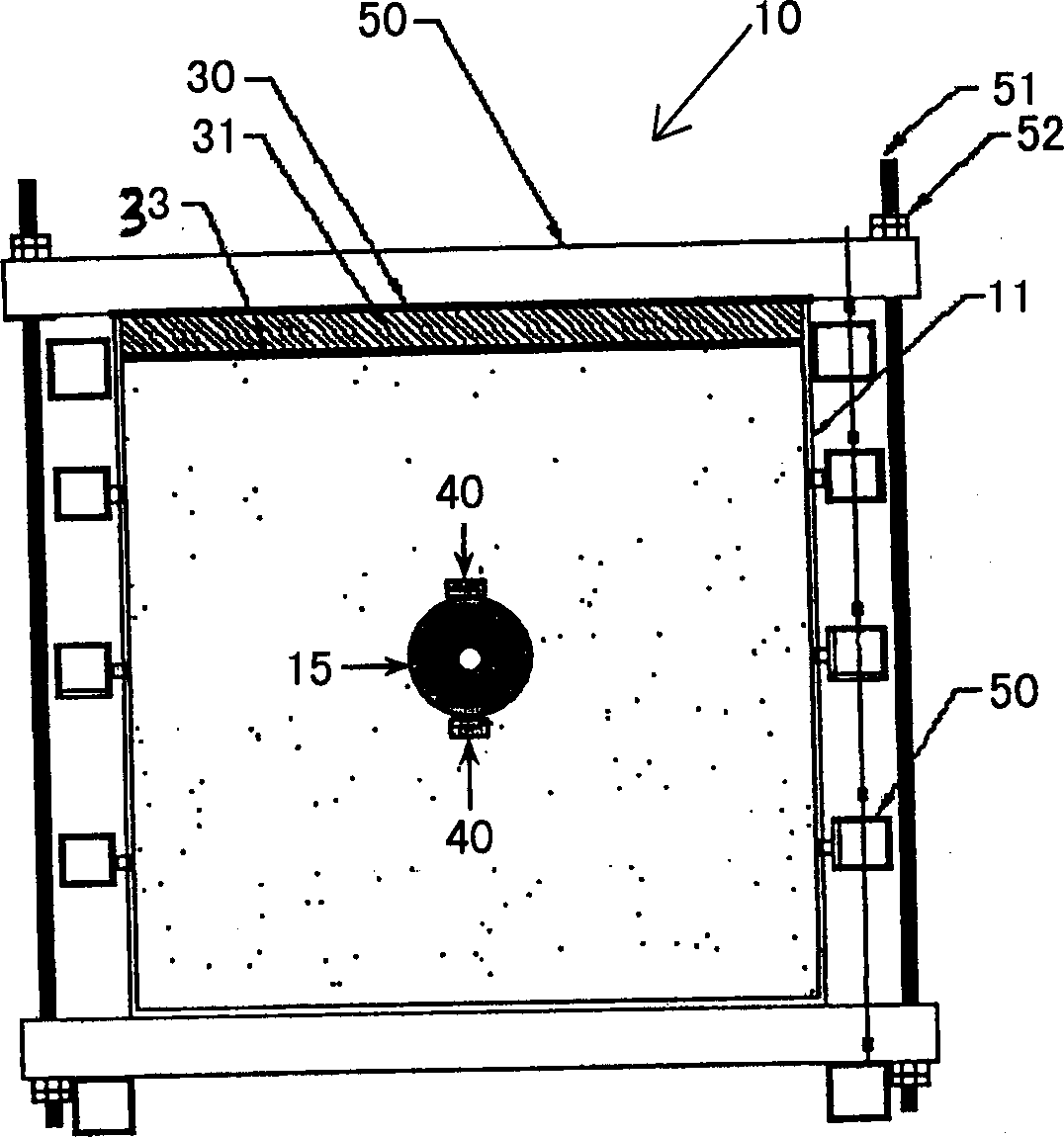

[0024] like figure 1 and figure 2 Said, the pullout resistance test box 10 of the present invention comprises a test box main body 11, and this test box main body 11 is in the shape of a hollow cuboid, and its inside is filled with rock and soil samples 12, and this rock and soil samples can be completely decomposed flowers, for example. Granite rock and soil, that is, CDG rock and soil. The upper end of the main body 11 of the test box is open, and the opening is closed by a cover plate 30 . Below the cover plate 30 , a rubber water bag 31 is arranged on the surface of the rock-soil sample 12 , and the rubber water bag 31 exerts vertical pressure on the rock-soil sample 12 . First fill the rock soil sample 12 with carbon dioxide gas, fill the rock soil sample 12 with deaerated water, and then apply backwater pressure to the rock soil sample 12 in the box 11 through the rubber water bag 31 . Taking these measures will increase the water saturation of the soil sample 12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com