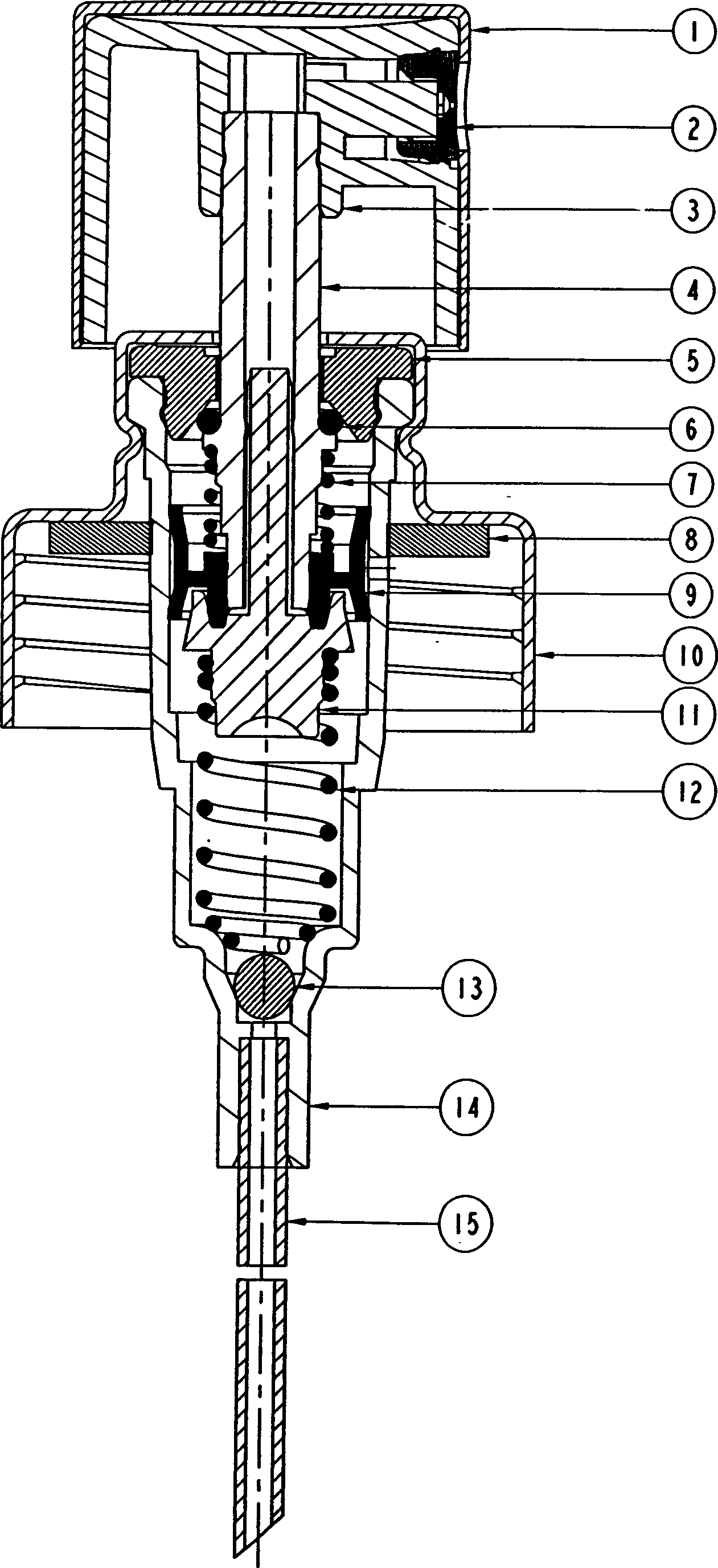

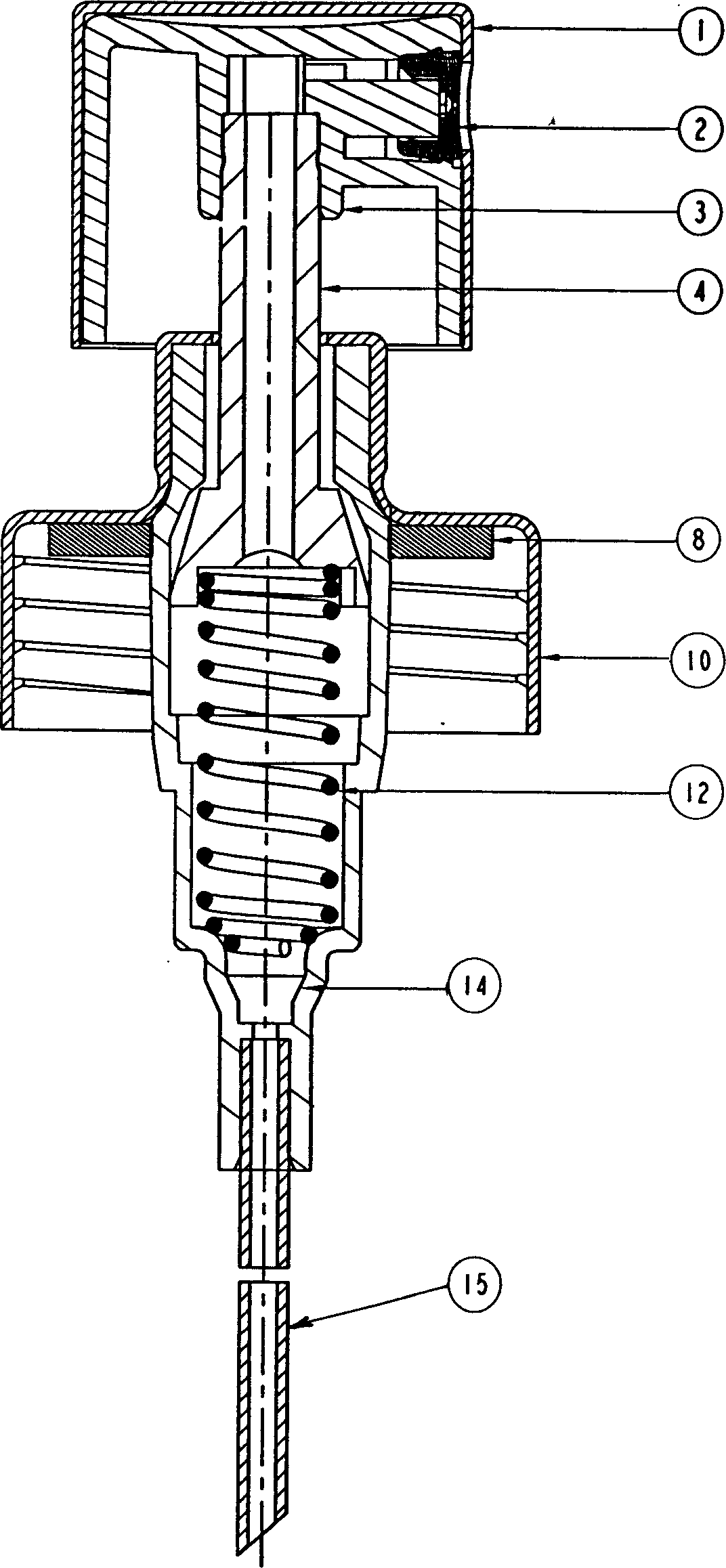

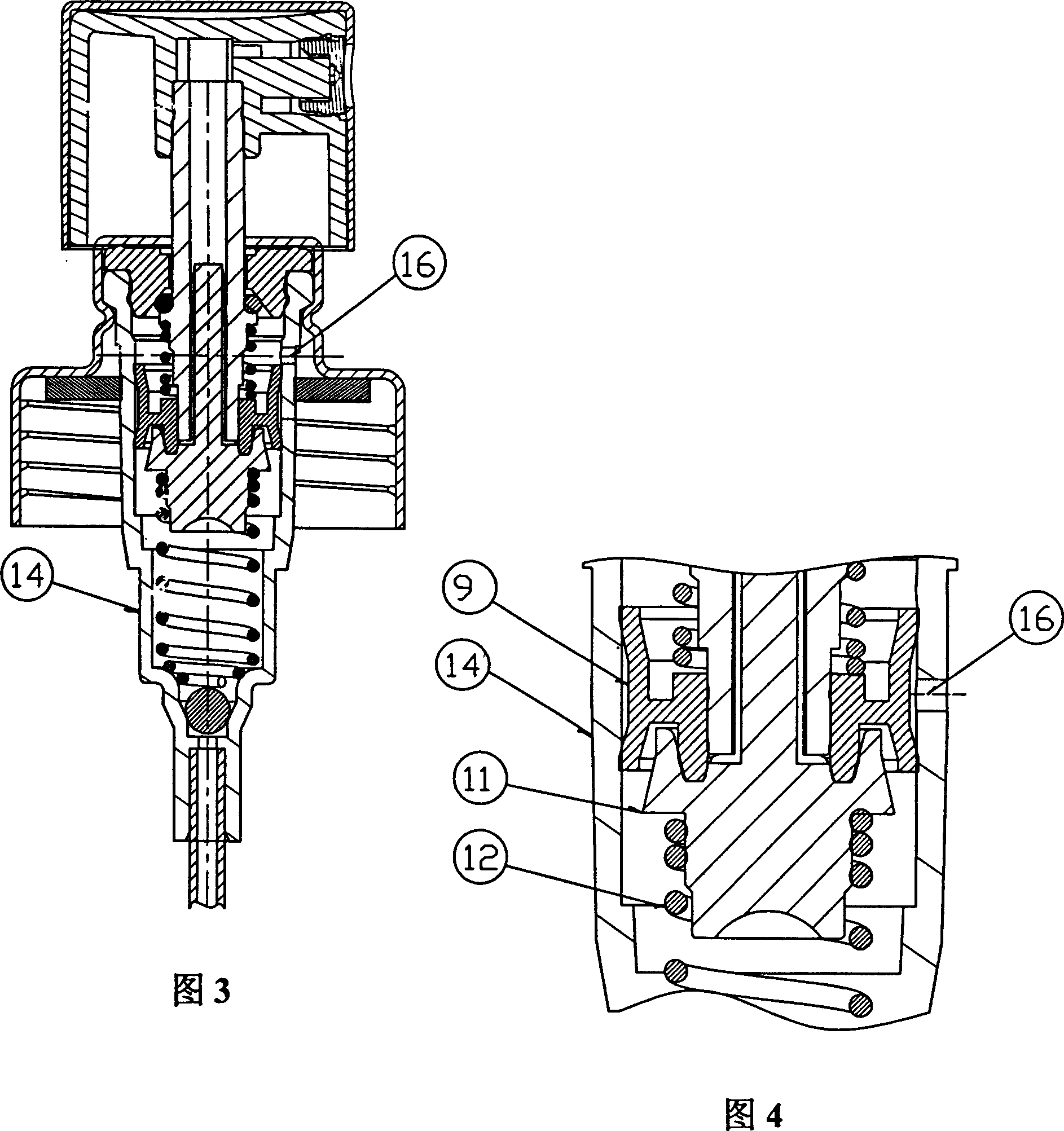

Miniature sprayer sealing device

A sealing device and sprayer technology, applied in the directions of spraying device, liquid spraying device, liquid distribution, etc., can solve the problems of non-sealing, user inconvenience, liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation mode takes the working principle of the present invention as an example. When put into practice, the pump body 14 is placed in the liquid bottle (the drawing of the liquid bottle is omitted in the accompanying drawings), and the thread of the bayonet 10 is screwed tightly with the screw of the bottle neck. When the lower pressure head presses the cap 1, the valve stem 4 drives the whole system to move downward. At this time, the internal pressure of the pump body 14 increases continuously. When the pressure is greater than the pressure of the short spring 7 on the piston 9, the seal between the piston 9 and the valve needle 11 Disconnected at B. The short spring 7 is sleeved on the valve stem 4, with one end against the step surface of the valve stem 4 and one end against the end face of the piston 9. The pressure increases the sealing of the joint between the piston 9 and the valve needle 11. The liquid at h inside the pump body 14 flows into the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com