Compressor and exhaust residue heat mixed driven Automobile air conditioning-refrigerating system

A technology of automotive air conditioning and hybrid drive, which is applied in the direction of refrigerators, refrigeration and liquefaction, and machine operation methods. It can solve the problems of expensive metal hydrides, complicated devices, and unrealistic problems, and achieve significant social and economic benefits. Increased components and costs, and significant energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

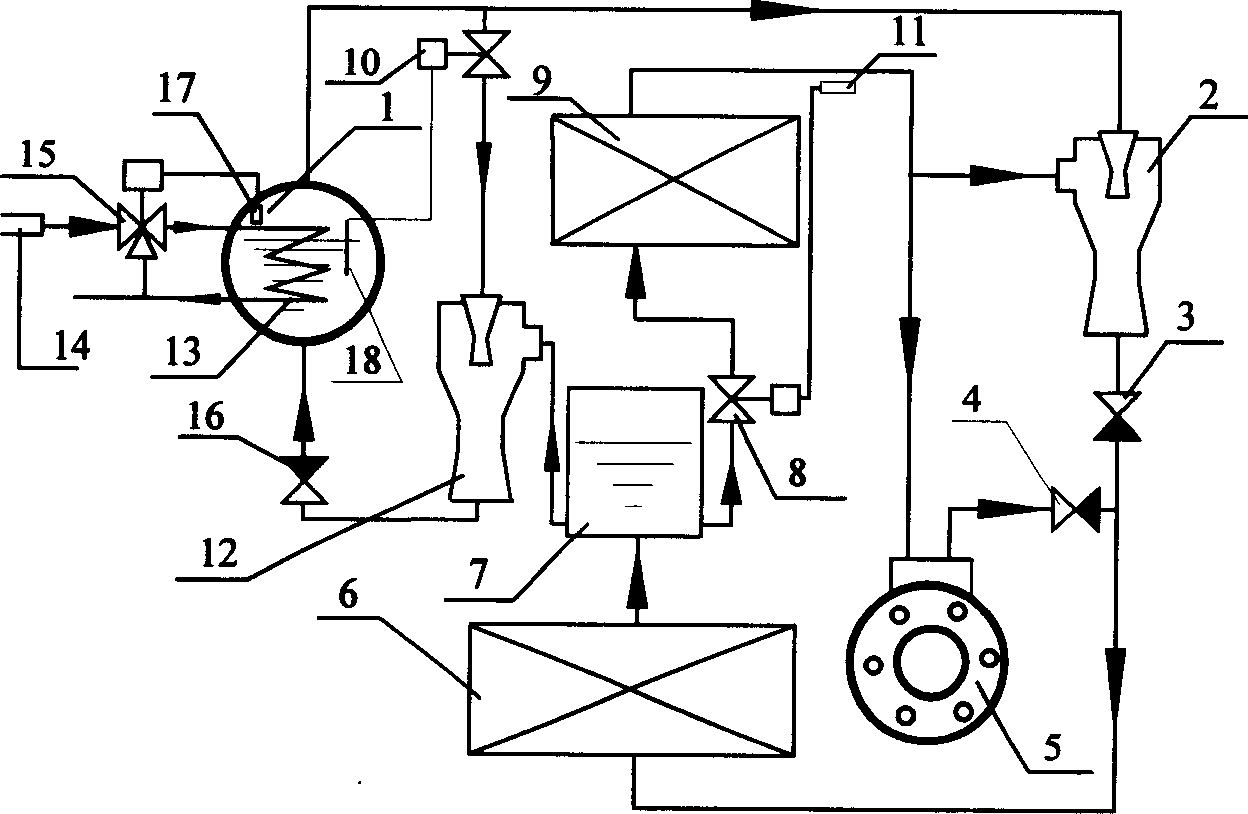

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention includes: generator 1, steam ejector 2, A check valve 3, B check valve 4, compressor 5, condenser 6, liquid receiver 7, expansion valve 8, evaporator 9, Solenoid valve 10, expansion valve temperature sensing package 11, vapor-liquid injector 12, heat exchange tube 13, three-way regulating valve 15, C check valve 16, temperature sensor 17, liquid level sensor 18. The compressor 5 adopts a variable-displacement automotive air-conditioning compressor, which can adjust the cooling capacity for different vehicle speeds. The three-way regulating valve 15 is located on the exhaust gas outlet pipe, and the heat exchange tube 13 is placed in the generator 1 for heating the exhaust gas in the generator 1. The refrigerant. The outlet of the automobile exhaust pipe 14 is connected with the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com