Main engine axis positioning method and measuring device

A technology for positioning measurement and positioning tooling, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the measurement of coaxiality cannot be completed, and achieve the effect of improving the quality of the whole machine and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

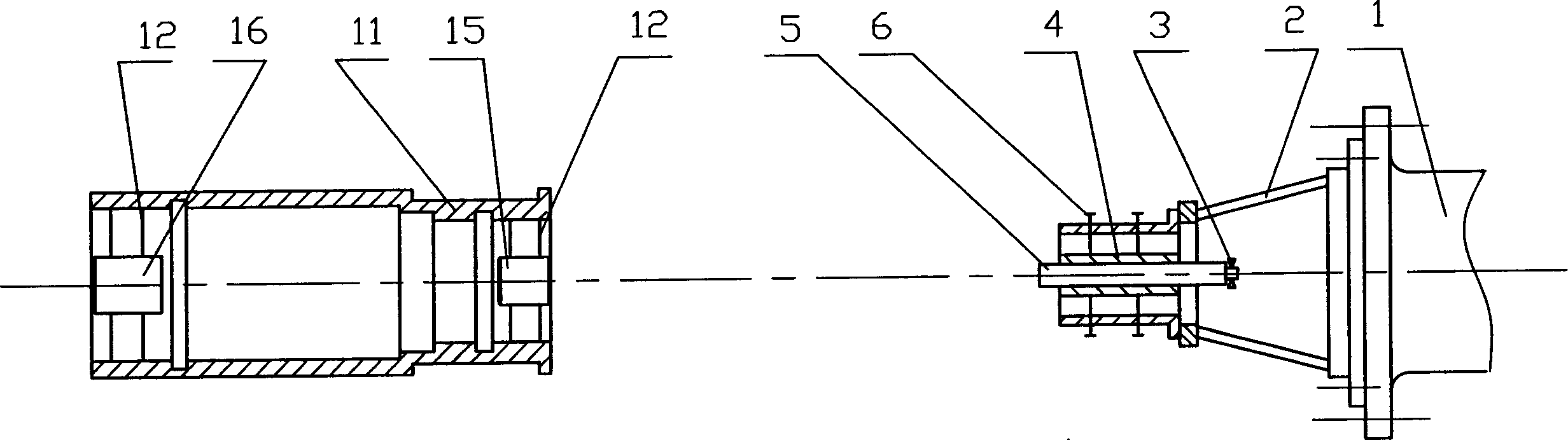

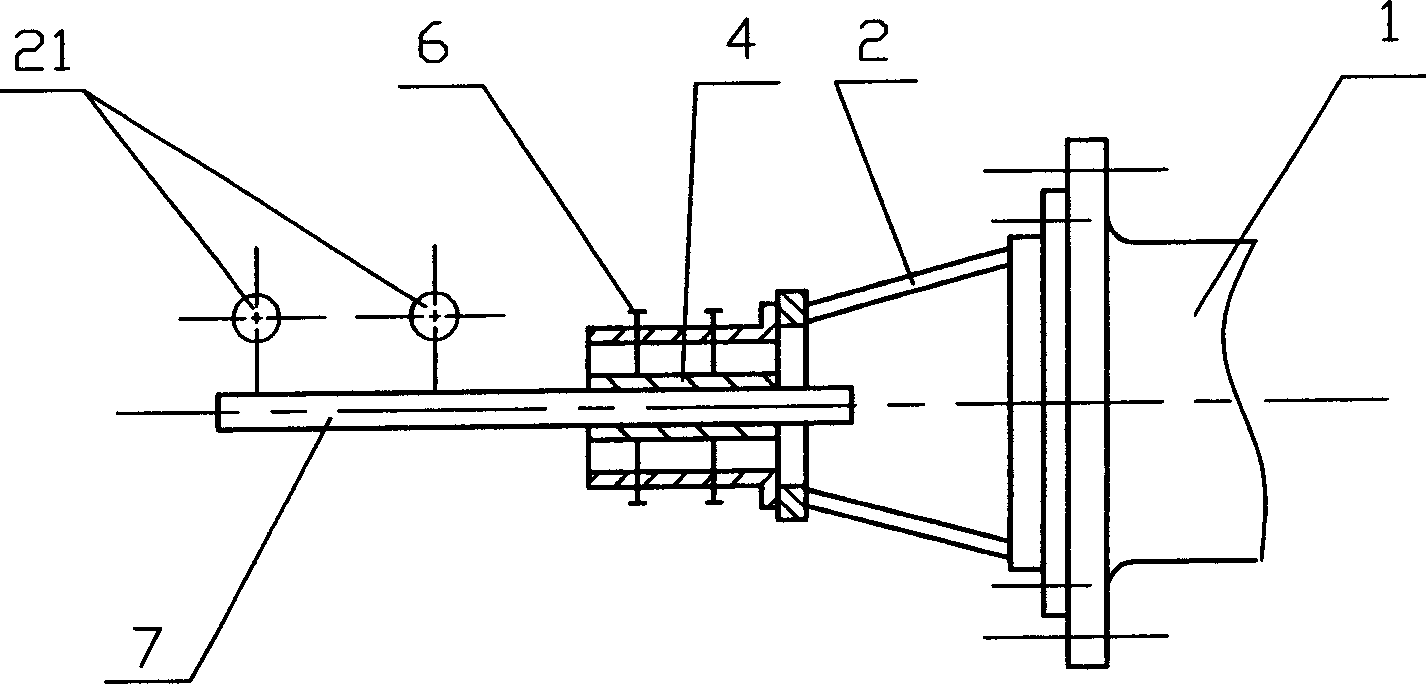

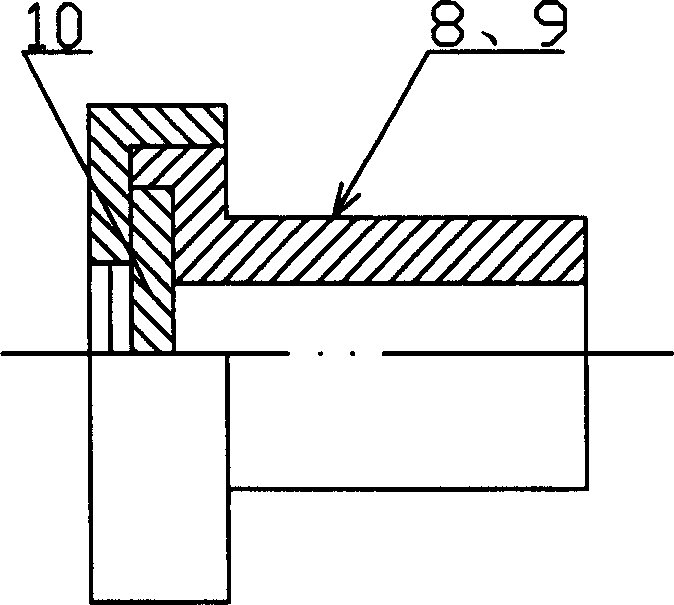

[0022] The axis positioning method and measuring device of the main machine are to realize the axis positioning of the main machine by adopting the micrometer collimation telescope and its accessories and the measuring device arranged along the optical path set therewith. The described micro-collimation telescope accessory includes Φ57.14mm, height 20mm, optical target sheet 10 and right-angle eyepiece 3 of precision 2 ". The host axis positioning measurement device includes two light targets for making and placing the optical target sheet 10. , 9, two light pipes 15 and 16 for setting up light targets 8 and 9, four light target supports 12 for setting up light pipes, the special-purpose internal micrometer positioning shaft 17 that cooperates with light pipes 15 and 16, and the main engine axis positioning tooling 2, Sleeve 4 and the false axis 7 matched with it. Utilize the micrometer collimation telescope, calibrate the light targets 8 and 9 with the optical target sheet 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com