Liquid-cooled column-type heat tube radiator

A heat pipe radiator, cylindrical technology, applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc. Large and other problems, to achieve the effect of compact structure, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

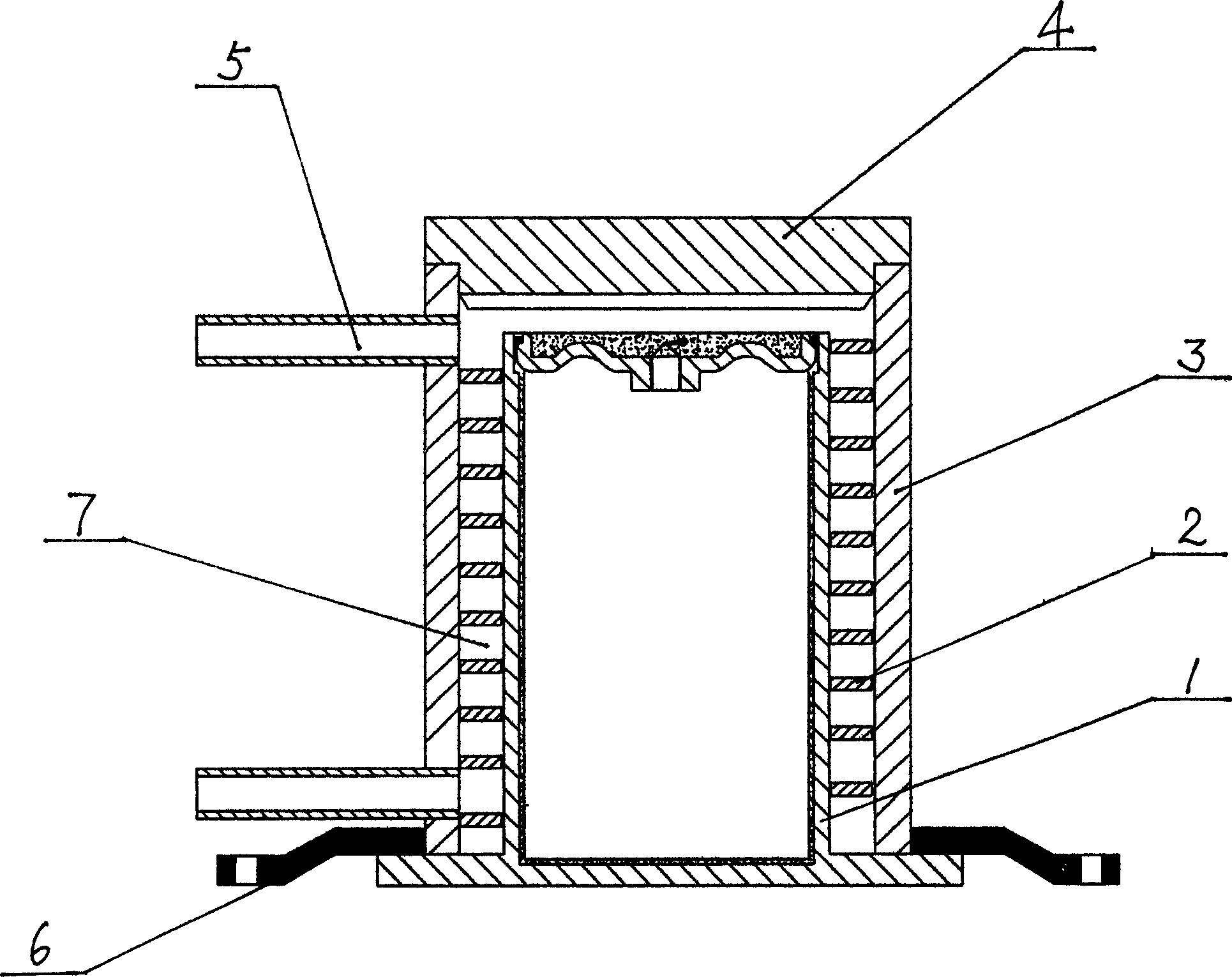

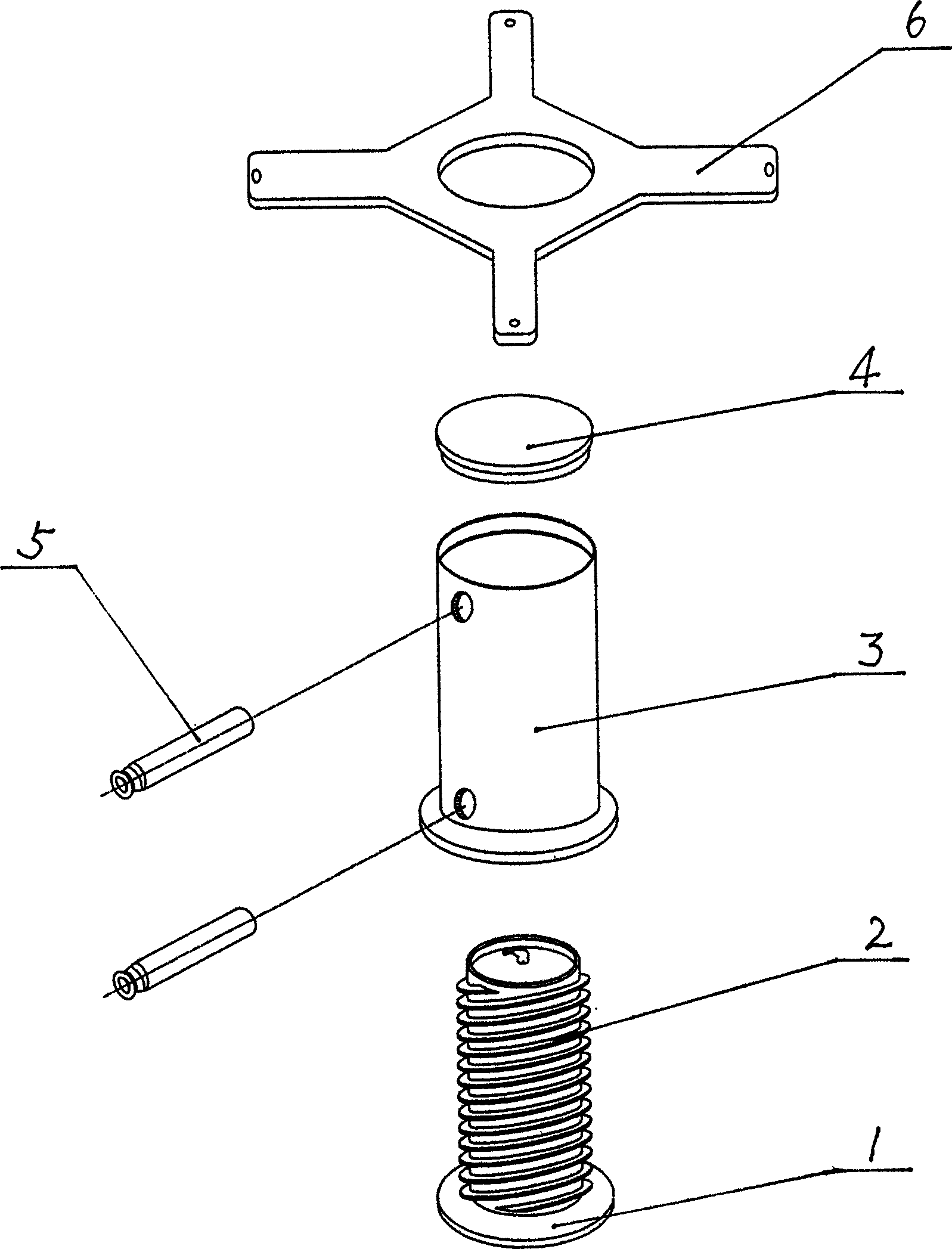

[0031] Embodiment 1: refer to figure 1 , figure 2 , this liquid-cooled cylindrical heat pipe radiator includes a cylindrical heat pipe 1, a deflector 2, an outer sleeve 3, a sleeve cover 4, a connecting pipe 5, and a buckle 6. A deflector 2 is socketed or welded on the outer wall of the tube body 1-2 of the cylindrical heat pipe 1. The deflector 2 is used to increase the flow rate and disturbance of the liquid and enhance heat transfer. At the same time, the deflector 2 and the cylindrical heat pipe The tube body 1-2 of 1 is in close contact to form a heat dissipation surface; an outer sleeve 3 is provided outside the deflector 2, and the inner wall surface of the outer sleeve 3, the outer wall surface of the cylindrical heat pipe 1 and the deflector 2 form a connected liquid channel 7; The upper end of the outer casing 2 is provided with a sleeve cover 4, and the outer casing 3 is provided with a liquid connecting pipe 5 respectively connected to both ends of the liquid pas...

Embodiment 2

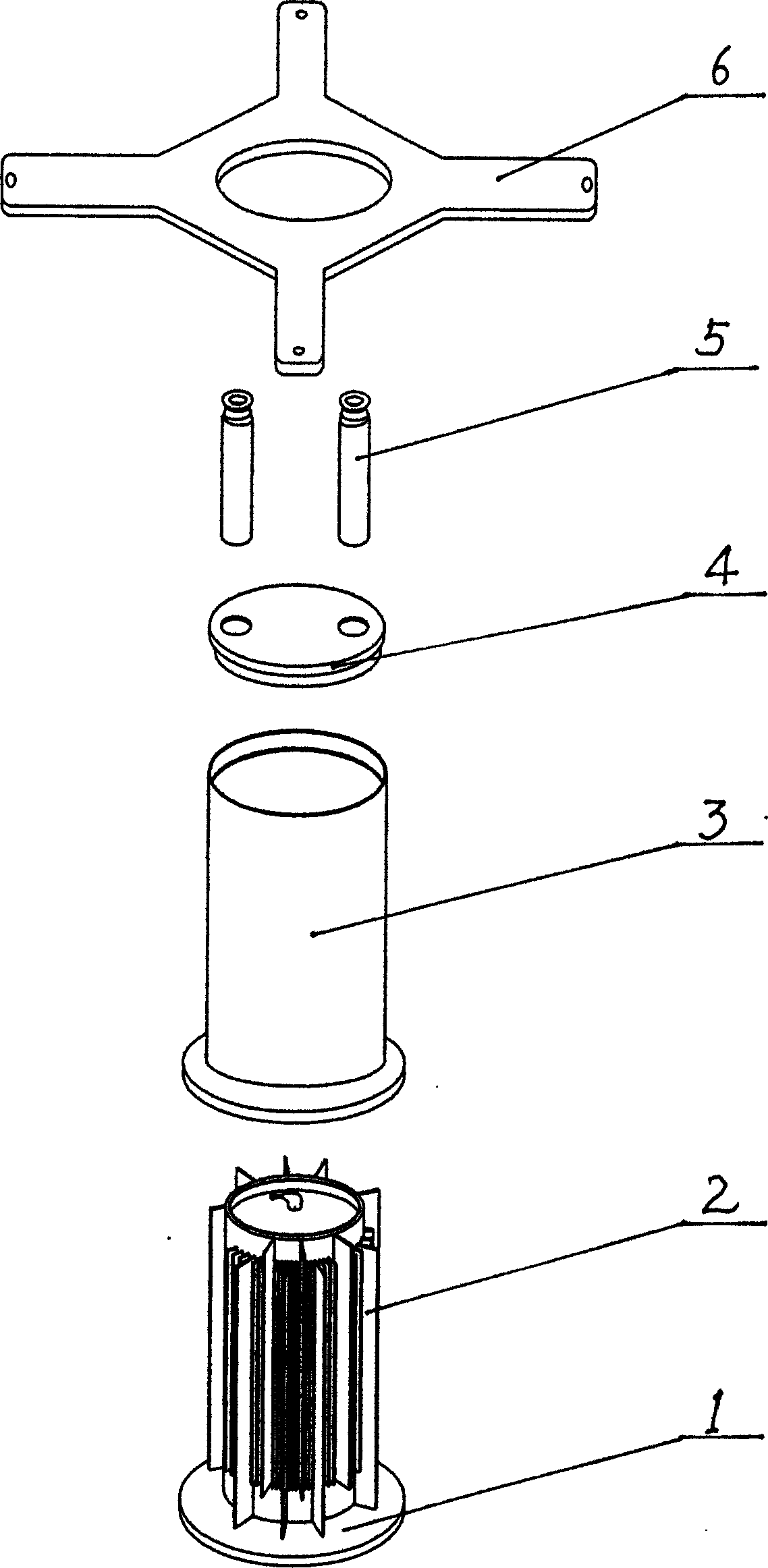

[0035] Embodiment 2: refer to image 3 , the difference from Embodiment 1 is that the liquid connecting pipe 5 is arranged on the sleeve cover 4 of the liquid-cooled cylindrical heat pipe radiator, and the buckle can be easily installed or replaced according to the use occasion and the fastening method. 6.

Embodiment 3

[0036]Embodiment 3: refer to Image 6 , the difference from Embodiments 1 and 2 is that one or more spiral deflectors 2 are welded or socketed on the outer wall of the cylindrical heat pipe 1 or directly on the outer wall of the cylindrical heat pipe 1 body 1-2, Cooperate with the inner wall surface of the outer sleeve 3 and the outer wall surface of the cylindrical heat pipe 1 to form a spiral liquid channel 7 , the liquid connecting pipe 5 can be arranged on the side of the outer sleeve 3 or on the sleeve cover 4 . The deflector 2 not only increases the heat dissipation area, but also increases the liquid flow rate and disturbance, strengthens the heat absorption of the cooling liquid, reduces the thermal resistance, and has a better heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com