Vehicle body CAN bus controlling system

A CAN bus, automobile body technology, applied in the field bus control system field, can solve the problem of no CAN technology, and achieve the effect of simple wiring, convenient function expansion, and improved equipment level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

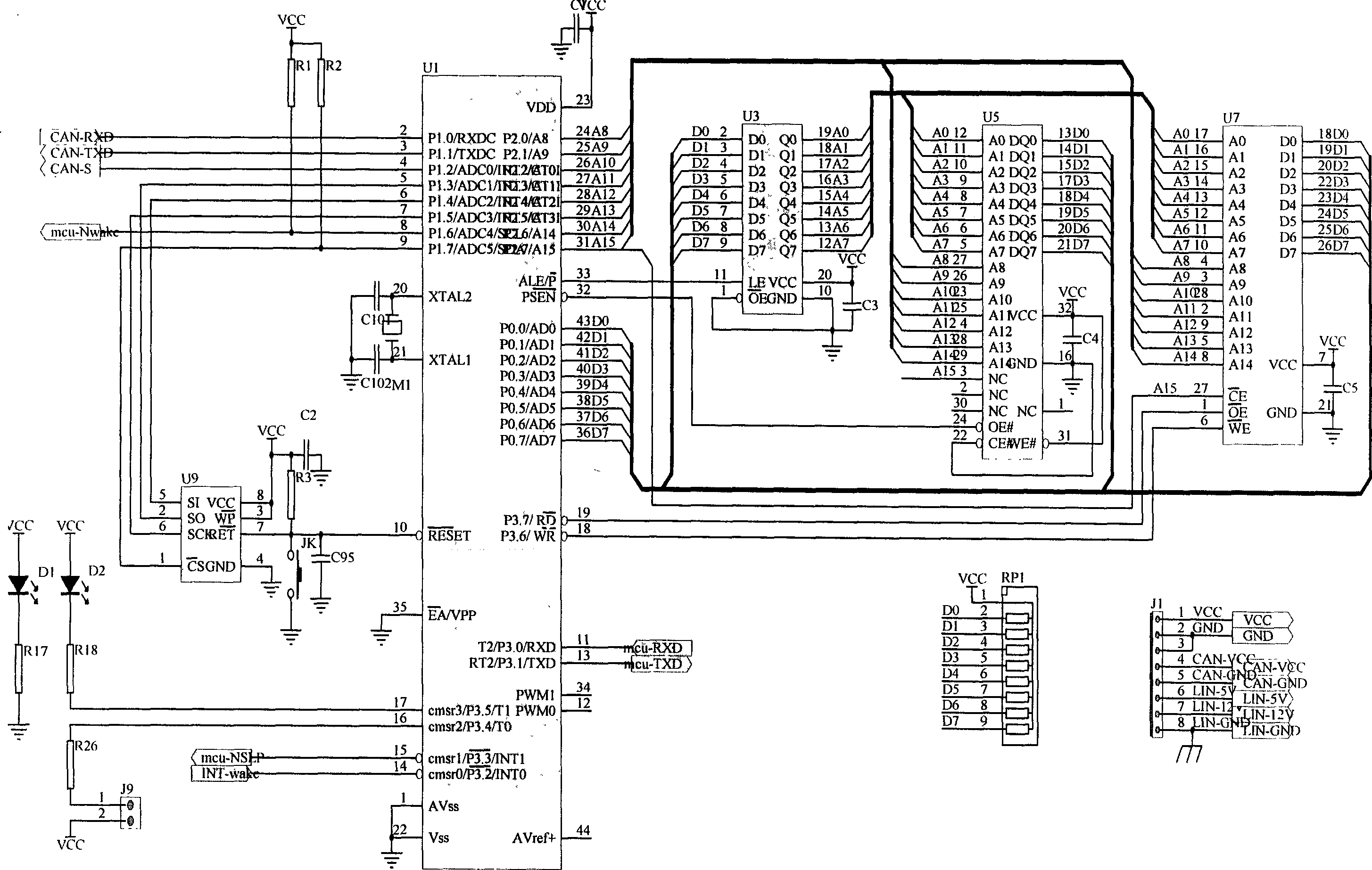

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

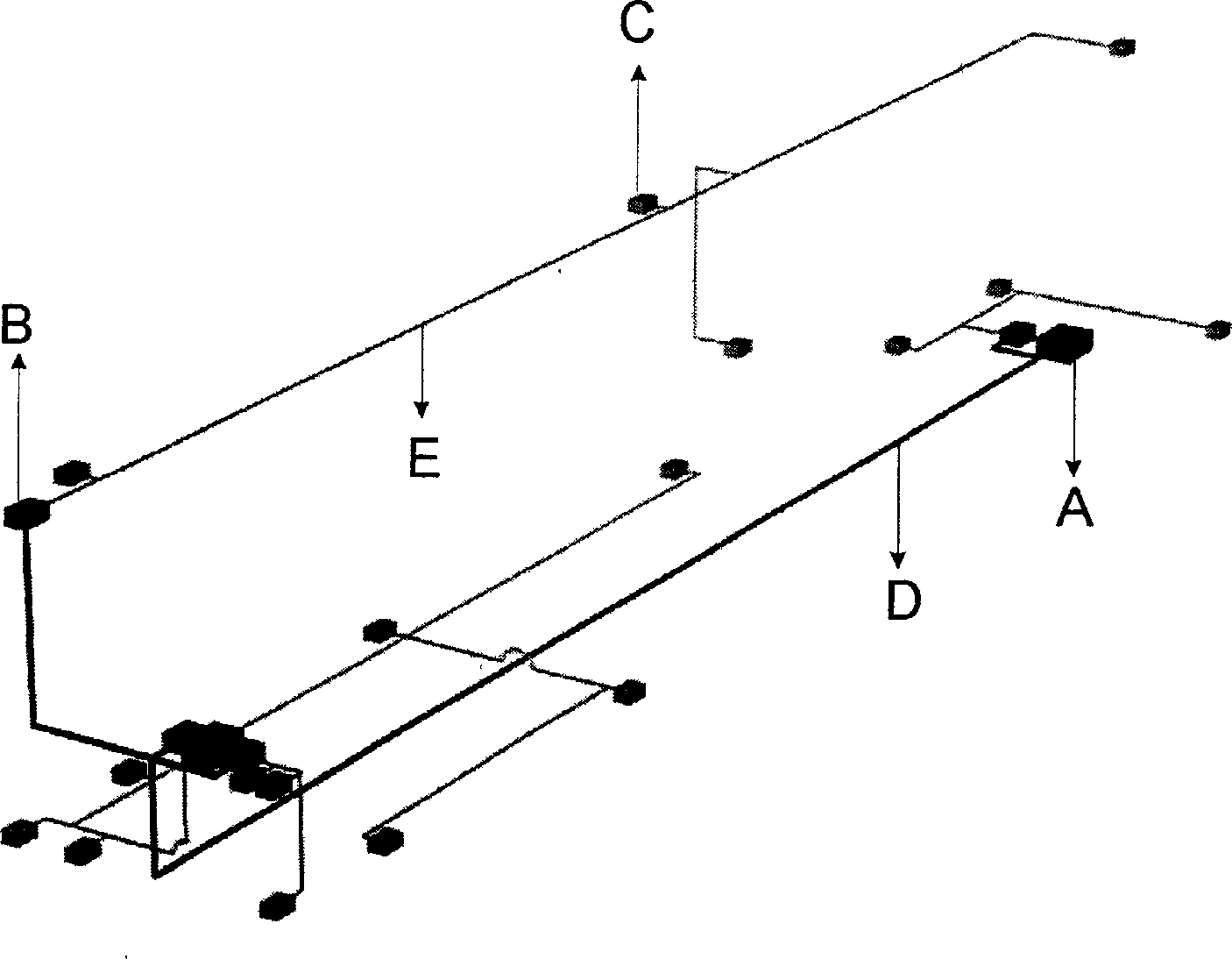

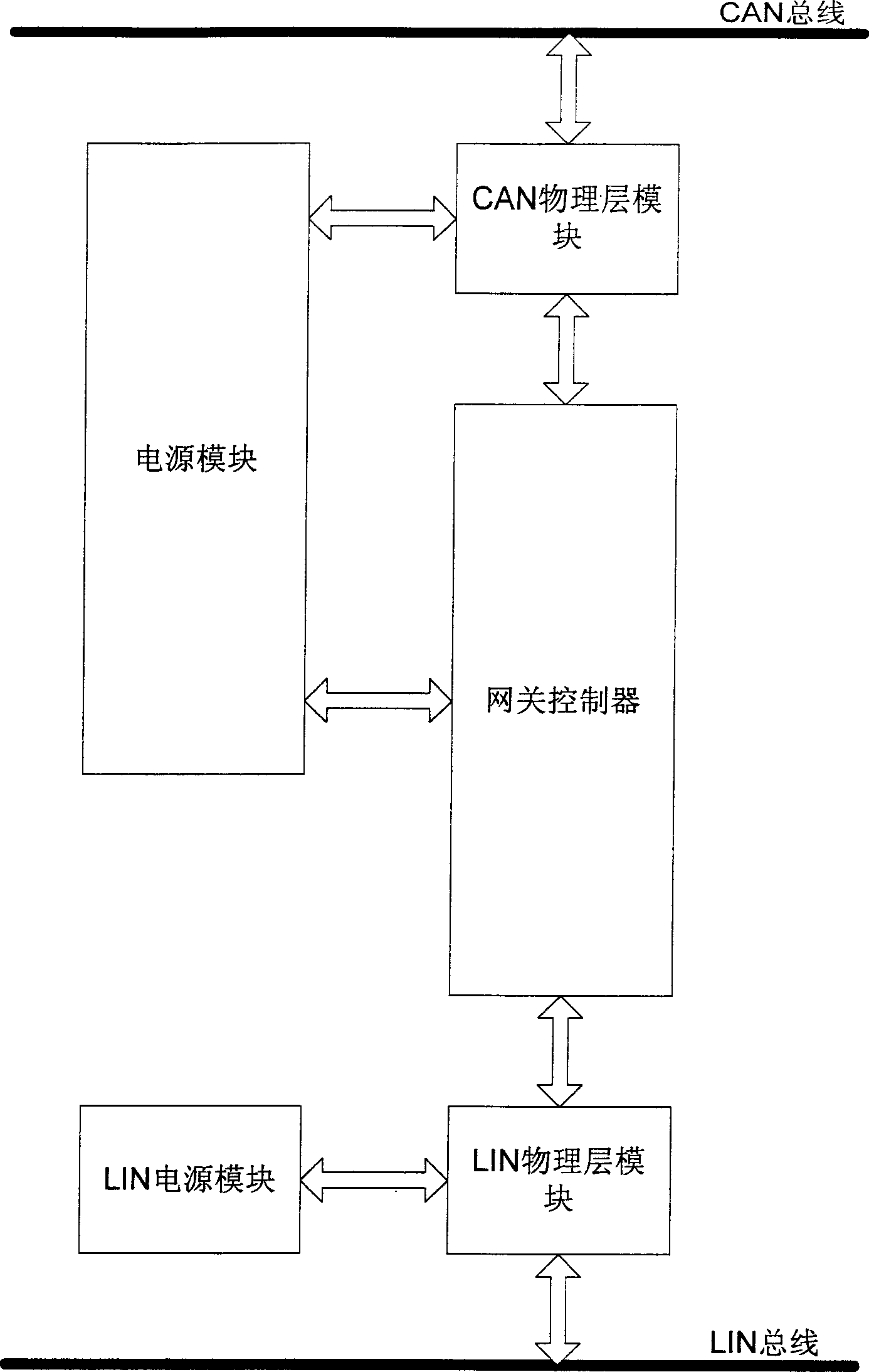

[0067] Such as figure 1 Shown, the present invention comprises CAN-LIN gateway, CAN control module and LIN control module three parts, namely:

[0068] -CAN-LIN gateway, connects two physically independent CAN networks or LIN networks, and realizes data exchange between high-speed and low-speed network systems, runs CAN bus protocol and LIN bus protocol, and completes it through CAN control module or LIN control module Distributed control of automotive electronic components, transmit LIN messages to CAN network, where LIN devices work as slave devices, received LIN messages will be transmitted to CAN network, LIN identifiers are converted into CAN identifiers, LIN The data is transmitted through the CAN object; when the CAN-LIN gateway requests transmission, the CAN identifier is converted into a LIN identifier, the data of the CAN object is stored in the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com