Connection structure between drying pipeline and water tub of drum washing machine

A technology for drum washing machines and drying pipes, which is applied to washing machines with containers, household clothes dryers, washing devices, etc. It can solve the problems of reducing drying efficiency, power consumption, and loss of trust, and achieves a reliable sealing structure and improved drying efficiency. The effect of dry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred examples of the present invention will be described in detail below with reference to the accompanying drawings.

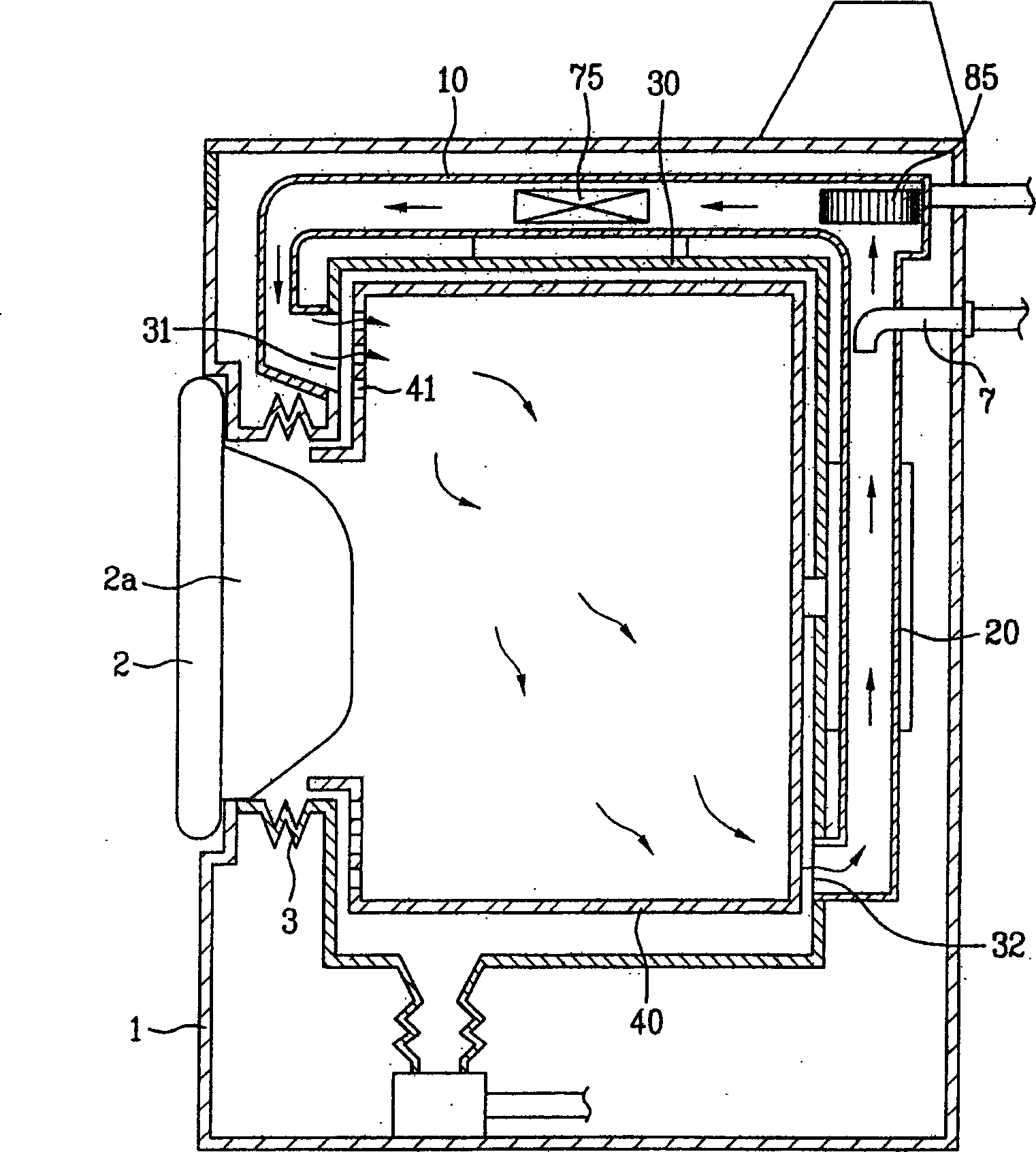

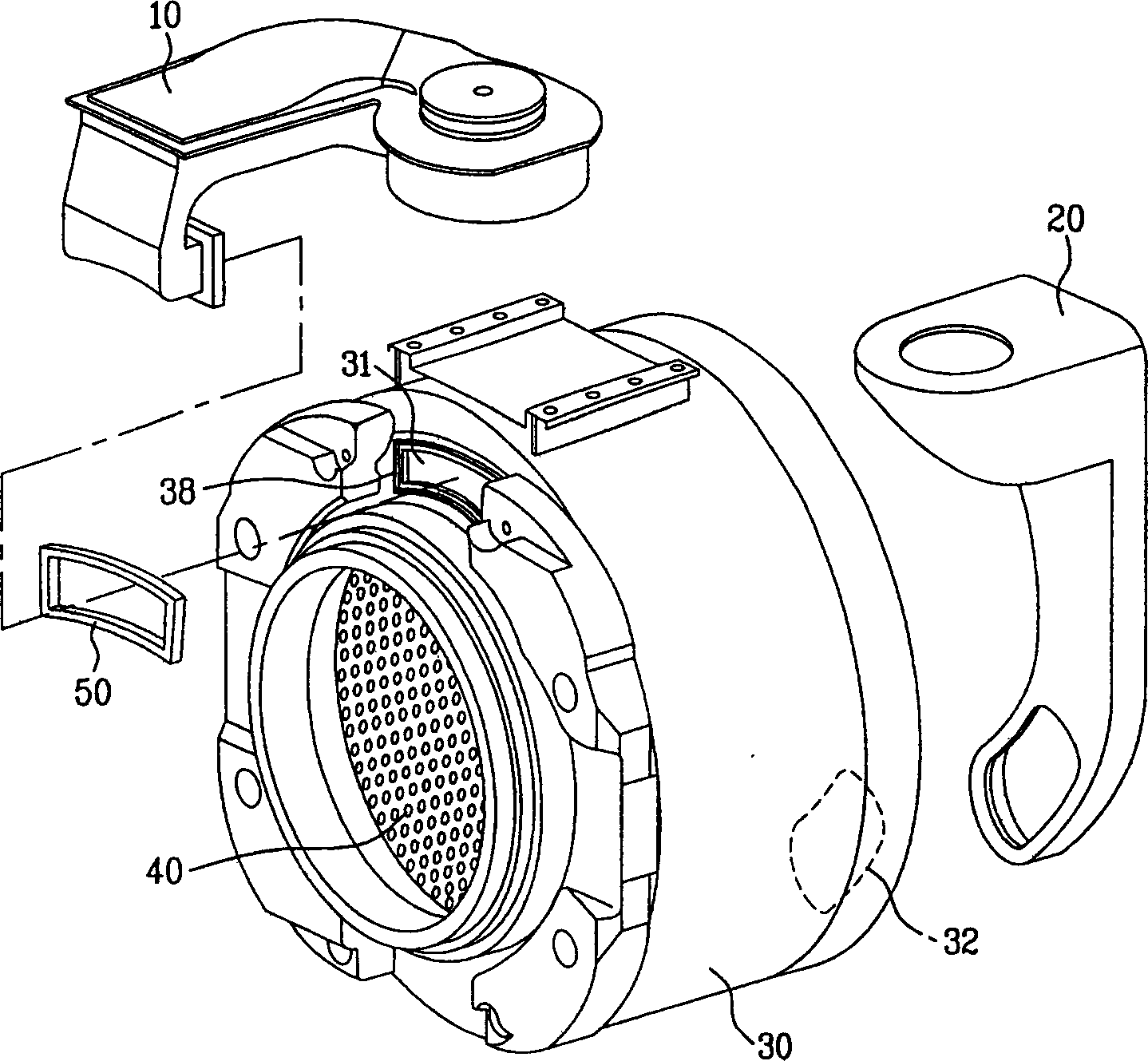

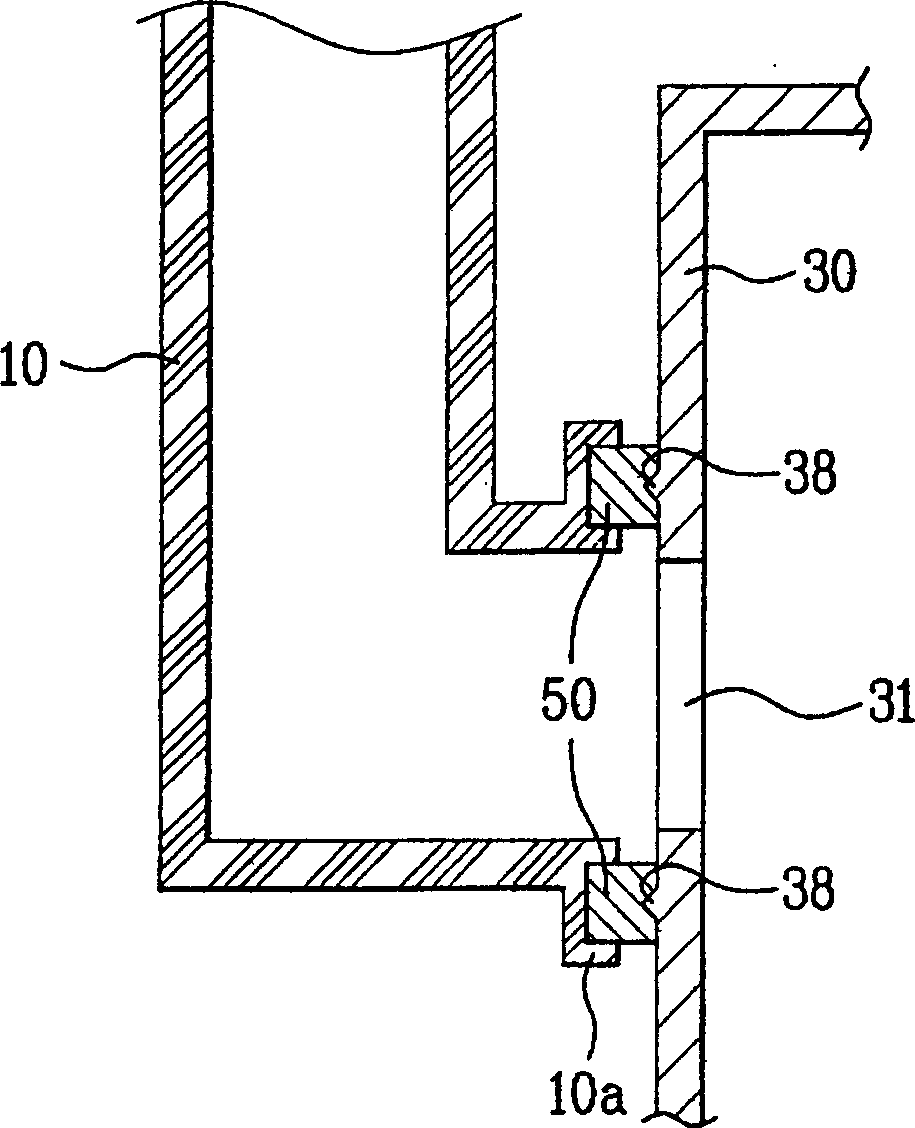

[0040] figure 2 It is an exploded side view of the drying pipe and the condensing pipe connected to the bucket in a drum washing machine of an example of the present invention, image 3 It is a sectional view of main parts of a drum washing machine according to an example of the present invention, showing an assembled structure after a water tub with a sealing member inserted therein is connected to a drying pipe.

[0041] In the present invention, except for the connection structure between the drying pipeline and the bucket, other structures are the same as those of the prior art, and these parts have been described in detail above, so they are omitted here. And in the following description, except for the connection structure between the drying pipeline and the bucket, the symbols in other parts of the drum washing machine adopt the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com