Inner container of electric water heater with improved structure and its production process

An electric water heater and a manufacturing process technology, which are applied in the field of electric water heater inner tank and its manufacturing process, electric water heater inner tank with improved structure and its manufacturing process, can solve the problems of no porcelain area in the inner tank, lack of porcelain, great difficulty, etc. Achieve the effect of eliminating quality and safety hazards, mixing hot and cold water evenly, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

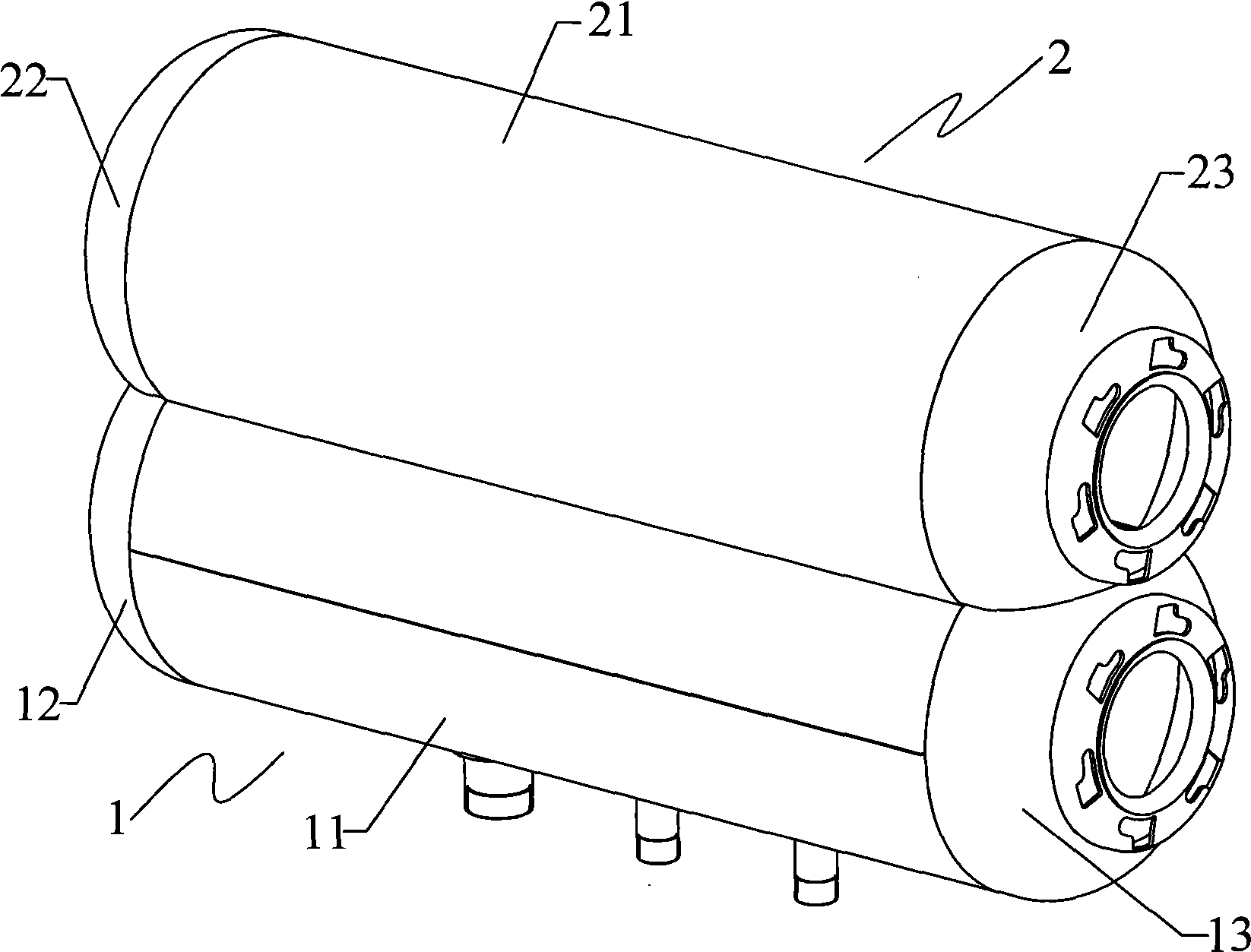

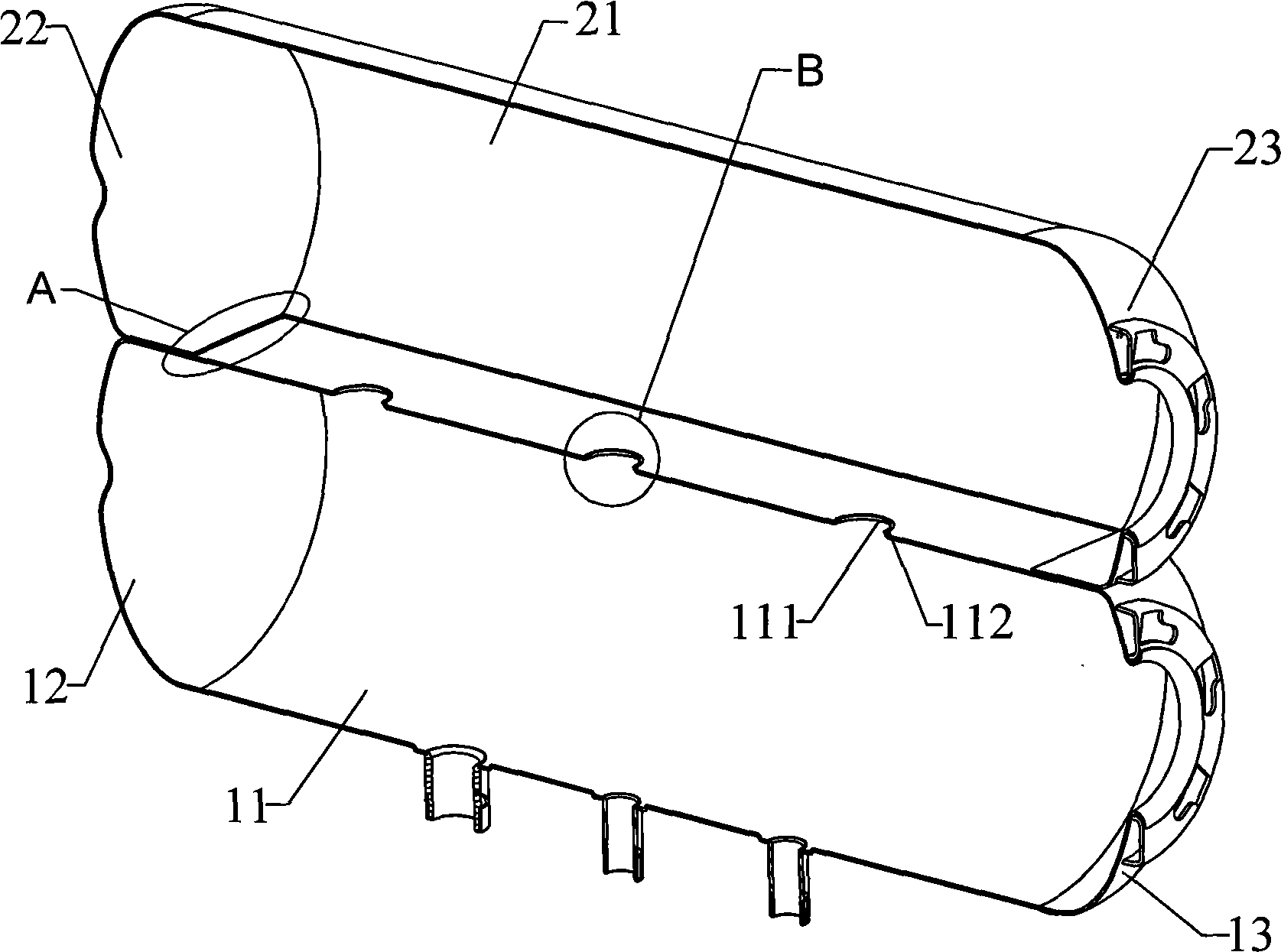

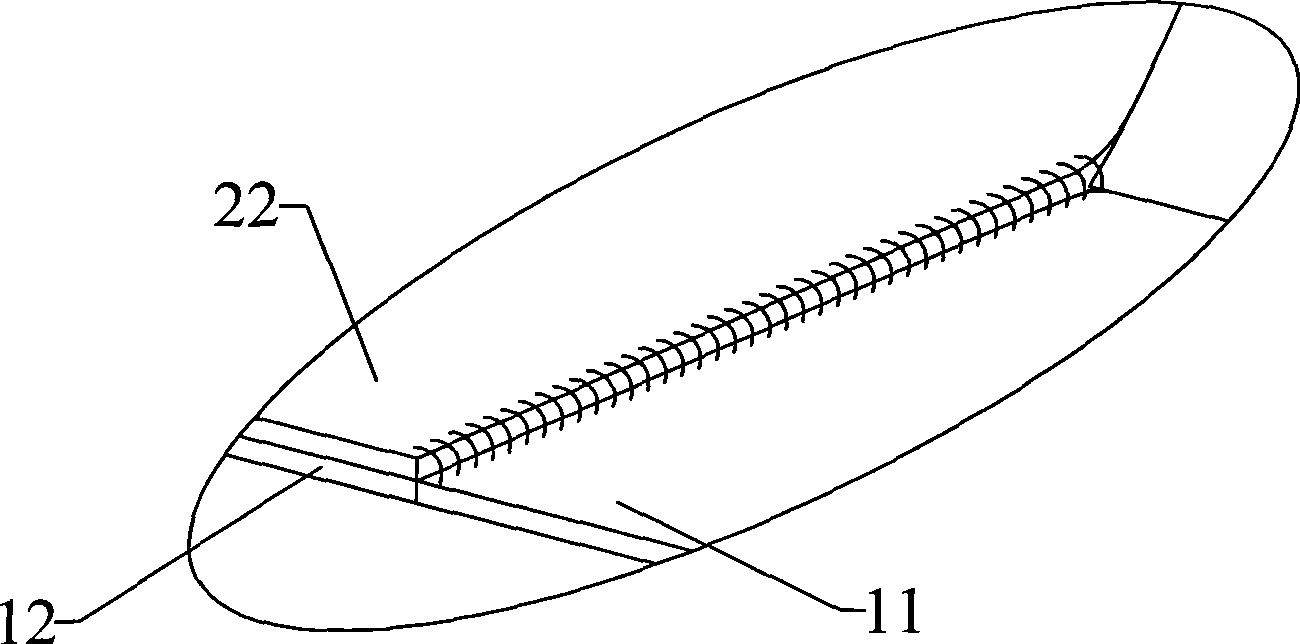

[0031] Such as figure 1 As shown in -4, the electric water heater liner of the present invention includes a first liner 1 and a second liner 2, the first liner 1 and the second liner 2 are connected, and the first liner 1 The two ends of the middle ring 11 are respectively provided with a first airtight end cover 12 and a first flange end cover 13, and the two ends of the middle ring 21 of the second liner 2 are respectively provided with a second airtight end cover 22 and a second flange end Cover 23.

[0032] The cross-section of the middle ring 11 of the first inner tank 1 is "D" type, and the surface where the "D" type vertical side is located is provided with three water holes 111 with flanges 112, the first closed end cover 12 and the first flange The end caps 13 are respectively welded and fixed to the middle ring 11 inside or outside. The cross-section of the middle ring 21 of the second inner tank 2 is "C" shape, and the second airtight end cover 22 and the second f...

Embodiment 2

[0036] Such as Figure 5 As shown in -8, the difference between the embodiment described in this embodiment and embodiment 1 is that the cross section of the middle circle 21 of the second liner 2 in this embodiment is "D" type, and the "D" type vertical side The surface is provided with a water hole 211 adapted to fit with the water hole 111 of the first inner container 1, and the second inner container water hole 211 is provided with a flange 212 that is docked and matched with the first inner container water hole 111. The flange 212 faces the inside of the second inner container 2 , and is welded and fixed inside the second inner container 2 after being butted with the flange 112 of the water passage hole 111 of the first inner container.

[0037] The manufacturing process of the present invention is as follows: First, the first airtight end cover 12 and the first flange end cover 13 are welded and fixed to the first inner tank middle ring 11 inside or outside respectively ...

Embodiment 3

[0039] Such as Figure 9 , 10 As shown, the implementation described in this embodiment is basically the same as that of Example 2, the only difference is that in this embodiment, the water passage hole 111 of the first inner container and the water passage hole 211 of the second inner container are not provided. Flanging, but a sealing rubber ring 31 is worn at the junction of the first liner water hole 111 and the second liner water hole 211, and screwed and fixed by the hollow screw 32 and the nut 33, because the screw 32 is Hollow, so it not only plays the role of fastening connection, but also can be used as water passage. The rest of the structure and manufacturing process are the same as the above-mentioned embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com