Incinerator for medical garbage

A technology of medical waste and incinerator, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of increased operating cost, dependence, large heat loss, etc., and achieve the effect of reducing pollution discharge points and stabilizing the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

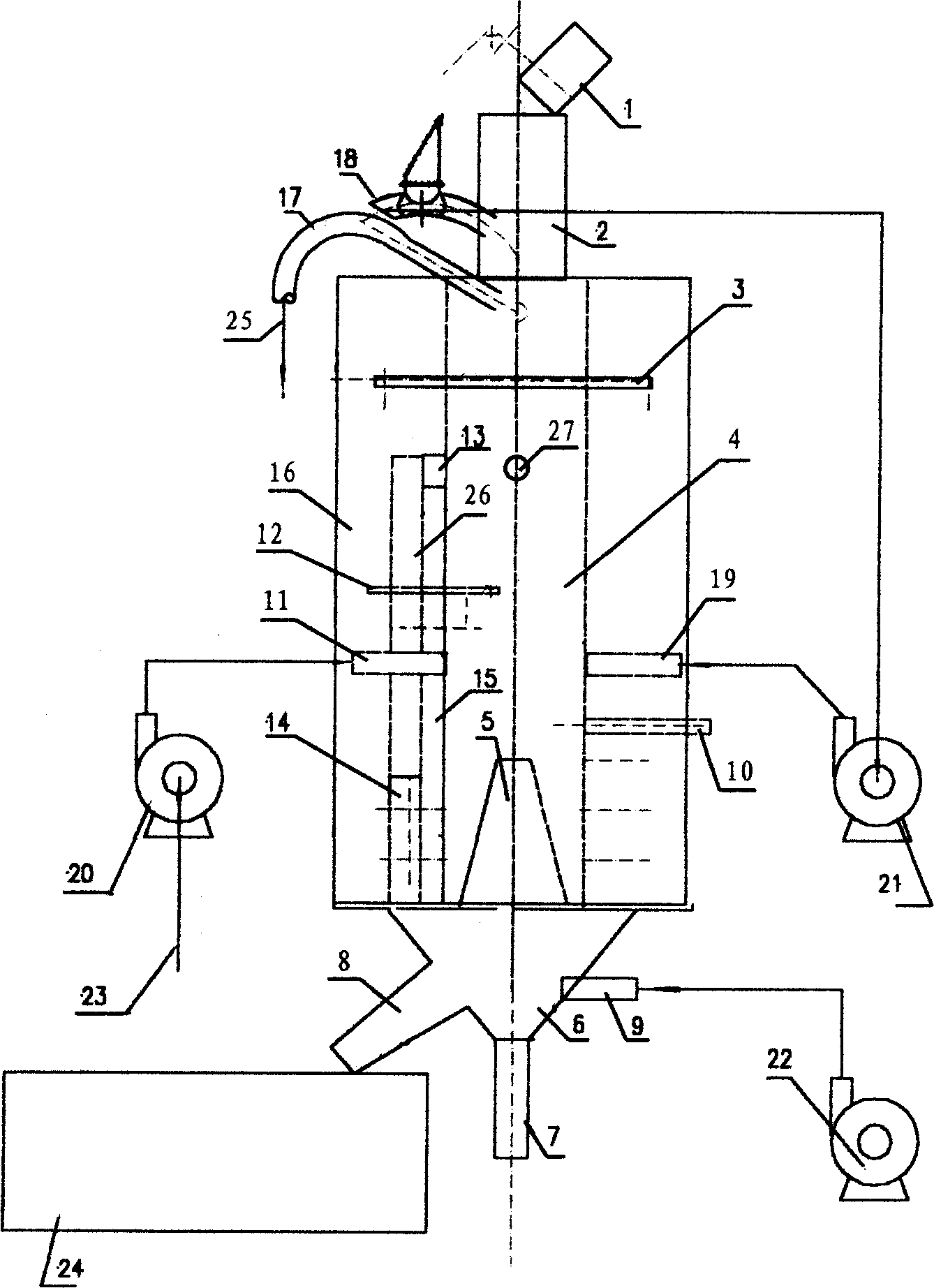

[0017] As shown in the figure, a medical waste incinerator, the furnace body is a vertical cylindrical furnace body, and the top of the furnace is equipped with two air-locking feeding devices, two air-locking feeding devices and a reciprocating lifting feeding device Connected, when the lifting and loading device is on the ground, the opening of the hopper will automatically face up for loading, and when it is lifted to the top of the furnace body, the opening of the hopper will automatically face down for unloading. When unloading, the garbage to be processed will first fall on the previous air lock valve. On the board, when there is a command for unloading, the upper air lock valve is opened, and the garbage falls on the next air lock valve plate, that is, the garbage is in the cavity between the upper and lower air lock valves, and the last air lock valve After the damper valve plate is closed, the next air lock valve plate is opened, and the garbage falls on the double-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com