Assembling device of automobile seat linkage mechanism and its method

A technology for car seats and assembling devices, applied in vehicle seats, special positions of vehicles, vehicle parts, etc., can solve the problems of replacement parts trouble, energy consumption, inability to disassemble, etc. The effect of self-weight and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

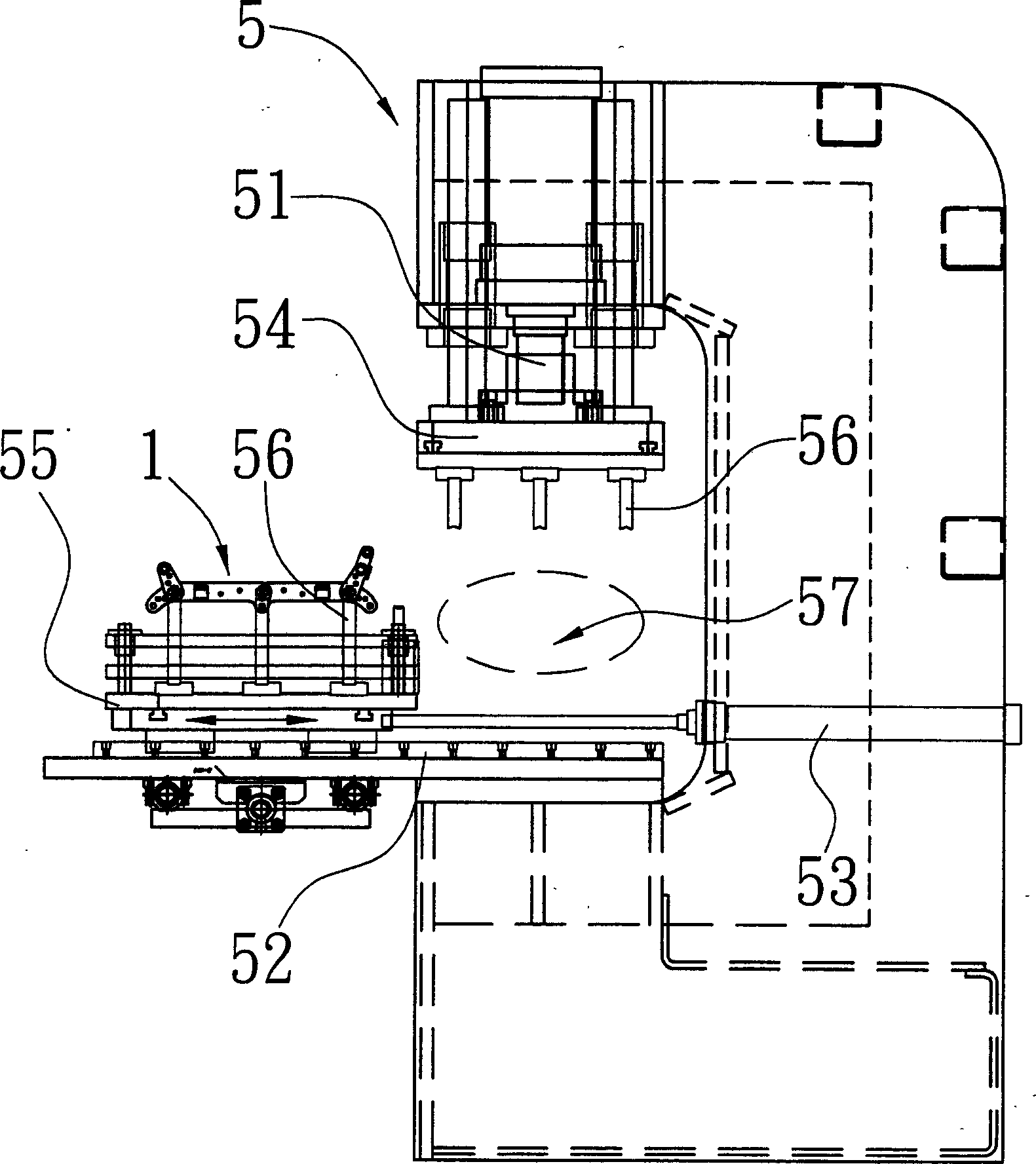

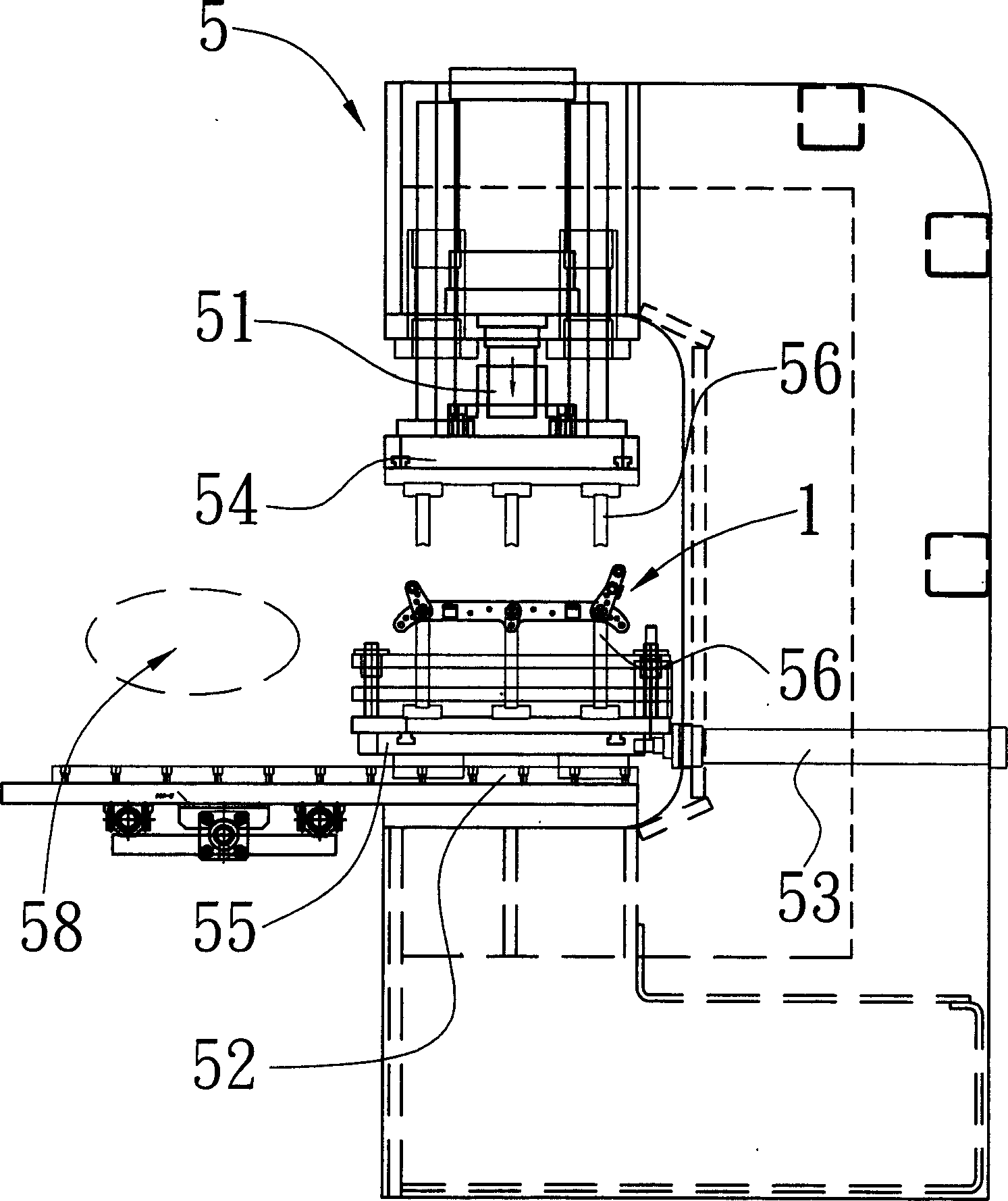

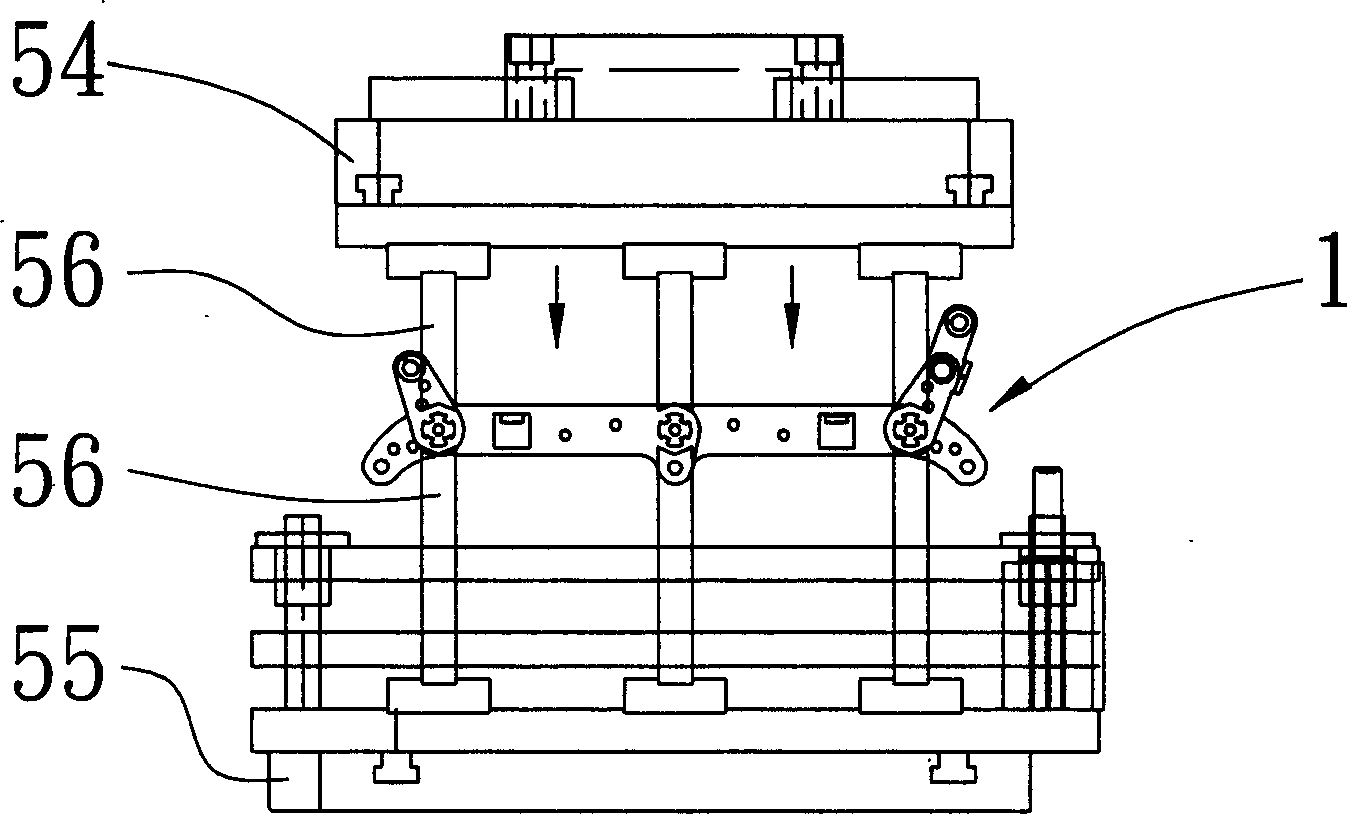

[0032] see Figure 1 to Figure 3 As shown, the assembly device and method of the automobile seat linkage mechanism provided by the present invention mainly include:

[0033] A pressing machine 5, which provides the effect of pressing, includes: an extrusion device 51; a work platform 52; an upper pressing device 54, which is connected with the extrusion device 51, and is provided with a number of extrusion dies 56; Cylinder 53 is fixedly connected with its lower pressing device 55, to provide the effect that lower pressing device 55 moves to discharge area 58 in operation platform 52 pressing area 57; Lower pressing device 55 is provided with several extrusion dies 56 and several support frames (figure not drawn in);

[0034] Four connection plates 2, the two ends of the connection plate 2 are far apart respectively have a perforation 21, and the circumference of the perforation 21 is equidistantly placed with four-toothed external teeth 22, as shown in Figure 8;

[0035] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com